Size mixture for sizing filament, and preparation method and application of size mixture

A technology of mixture and sizing, applied in textile and paper making, fiber type, fiber processing and other directions, can solve the problems of sizing adhesion, insufficient abrasion resistance, moisture absorption of sizing, and large required amount, etc., to achieve performance improvement, The effect of easy desizing and reduced sizing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Preparation of water-soluble polyester:

[0046] 95.8kg terephthalic acid, 12kg isophthalic acid, 15.6kg dimethyl isophthalate-5-sodium sulfonate, 8kg 1,4-cyclohexanedicarboxylic acid, 40.1kg ethylene glycol, 16.6kg new Put pentylene glycol and 50g of isopropyl titanate into the reaction kettle, replace the air with nitrogen to discharge the air, stir and raise the temperature, and react at 220-255°C. When the by-products reach the theoretical value, reduce the pressure and polymerize, the reaction temperature is 250-280 ° C, stop the reaction after reaching the end point, fill with nitrogen to eliminate the vacuum, and extrude the material.

[0047] 2. Synthesis of acrylic paste:

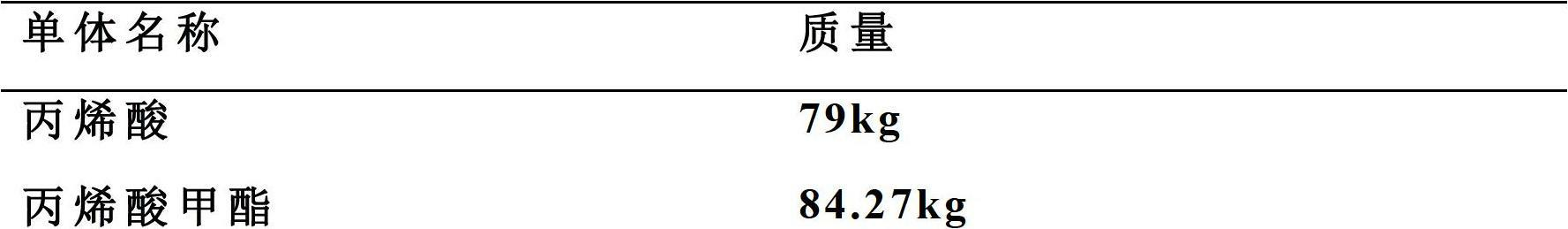

[0048] Mix the following monomers well:

[0049]

[0050]

[0051]First add the emulsifier sodium lauryl sulfate (2-4% of the total amount of monomers) and water (3.2 times the total amount of monomers) into the reaction kettle equipped with a reflux condenser, and stir evenly. T...

Embodiment 2

[0054] 1. Preparation of water-soluble polyester:

[0055] 105kg terephthalic acid, 23kg isophthalic acid, 13.2kg dimethyl isophthalate-5-sodium sulfonate, 5kg adipic acid, 53kg ethylene glycol, 23.4kg1,4-butanediol, 46g di Put butyltin oxide and zinc acetate into the reaction kettle, replace the air with nitrogen, heat up with stirring, and react at 220-255°C. When the by-products reach the theoretical value, reduce the pressure and polymerize, the reaction temperature is 250-280 ° C, stop the reaction after reaching the end point, fill with nitrogen to eliminate the vacuum, and extrude the material.

[0056] 2. Synthesis of acrylic paste:

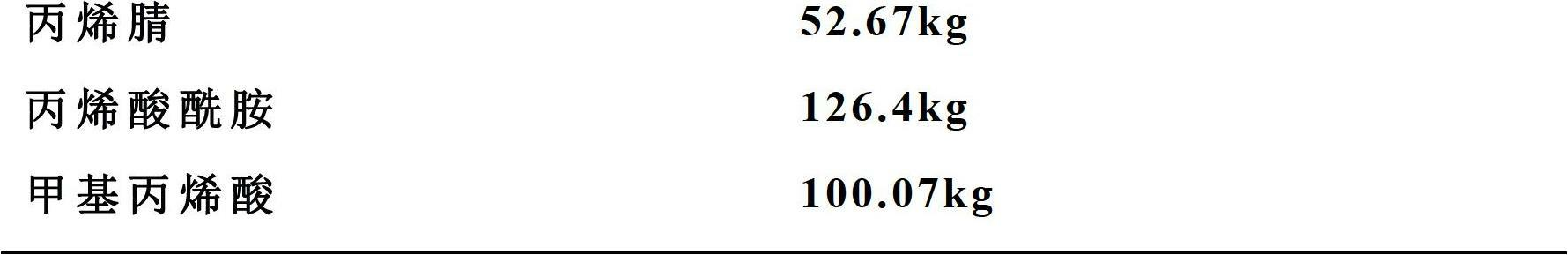

[0057] Mix the following monomers well:

