Polyacrylic acid textile pulp

A technology of textile pulp and polyacrylic acid, applied in the field of polyacrylic acid textile pulp and textile pulp, can solve the problems of hygroscopicity, high re-viscosity, inconvenient use, poor fluidity, etc., and achieves good extensibility, low viscosity, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

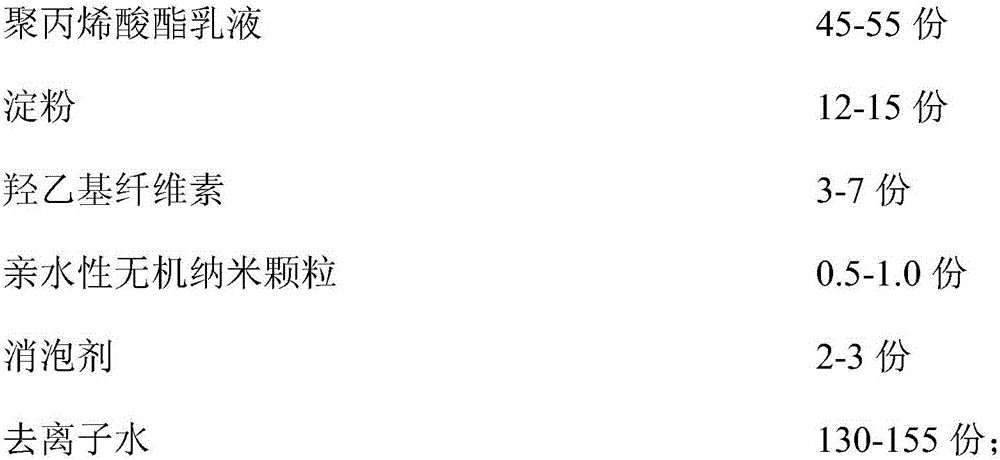

[0047] A textile slurry prepared from the following raw materials in parts by weight:

[0048]

[0049]

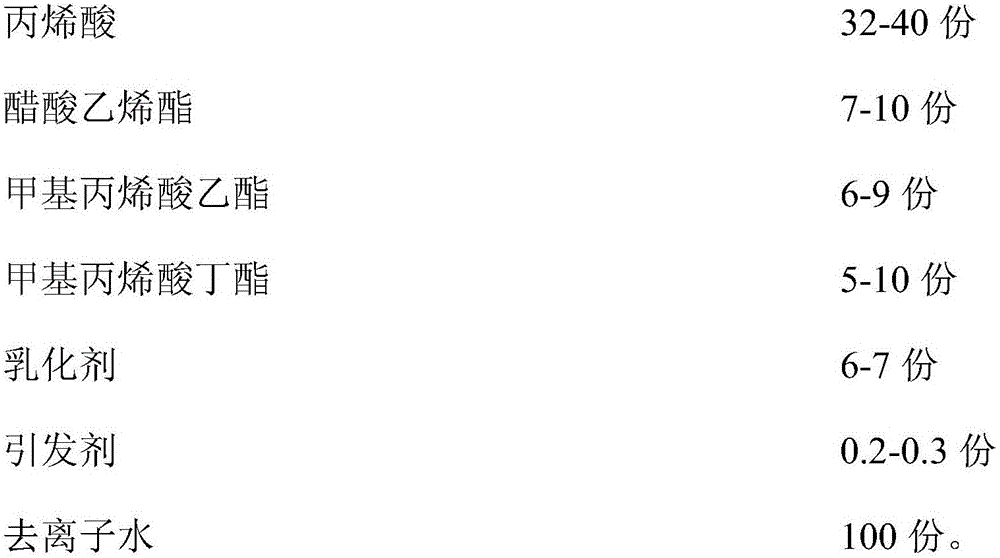

[0050] Wherein, the polyacrylate emulsion is prepared from the following raw materials in parts by weight:

[0051]

[0052] The emulsifier is sodium lauryl sulfate.

[0053] The initiator is ammonium persulfate.

[0054] The defoamer is dimethyl silicone oil.

[0055] The hydrophilic inorganic nanoparticles are inorganic nanoparticles whose surfaces are modified by hydroxyl groups, and the inorganic nanoparticles are silica; the particle size of the hydrophilic inorganic nanoparticles is 5-10 nm.

