Sleeve type photobiological reaction system for culturing microalgae on scale by utilizing waste gas and waste heat

A technology of photobioreaction and photobioreactor, which is applied in the field of casing-type photobioreaction system, can solve the problems of not being too long (not more than 80m, hindering large-scale cultivation, and not being able to effectively control the growth environment of microalgae, etc. Achieve the effect of solving light attenuation and light suppression, improving light energy utilization rate, and weakening light attenuation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

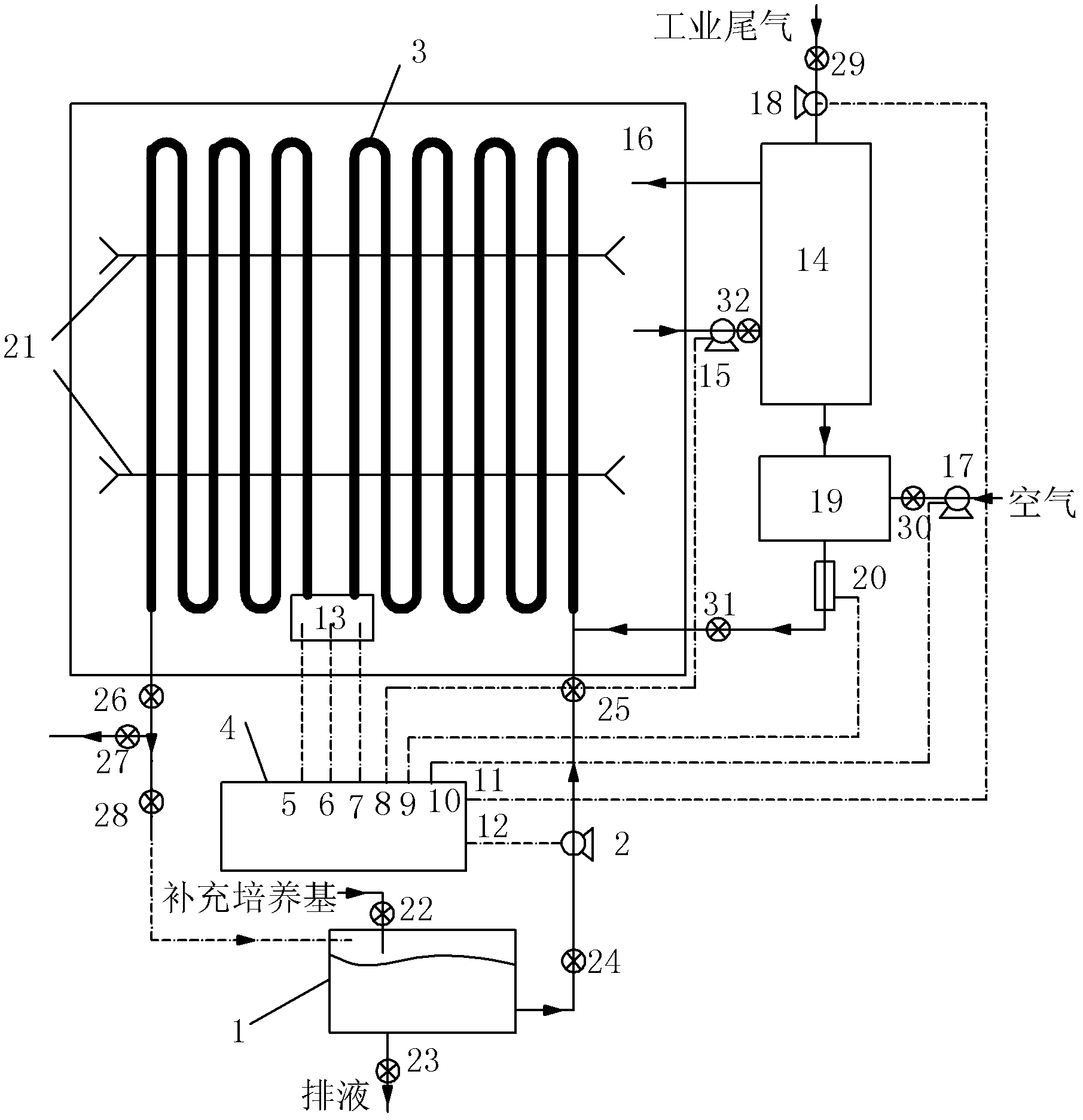

[0062] like figure 1 The sleeve-type photobioreactor system of serial culture reactors for continuous culture is shown.

