Fireproof and leakproof system for high-temperature centrifugal pump

A centrifugal pump, high temperature technology, used in pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of material leakage, mechanical seal deformation, mechanical seal leakage, etc., to reduce leakage, reduce losses, and avoid accidents. the enlarged effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

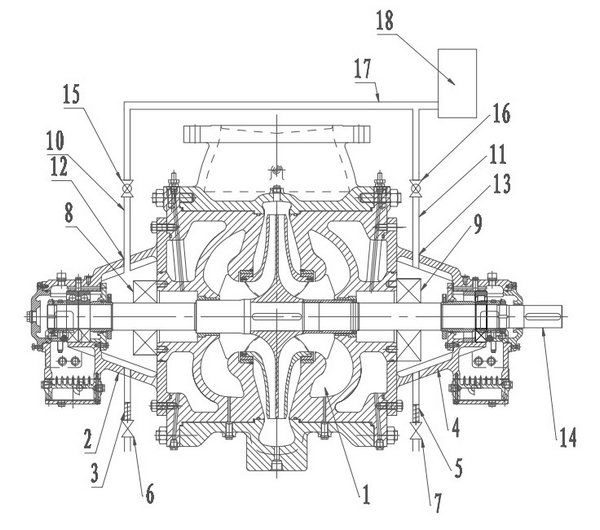

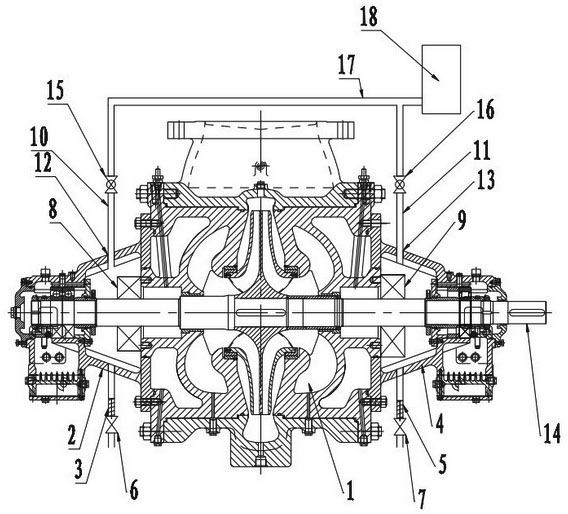

[0008] In order to gain an in-depth understanding of the fire prevention and leakage prevention system of high temperature centrifugal pumps, combined with figure 1 described as follows:

[0009] High temperature centrifugal pump fire and leakage prevention system, including pump body 1, non-drive end bearing box 2, drive end bearing box 4 and shaft 14, non-drive end bearing box 2 and drive end bearing box 4 are sealed and fixed on pump body 1 Above; the first bearing 8 is located in the closed cavity of the non-drive end bearing box 2, and the second bearing 9 is located in the closed cavity of the drive end bearing box 4; the shaft 14 passes through the first bearing 8, the pump body 1, and the second bearing 9 , and matched and fixed; the non-drive end bearing housing 2 is provided with a first air inlet 12 and a non-drive end condensation outlet 3, the first air inlet 12 is connected with the first gas pipeline 10, and the first gas pipeline 10 is provided with There is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com