Production method of high-purity carbon oxysulfide

A carbon oxysulfide and production method technology, applied in the direction of carbon oxysulfide, carbon sulfur compounds, etc., can solve the problems of industrial production difficulties, slow reaction speed of carbon monoxide and sulfur, low yield, etc., and achieve reasonable process steps, high purity, The effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

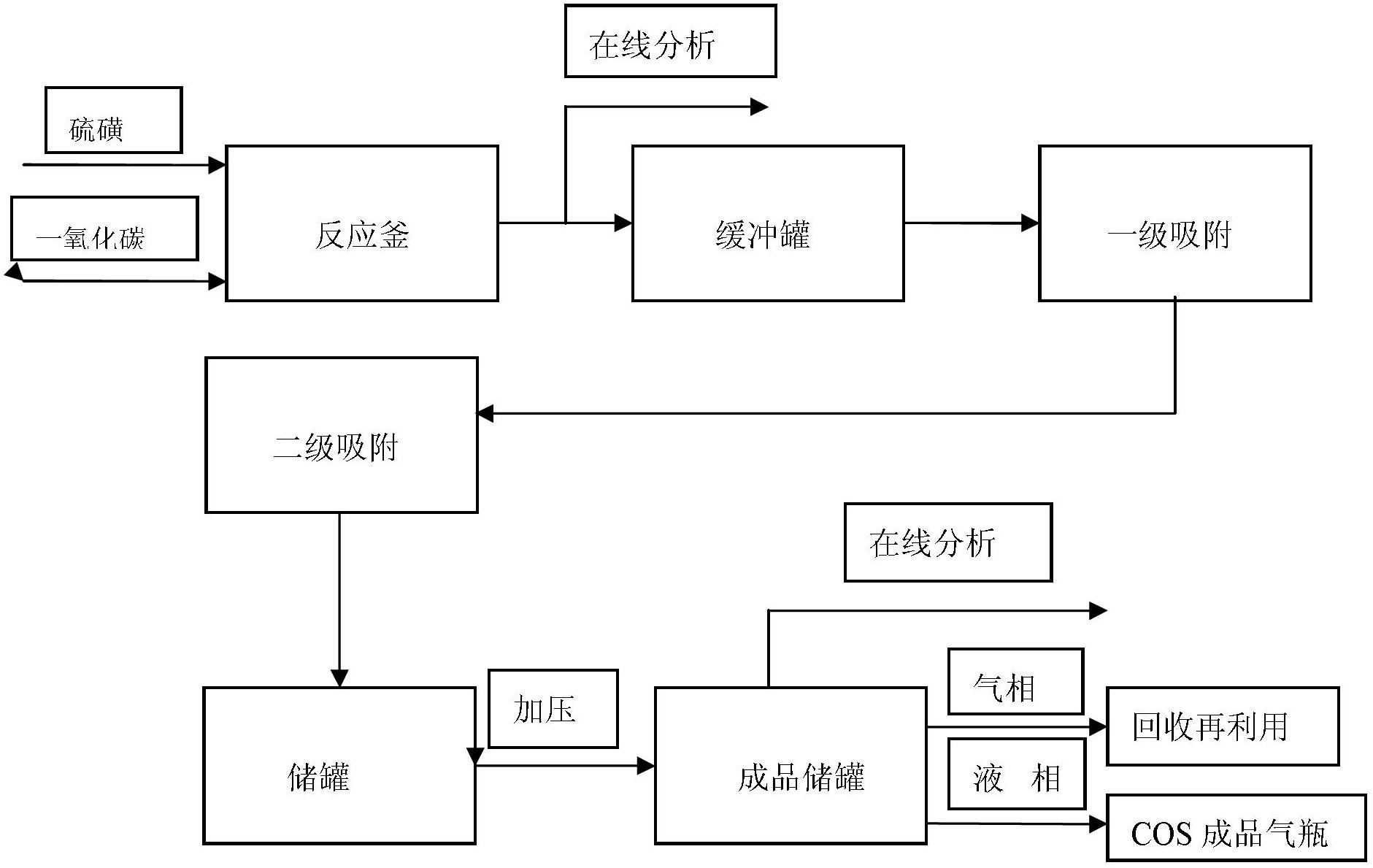

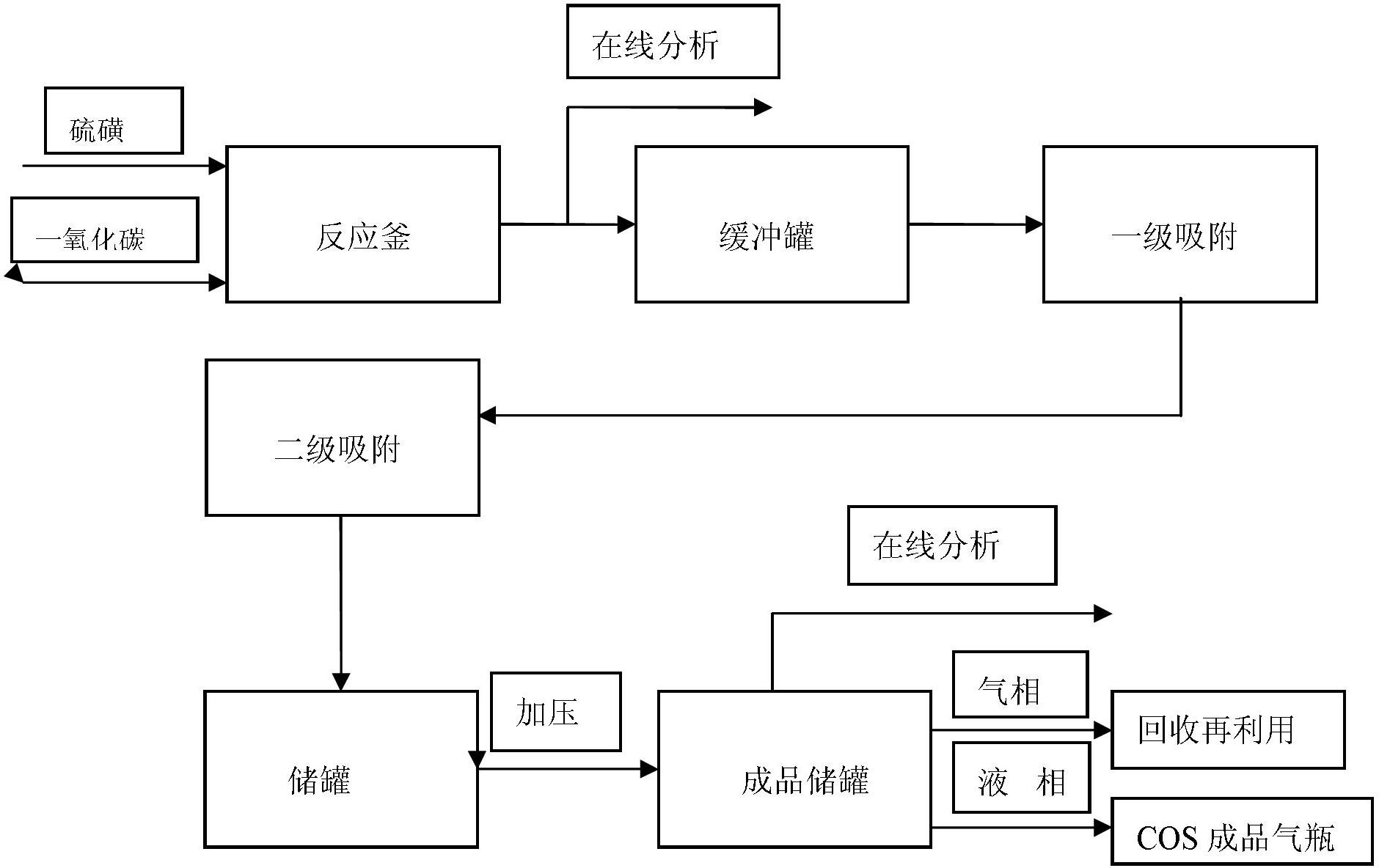

[0016] Such as figure 1 As shown, the high-purity carbon oxysulfide production method provided by the present embodiment includes the following steps carried out in order:

[0017] 1) Pass carbon monoxide gas with a purity of 99.9% into molten sulfur in a reactor at 380°C, the molar ratio of carbon monoxide to sulfur is 2:1, the flow rate of carbon monoxide is 8L / min, and the amount of catalyst is added to the sulfur at the same time Calcium chloride, carbon monoxide and sulfur react for 15S to generate carbon oxysulfide;

[0018] 2) Make the above-mentioned carbon oxysulfide flow into the buffer tank for buffering, then pass through the two-stage adsorption column successively to remove impurities and moisture such as particles, the adsorbent in the first-stage adsorption column is calcium chloride particles, and the second-stage adsorption column The adsorbent is 5A molecular sieve, which produces high-purity carbon oxysulfide, and then collects high-purity carbon oxysulfid...

Embodiment 2

[0022] Such as figure 1 As shown, the high-purity carbon oxysulfide production method provided by the present embodiment includes the following steps carried out in order:

