Circulation multifunctional greenhouse

A greenhouse, multi-functional technology, applied in greenhouse cultivation, energy-saving measures, agricultural machinery and equipment, etc., can solve the problems of wasting coal and other energy, polluting the environment, etc., and achieve the effect of saving arable land, reducing labor intensity and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

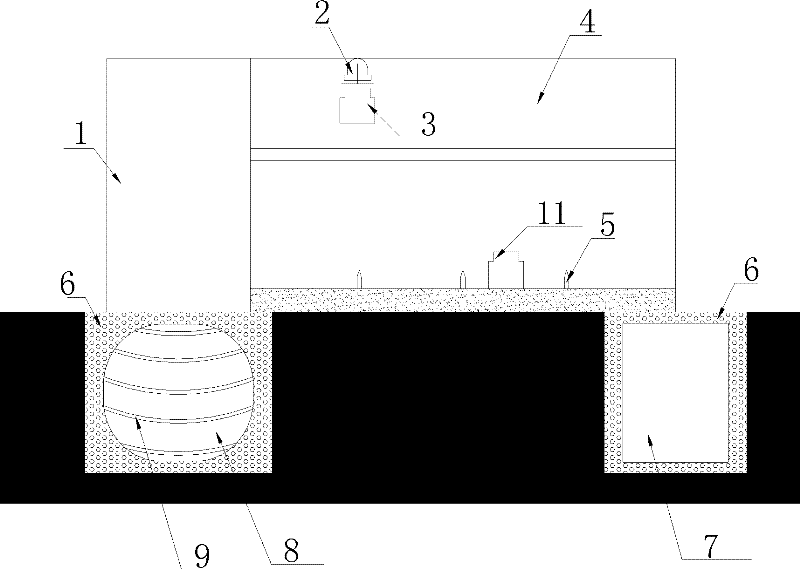

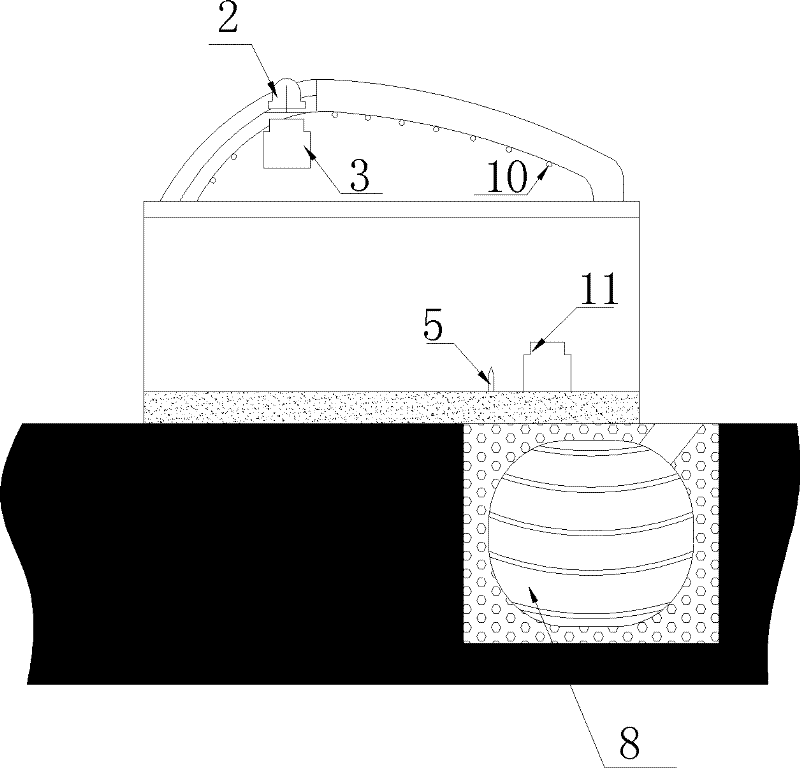

[0022] figure 1 with figure 2 It is the circular multifunctional greenhouse described in Example 1. The greenhouse includes a greenhouse body 4, and the greenhouse body 4 is divided into upper and lower layers. The upper greenhouse includes a back wall and a film support. The bottom end of the back wall is fixed on the lower greenhouse, and the top is connected with a film support. The other end of the film support extends to the front of the back wall and is fixed on the lower greenhouse. The lighting surface of the bracket is covered with a transparent plastic film, and steel brackets are provided on both sides of the back wall, and the angle between the back wall and the horizontal direction is not less than 15°. By setting a certain included angle, the area of the shaded area behind the back wall under sunlight can be reduced, thereby reducing the distance between rows of greenhouses and making full use of the planting land. Since the angle of sunlight irradiation in...

Embodiment 2

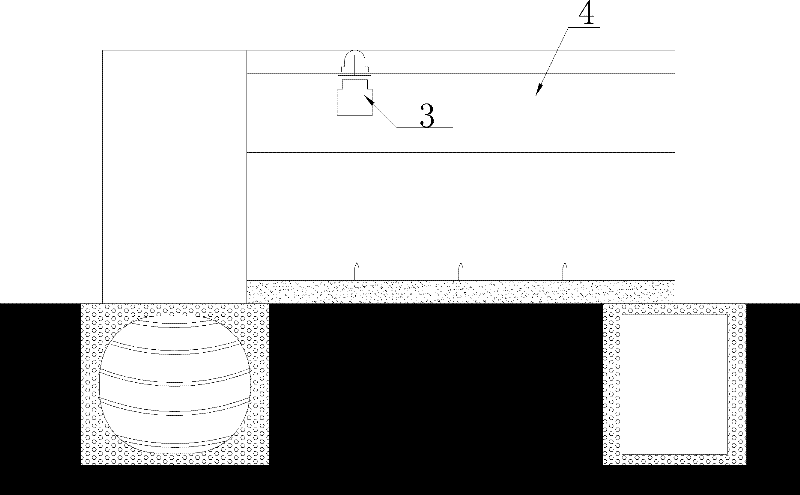

[0027] image 3 It is the circulation multifunctional greenhouse described in embodiment 2. The difference from Embodiment 1 is that the heat pump in this embodiment only includes the air source heat pump 3 , and the air source heat pump 3 is fixed on the top of the greenhouse body 4 .

[0028] Others are with embodiment 1.

Embodiment 3

[0030] Figure 4 It is the circulation multifunctional greenhouse described in embodiment 3. The difference from Embodiment 1 is that the heat pump in this embodiment only includes the water source heat pump 11, and the water source heat pump 11 is fixed in the greenhouse.

[0031] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com