Vinyl ester resin, vinyl ester resin compound and preparation method thereof

A vinyl ester resin and composition technology, applied in the field of vinyl ester resin, can solve problems such as large gas volume, and achieve the effects of reducing the amount of bubbles, simplifying the curing process, and shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

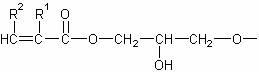

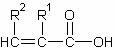

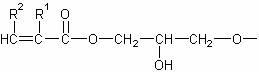

[0047] The preparation method of the above -mentioned ethylene ester resin of the present invention is as follows: a mixture containing epoxy structures and unsaturated one -mout the carboxylic acid for opening a ring polymerization reaction. While the reaction of the opening of the ring, compared to the reaction of the 100 weight portion,Things, further add 0.01 to 10 unsaturated dual carboxylic acids.

[0048] Among them, a mixture containing epoxy structures and unsaturated one yuan carboxylic acid Moore is preferably 1 to 0.8 to 1.2, and it is best to be 1 to 0.9 to 1.1.

[0049] The compounds containing epoxy structures can be bisphenol -A -type epoxy resin, bisphenol -F -type epoxy resin, phenol -type epoxy resin, tetrazabine bisphenol epoxy resin, and rubber -modified epoxy resinAny type, but not limited to the above choices.

[0050] The unsaturated unit acid that can be used in the opening polymerization reaction can be used in one of one of the unsaturated unit acids, wh...

Embodiment 1

[0061] 0.1 g ingine binary acid, 100g of bisphenol A type A type of ethylene -based ethylene -based ethylene ethylene -based ethylene ethylene -based, mixed uniformly to prepare a bisphenol -type ethylene ester resin.

Embodiment 2

[0063] 0.5g of antibutonic acid, 100g of bisphenol -type ethylene -based ethylene -based ethylene -based ethylene ethylene -based ethylene ethylene -based, mixed uniformly to prepare a bisphenol A type ethyl ester resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com