Preparation method of super-sustained release ester-ether crosslinking polycarboxylic acid water reducer

A kind of polycarboxylic acid-like, super slow-release technology, applied in the field of concrete admixtures, which can solve the problems of complex production process, long esterification cycle and performance gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

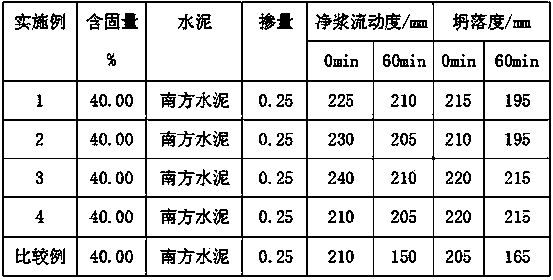

Examples

Embodiment 1

[0027] (1) Synthesis of macromonomers: In a well-sealed reaction kettle, under continuous stirring, 1500 kg of methoxypolyethylene glycol with a molecular weight of 1200, 1.5 kg of hydroquinone, 0.5 kg of phenothiazine, 20kg of p-toluenesulfonic acid, heated to 80-90°C, stirred for 30min, fully dissolved, then slowly added 550kg of methacrylic acid, and started to heat up, when the temperature reached 100°C, close all the ventilation valves of the reaction kettle, and feed nitrogen Keep the pressure in the reactor at 0.1MPa, continue to heat up to 125-130°C, and keep warm at this temperature for 6 hours. After the reaction is completed, polyethylene glycol monomethyl ether methacrylate is obtained, which is polycarboxylate superplasticizer intermediate. After the reaction, the esterification rate was measured to be 99.55%.

[0028] (2) Synthesis of polycarboxylate superplasticizer: Add 350kg of allyl polyoxyethylene ether with a molecular weight of 1200, 55.23kg of sodium met...

Embodiment 2

[0030] (1) Synthesis of macromonomers: In a well-sealed reaction kettle, under continuous stirring, 1500 kg of methoxypolyethylene glycol with a molecular weight of 1200, 1.5 kg of hydroquinone, 0.5 kg of phenothiazine, 20 kg of p-toluenesulfonic acid, heated to 80-90 °C, stirred for 30 minutes, fully dissolved, then slowly added 550 kg of methacrylic acid, and began to heat up, when the temperature reached 100 °C, close all the ventilation valves of the reactor, and feed Nitrogen keeps the pressure in the reactor at 0.1 MPa, continues to heat up to 125-130°C, and keeps at this temperature for 6 hours. After the reaction is completed, polyethylene glycol monomethyl ether methacrylate is obtained, which is polycarboxylate water-reduced agent intermediates. After the reaction, the esterification rate was measured to be 99.55%.

[0031] (2) Synthesis of polycarboxylate superplasticizer: Add 750 kg of methallyl polyoxyethylene ether with a molecular weight of 2400, 55.23 kg of so...

Embodiment 3

[0033](1) Synthesis of macromonomers: In a well-sealed reaction kettle, under continuous stirring, 1500 kg of methoxypolyethylene glycol with a molecular weight of 1200, 1.5 kg of hydroquinone, 0.5 kg of phenothiazine, 20kg of p-toluenesulfonic acid, when heated to 80-90°C, stir for 30min to fully dissolve, then slowly add a mixture of 550kg of methacrylic acid and 1.06kg of hydroxyethyl methacrylate, and start to heat up until the temperature reaches 100°C , close all the ventilation valves of the reactor, and feed nitrogen to keep the pressure in the reactor at 0.1MPa, continue to heat up to 125-130°C, and keep warm at this temperature for 6 hours. After the reaction is completed, polyethylene glycol monomethyl ether methyl Acrylic acid ester is the intermediate of polycarboxylate superplasticizer. After the reaction, the esterification rate was measured to be 99.84%.

[0034] (2) Synthesis of polycarboxylate superplasticizer: Add 750 kg of methallyl polyoxyethylene ether w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com