Alkali-free production technology of centralite II

A production process and organic solvent technology, applied in the field of alkali-free production process of No. II medium fixed agent, can solve the problems of low product quality and difficult handling, and achieve the effect of small color number and high product content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1), add N-methylaniline, carbonyl chloride and organic solvent in the reaction vessel at a molar ratio of 2:1, the acylation reaction temperature is 60°C, and the acylation reaction time is 4 hours, and the reaction generates N-methyl-N- Phenylcarbamoyl chloride and a small amount of N-methylaniline.

[0019] (2), continue to add N-methylaniline in the acylating liquid of step (1) gained, make N-methylaniline and N-methyl-N-phenylcarbamoyl chloride generate urea reaction, form urea reaction The temperature is 120°C, and the reaction time of urea formation is 10 hours, and the crude product of No. II medium-fixing agent is obtained.

[0020] (3), chlorobenzene is removed under reduced pressure, and the cut N-methylaniline before the distillation is used as the next cycle feed intake, and is distilled at a vacuum degree of -0.090MPa and a kettle temperature of 200° C. to obtain the final product No. II as a neutralizing agent.

Embodiment 2

[0022] (1), add N-methylaniline, carbonyl chloride and organic solvent in the reaction vessel at a molar ratio of 2.05:1, the acylation reaction temperature is 70°C, and the acylation reaction time is 5 hours, and the reaction generates N-methyl-N- Phenylcarbamoyl chloride and a small amount of N-methylaniline.

[0023] (2), continue to add N-methylanilino group in the acylation liquid of step (1) gained, make N-methylaniline and N-methyl-N-phenylcarbamoyl chloride generate urea reaction, form urea The reaction temperature is 130°C, and the urea formation reaction time is 12 hours, and the crude product of No. II neutralizing agent is obtained.

[0024] (3), chlorobenzene is removed under reduced pressure, and the cut N-methylaniline before distillation is used as the feed intake for the next cycle, and is distilled at a vacuum degree of -0.091MPa and a kettle temperature of 210° C. to obtain the final product No. II as a neutralizing agent.

Embodiment 3

[0026] (1), add N-methylaniline, phosgene and organic solvent in a molar ratio of 2.1:1 in the reaction vessel, the acylation reaction temperature is 80°C, the acylation reaction time is 6 hours, and the reaction generates N-methyl-N- Phenylcarbamoyl chloride and a small amount of N-methylaniline.

[0027] (2), continue to add N-methylanilino group in the acylation liquid of step (1) gained, make N-methylaniline and N-methyl-N-phenylcarbamoyl chloride generate urea reaction, form urea The reaction temperature is 140°C, and the urea formation reaction time is 15 hours, and the crude product of No. II medium-fixing agent is obtained.

[0028] (3), chlorobenzene is removed under reduced pressure, and the cut N-methylaniline before the distillation is used as the feed intake for the next cycle, and is distilled at a vacuum degree of -0.092MPa and a kettle temperature of 220° C. to obtain the final product No. II as a neutralizer.

