Solubilizer for plant powder and application thereof

A plant and stabilizer technology, applied in the fields of application, food science, food preparation, etc., can solve the problems of waste of plant resources, low content, efficacy or functional discount, etc., and achieve the effect of easy popularization and low process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 100g of dried lotus seed powder, add 0.5% carrageenan, 0.5% lecithin, 0.5% Tween-60, add 48% water (calculated according to the mass of dried lotus seed powder), stir for 1 hour, seal and let stand for 1 hour, High pressure homogenization, homogenization pressure 35MPa, time 15min. The prepared material is dried with a vacuum drier, the drying pressure is 0.05MPa, the drying temperature is 40°C, and the drying time is 3h. The dried material is pulverized and sieved with a sieve aperture of 80 mesh to obtain the whole lotus seed powder after solubilization.

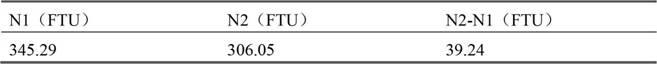

[0026] Take 5g of the prepared solubilized whole lotus seed powder, add 20ml of water, stir, dissolve, centrifuge, and dry the precipitate to constant weight. The solubilization effect is expressed by the solubilization rate (%):

[0027] Solubilization rate = (1-m / M) * 100%.

[0028] Where m and M represent the mass (g) of the precipitate after preparation and the mass (g) of the whole powder to be process...

Embodiment 2

[0034] Weigh 100g dry aloe vera powder, add 0.3% xanthan gum, 0.4% lecithin, 0.1% whey protein, 0.3% Tween-60, add 50% water (calculated according to the mass of dry aloe vera powder), stir 1h, seal and stand for 1h, high pressure homogenization, homogenization pressure 35MPa, time 15min. The prepared material was dried with a vacuum drier, the drying pressure was 0.03MPa, the drying temperature was 50°C, and the drying time was 2h. The dried material is pulverized and sieved with a sieve aperture of 80 mesh to obtain the solubilized aloe powder.

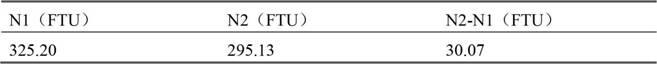

[0035] Take 5 g of the prepared solubilized aloe vera powder, add 20 ml of water, stir, dissolve and centrifuge, and dry the precipitate to constant weight. The solubilization effect is expressed by the solubilization rate (%):

[0036] Solubilization rate = (1-m / M) * 100%.

[0037] Where m and M represent the mass (g) of the precipitate after preparation and the mass (g) of the whole powder to be processed, respectively. After ...

Embodiment 3

[0043] Weigh 100g dry alfalfa powder, add 0.5% carrageenan, 0.5% lecithin, 0.5% Tween-60, 0.1% Tween-80, add 40% water (calculated according to the mass of dry alfalfa powder), stir 1h, seal and stand for 1h, high pressure homogenization, homogenization pressure 35MPa, time 15min. The prepared material is dried with a vacuum drier, the drying pressure is 0.05MPa, the drying temperature is 40°C, and the drying time is 3h. The dried material is pulverized and sieved, and the sieve aperture is 80 mesh, so as to obtain the dry alfalfa powder after solubilization.

[0044] Take 5g of the prepared dry alfalfa powder after solubilization, add 20ml of water, stir, dissolve and centrifuge, and take the precipitate and dry it to constant weight. The solubilization effect is expressed by the solubilization rate (%):

[0045] Solubilization rate = (1-m / M) * 100%.

[0046] Where m and M represent the mass (g) of the precipitate after preparation and the mass (g) of the whole powder to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com