Vibration transducer

A technology of vibrating transducer and vibrating beam, which is applied in the direction of fluid, instrument, and electromagnetic means using vibration, can solve the problems of ineffective electrostatic force and narrowing of distance, prevent mode crossing and reduce contact. area, the effect of improving vibration stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0145] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

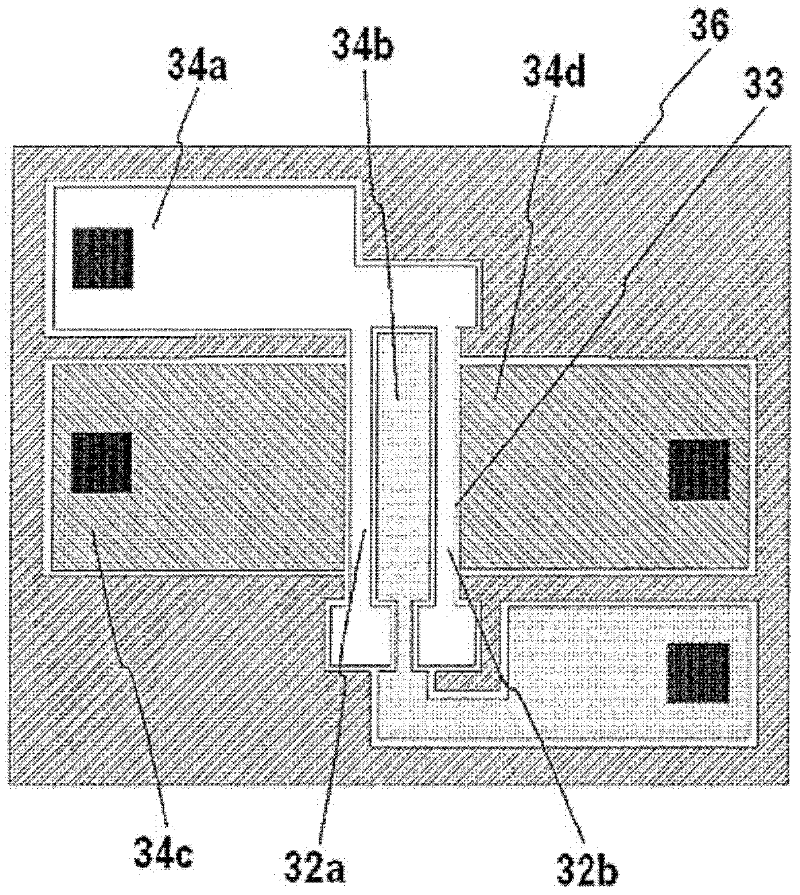

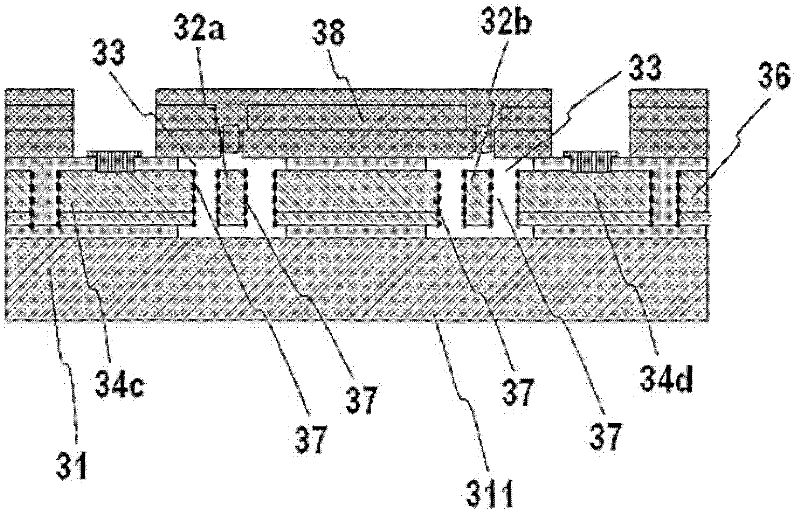

[0146] Figure 1A-1B as well as Figure 2-Figure 15 is a diagram for explaining the structure of the main part of the embodiment of the present invention.

[0147] Figure 1A-1B is a diagram for explaining the assembly structure of the main part. Figure 1A is the floor plan of the main part, Figure 1B is its cross-sectional view. Figure 1 to Figure 15 is a diagram for explaining the manufacturing process.

[0148] In the attached figure, represented by the Figure 29 Components marked with the same reference numerals have the same function accordingly.

[0149] The following only describes the Figure 29 different parts.

[0150] exist Figure 1A and Figure 1B , each of the first and second vibrating beams 32 a and 32 b is arranged in a vacuum chamber 33 . Tensile strain is applied to the substrate 31 in these vibration beams. The first and sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com