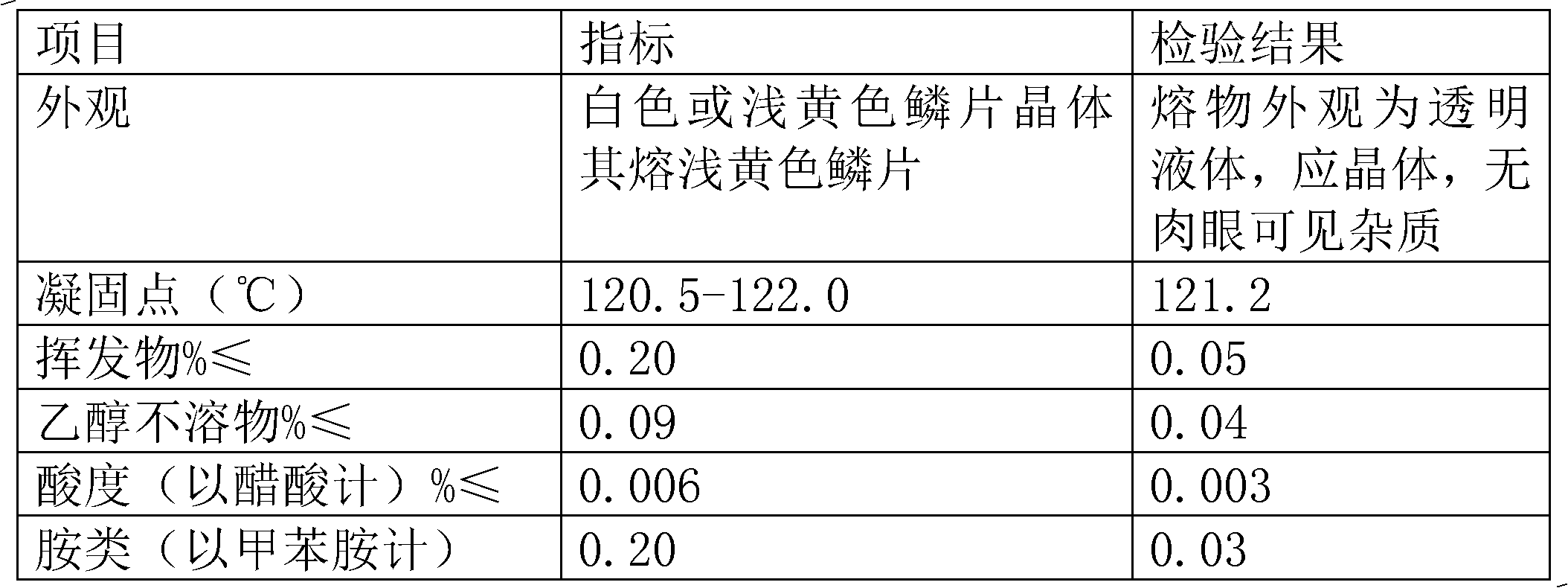

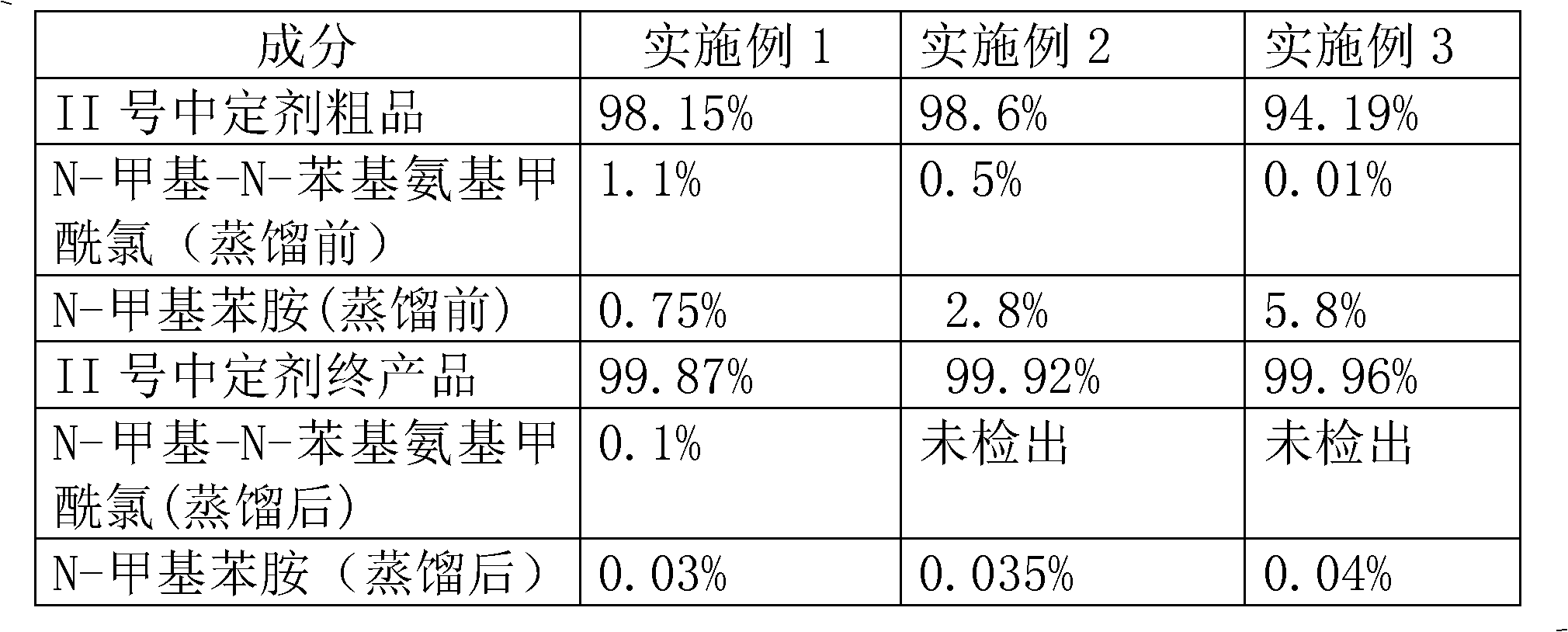

[0029] The detection results of three embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com