[0058]

[0059] First add the emulsifier sodium lauryl sulfate (2-4% of the total amount of monomers) and water (3.2 times the total amount of monomers) into the reaction kettle equipped with a reflux condenser, and stir evenly. Then add the previously mixed monomer and initiator (potassium ...

Embodiment 3

[0062] 1. Preparation of water-soluble polyester:

[0063] 95.8kg terephthalic acid, 12kg isophthalic acid, 15.6kg dimethyl isophthalate-5-sodium sulfonate, 8kg 1,4-cyclohexanedicarboxylic acid, 40.1kg ethylene glycol, 16.6kg new Put pentylene glycol and 50g of isopropyl titanate into the reaction kettle, replace the air with nitrogen to discharge the air, stir and raise the temperature, and react at 220-255°C. When the by-products reach the theoretical value, reduce the pressure and polymerize, the reaction temperature is 250-280 ° C, stop the reaction after reaching the end point, fill with nitrogen to eliminate the vacuum, and extrude the material.

[0064] 2. Synthesis of acrylic paste:

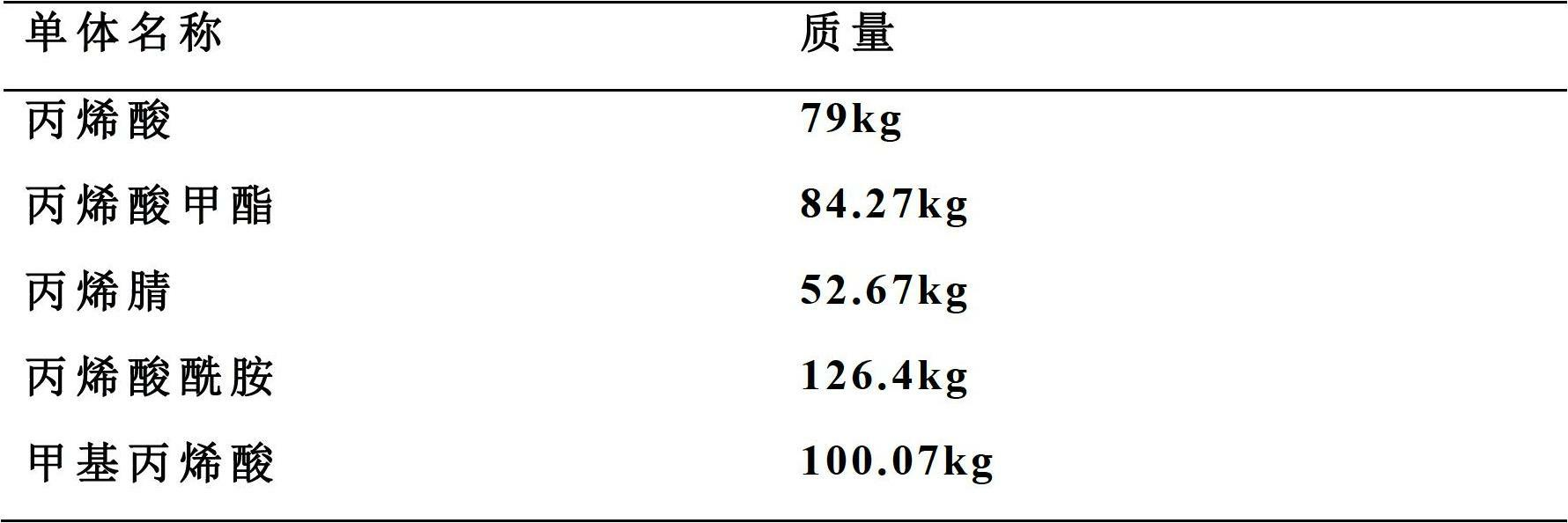

[0065] Mix the following monomers well:

[0066]

[0067] First add the emulsifier sodium lauryl sulfate (2-4% of the total amount of monomers) and water (3.2 times the total amount of monomers) into the reaction kettle equipped with a reflux condenser, and stir evenly. Then add the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com