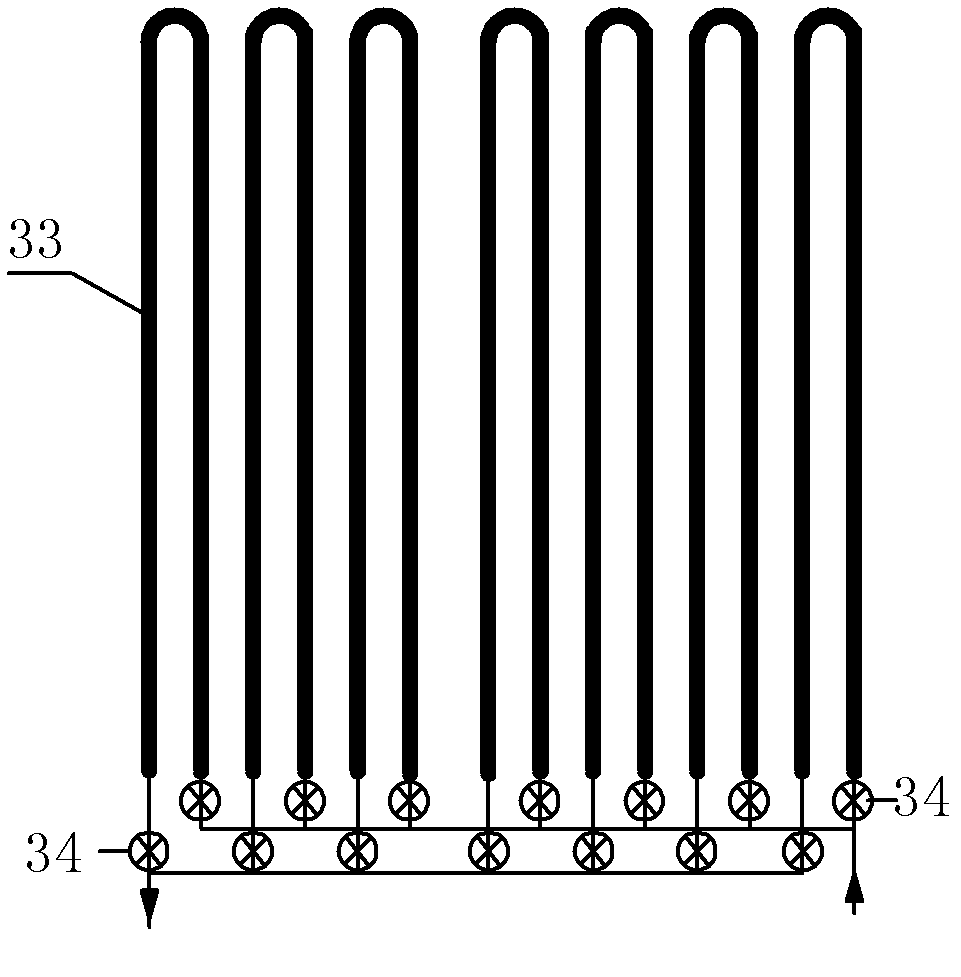

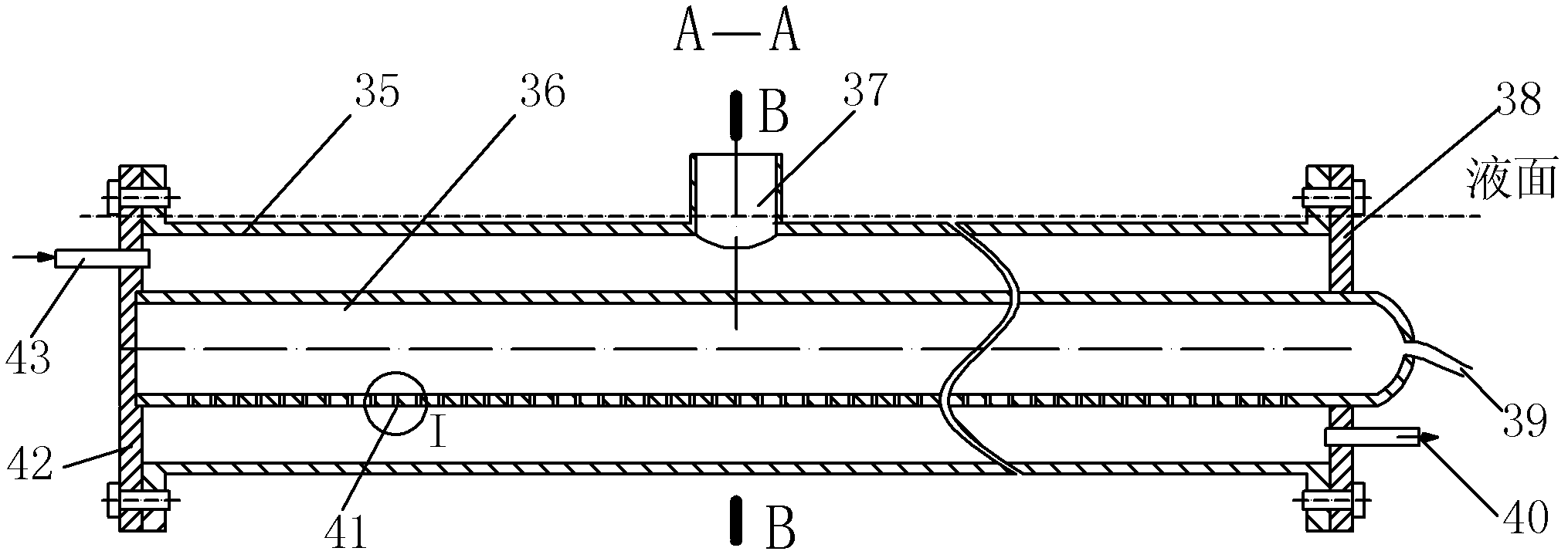

[0063] First, in the production of CO-enriched 2 Find a suitable site near the factory, build a temperature-controlled water pool 16, install brackets 21 every 2m according to the layout of the pipelines in the pool, fix 14 sets of sleeve-type photobioreactors on the brackets 21, and pass U-shaped pipelines connection, each pipeline is connected end to end to form a series mode, and a test box 13 is connected in the middle, and a temperature sensor 5, a pH sensor 6, and a dissolved oxygen (DO) sensor 7 are housed inside to form a series culture pipe section 3 of this system. The 14 sets of tube-type photobioreactors have the same structure, such as Figure 3-1 As shown, the casing structure with built-in aeration tube is adopted, wherein: the inner diameter of the transparent outer tube 35 is 200 mm, and the material is glass; the outer diameter of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com