[0023] 1) Pass carbon monoxide gas with a purity of 99.9% into molten sulfur in a reactor at 420°C, the molar ratio of carbon monoxide to sulfur is 2:1, the flow rate of carbon monoxide is 9L / min, and the amount of catalyst is added to the sulfur at the same time Calcium chloride, carbon monoxide and sulfur react 12S to generate carbon oxysulfide;

[0024] 2) Make the above-mentioned carbon oxysulfide flow into the buffer tank for buffering, then pass through the two-stage adsorption column successively to remove impurities and moisture such as particles, the adsorbent in the first-stage adsorption column is calcium chloride particles, and the second-stage adsorption column The adsorbent is 5A molecular sieve, which produces high-purity carbon oxysulfide, and then collects high-purity carbon oxysulfide in...

Embodiment 3

[0028] Such as figure 1 As shown, the high-purity carbon oxysulfide production method provided by the present embodiment includes the following steps carried out in order:

[0029] 1) Pass carbon monoxide gas with a purity of 99.9% into molten sulfur in a reactor at 450°C, the molar ratio of carbon monoxide to sulfur is 2:1, the flow rate of carbon monoxide is 10L / min, and the amount of catalyst is added to the sulfur at the same time Calcium chloride, carbon monoxide and sulfur react for 8S to generate carbon oxysulfide;

[0030] 2) Make the above-mentioned carbon oxysulfide flow into the buffer tank for buffering, then pass through the two-stage adsorption column successively to remove impurities and moisture such as particles, the adsorbent in the first-stage adsorption column is calcium chloride particles, and the second-stage adsorption column The adsorbent is 5A molecular sieve, which produces high-purity carbon oxysulfide, and then collects high-purity carbon oxysulfid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com