[0056] The preparation method of the polyacrylic acid textile size includes the following steps:

[0057] (1) Mix the formulated amount of polyacrylic acid, vinyl acetate, ethyl methacrylate, butyl methacrylate, emulsifier, initiator and deionized water, and react at 50°C to obtain a polyacrylate emulsion;

[0058] (2) Mix the formula amount of starch, hydroxyethyl cellulose and deionized w...

Embodiment 2

[0061] A textile slurry prepared from the following raw materials in parts by weight:

[0062]

[0063] Wherein, the polyacrylate emulsion is prepared from the following raw materials in parts by weight:

[0064]

[0065] The emulsifier is OP-10.

[0066] The initiator is ammonium persulfate.

[0067] The defoamer is dimethyl silicone oil.

[0068] The hydrophilic inorganic nanoparticles are inorganic nanoparticles whose surfaces are modified by hydroxyl groups, and the inorganic nanoparticles are titanium dioxide; the particle size of the hydrophilic inorganic nanoparticles is 20-40 nm.

[0069] The preparation method of the polyacrylic acid textile size includes the following steps:

[0070] (1) Mix the formula amount of polyacrylic acid, vinyl acetate, ethyl methacrylate, butyl methacrylate, emulsifier, initiator and deionized water, and react at 60°C to obtain a polyacrylate emulsion;

[0071] (2) Mix the formula amount of starch, hydroxyethyl cellulose and deionized water uniformly at...

Embodiment 3

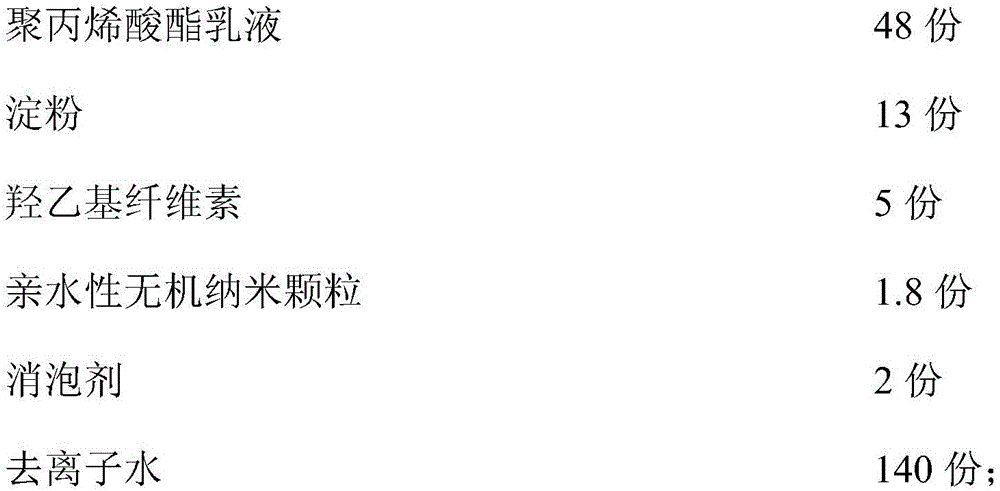

[0074] A textile slurry prepared from the following raw materials in parts by weight:

[0075]

[0076] Wherein, the polyacrylate emulsion is prepared from the following raw materials in parts by weight:

[0077]

[0078] The emulsifier is sodium lauryl sulfate and OP-10 in a volume ratio of 1:1.

[0079] The initiator is ammonium persulfate.

[0080] The defoamer is dimethyl silicone oil.

[0081] The hydrophilic inorganic nanoparticles are inorganic nanoparticles whose surfaces are modified by hydroxyl groups, and the inorganic nanoparticles are selected from silica and titanium dioxide with a weight ratio of 1:1; the particle size of the hydrophilic inorganic nanoparticles The size is 40-50nm.

[0082] The preparation method of the polyacrylic acid textile size includes the following steps:

[0083] (1) Mix the formula amount of polyacrylic acid, vinyl acetate, ethyl methacrylate, butyl methacrylate, emulsifier, initiator and deionized water, and react at 55°C to obtain a polyacrylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com