Dye sizing process with partial desizing for cowboy blending warp yarn

A denim and desizing technology, applied in the field of textile printing and dyeing, can solve the problems of insufficient drape or softness of denim, large pollution of desizing wastewater, and high cost of desizing-free sizing, so as to reduce the cost of desizing and desizing. The effect of waste water treatment cost, easy desizing process, and reduced slurry cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

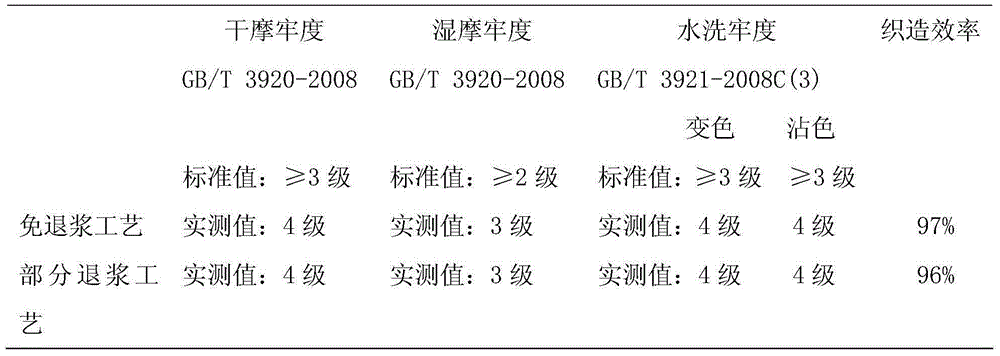

[0037] Prepare the self-crosslinking polyacrylate emulsion slurry (coating) containing blue paste FHYN (provided by Zhuhai Yuchang Chemical Co., Ltd.) according to the method of invention patent embodiment 1 of authorized publication number (CN103194917B), and the specific preparation method is:

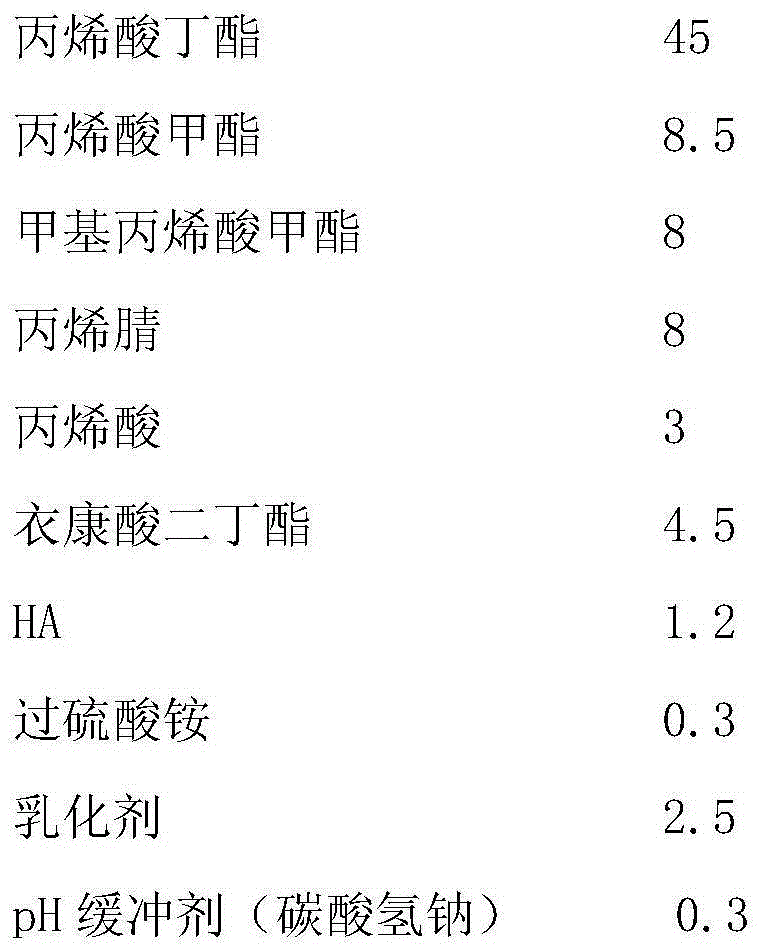

[0038] Firstly, a transparent polyacrylate emulsion slurry without colorant was prepared according to the following formula (in parts by weight).

[0039]

[0040]

[0041] Soft monomer butyl acrylate and methyl acrylate in the above-mentioned formula, hard monomer acrylic acid, methyl methacrylate and acrylonitrile, functional monomer methacrylate derivative HA, emulsifier (by weight ratio is 1: 1:2 composition of di-n-butyl sodium sulfosuccinate, disodium decyl polyoxyethylene ether sulfosuccinate and flat plus 0‐10) and 2 / 3 deionized water of the weight of the above formula are mixed at room temperature, The pre-emulsion was prepared by stirring for 20 min under the conditio...

Embodiment 2

[0057] According to the method of the above-mentioned invention patent embodiment 1 of the present application, firstly, the transparent self-crosslinking polyacrylate emulsion slurry without color paste is prepared, and then the transparent self-crosslinking polyacrylate emulsion without color paste prepared above is Add it into the stirred tank, under the condition of 300r / min medium-speed stirring, add 1 part of lubricant (0.5 parts each of GWA-L and amphoteric silicone oil DC200, Shanghai Hongtai Chemical Co., Ltd.), 6 parts of paint Color paste (yellow paste H10G provided by Zhuhai Yuchang Chemical Co., Ltd.), 0.05 parts of defoamer (TEGO-810) and 0.2 parts of thickener hydroxyethyl cellulose HEC were slowly added to the above self-crosslinking polyacrylate In the emulsion, after stirring for 0.5 hours, the material was discharged, filtered, and packaged to obtain a self-crosslinking polyacrylate emulsion slurry containing yellow slurry H10G (provided by Zhuhai Yuchang Che...

Embodiment 3

[0070] Prepare the self-crosslinking polyacrylate emulsion slurry (coating) containing the scarlet pulp TRL (provided by Zhuhai Yuchang Chemical Co., Ltd.) according to the method of invention patent embodiment 2 of the authorized publication number (CN103194917B), and the specific preparation method is:

[0071] Firstly, a transparent polyacrylate emulsion slurry without colorant was prepared according to the following formula (in parts by weight).

[0072]

[0073]Soft monomer, hard monomer, functional monomer and emulsifier in the above-mentioned formula (by weight ratio are 0.5:1:1.5 sodium di-n-butyl sulfosuccinate, decyl polyoxyethylene sulfosuccinate Disodium ester and flat plus 0‐10) and 2 / 3 of the above formula weight deionized water were mixed at room temperature and the rotation speed was 1000r / min and stirred for 20min to prepare a pre-emulsion; the initiator in the above formula was used in the formula 1 / 10 of the weight of deionized water in the reactor was di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com