Method for preparing tungsten-carbide powder through low-temperature combustion synthesis

A low-temperature combustion synthesis and tungsten carbide technology, which is applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problems of tungsten carbide powder, such as no report, low output, and difficulty in industrialization, and achieve low cost and high distribution. Uniform, full contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

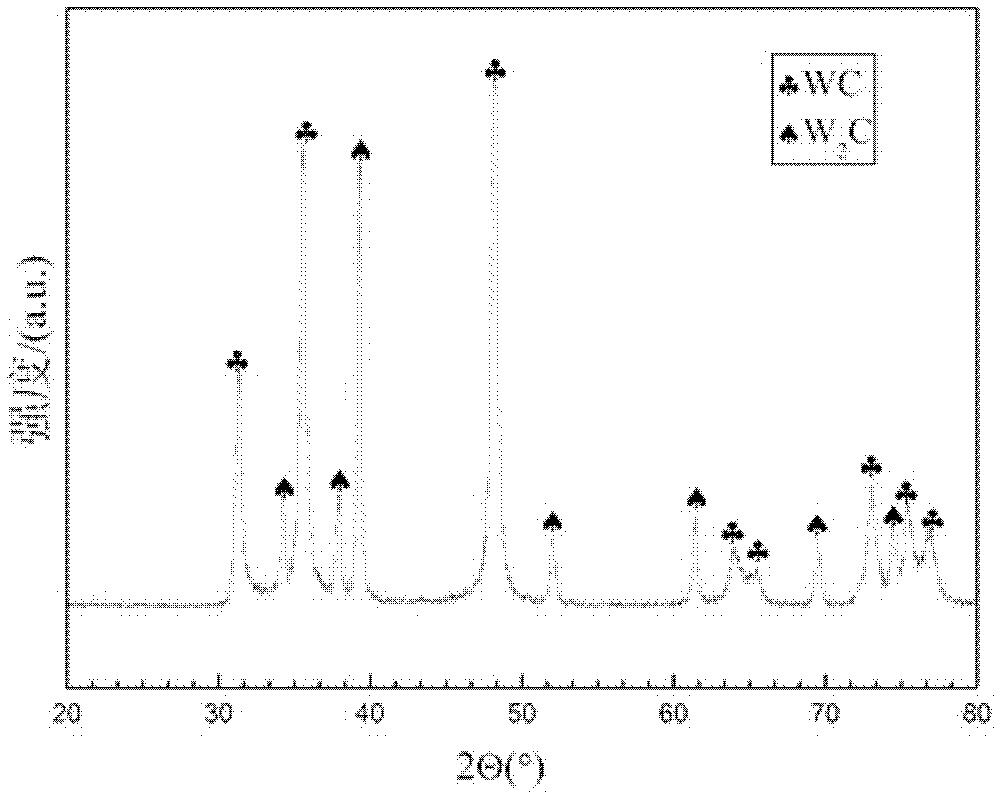

[0016] Weigh 0.015mol of ammonium tungstate, 0.1mol of urea, 0.2mol of nitric acid, and 0.2mol of glucose, add 150ml of deionized water, and mix well in a 1000ml beaker. Place the mixed solution on a closed electric furnace to heat, turn on the electric furnace to the maximum power, and stir while heating. When the water in the solution is almost evaporated to dryness and becomes viscous, stop stirring, and stop heating when the solution starts to condense, smoke and ignite automatically. After the solution was ignited, a fluffy mixture was obtained. After the mixture has cooled, take the mixture out and grind it into a powder in a mortar. The obtained powder was put into a square graphite boat, and carbonized in a resistance furnace protected by argon gas. The carbonization temperature was 900°C, and the heating rate was 3°C / min.

Embodiment 2

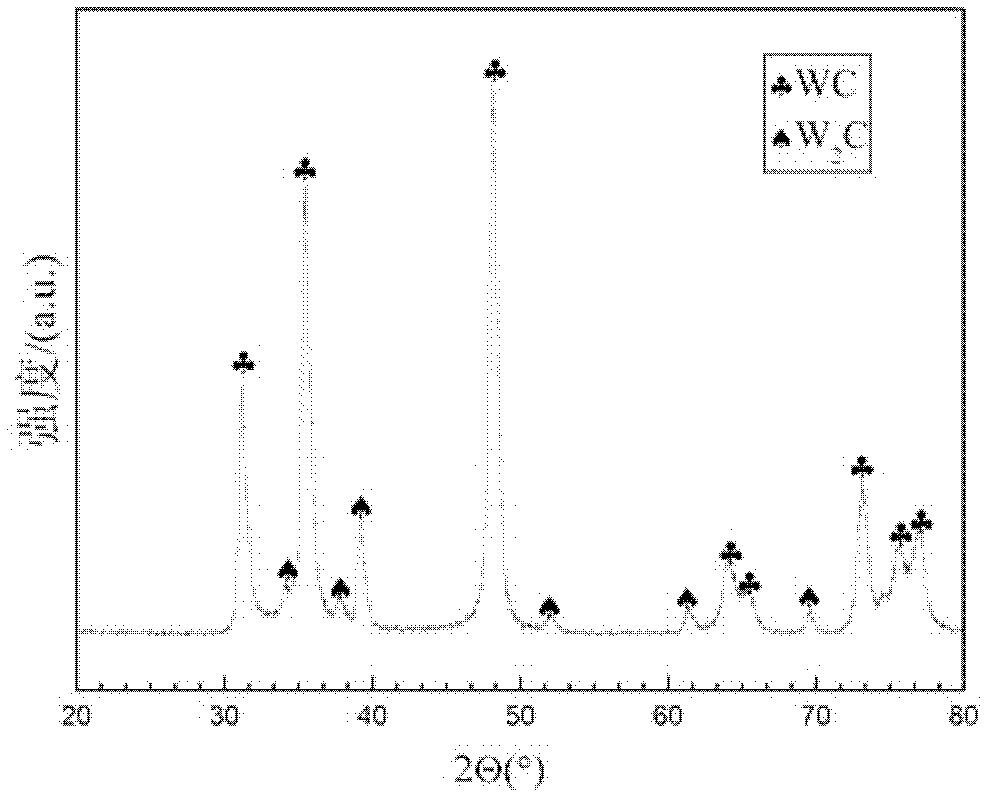

[0018] Weigh 0.015mol of ammonium tungstate, 0.1mol of urea, 0.2mol of nitric acid, and 0.2mol of glucose, add 150ml of deionized water, and mix well in a 1000ml beaker. Place the mixed solution on a closed electric furnace to heat, turn on the electric furnace to the maximum power, and stir while heating. When the water in the solution is almost evaporated to dryness and becomes viscous, stop stirring, and stop heating when the solution starts to condense, smoke and ignite automatically. After the solution was ignited, a fluffy mixture was obtained. After the mixture has cooled, take the mixture out and grind it into a powder in a mortar. The obtained powder was put into a square graphite boat, and carbonized in a resistance furnace protected by argon gas. The carbonization temperature was 1000°C, and the heating rate was 3°C / min. The minimum particle size of tungsten carbide is 1.53μm, and the average particle size is 12.11μm.

Embodiment 3

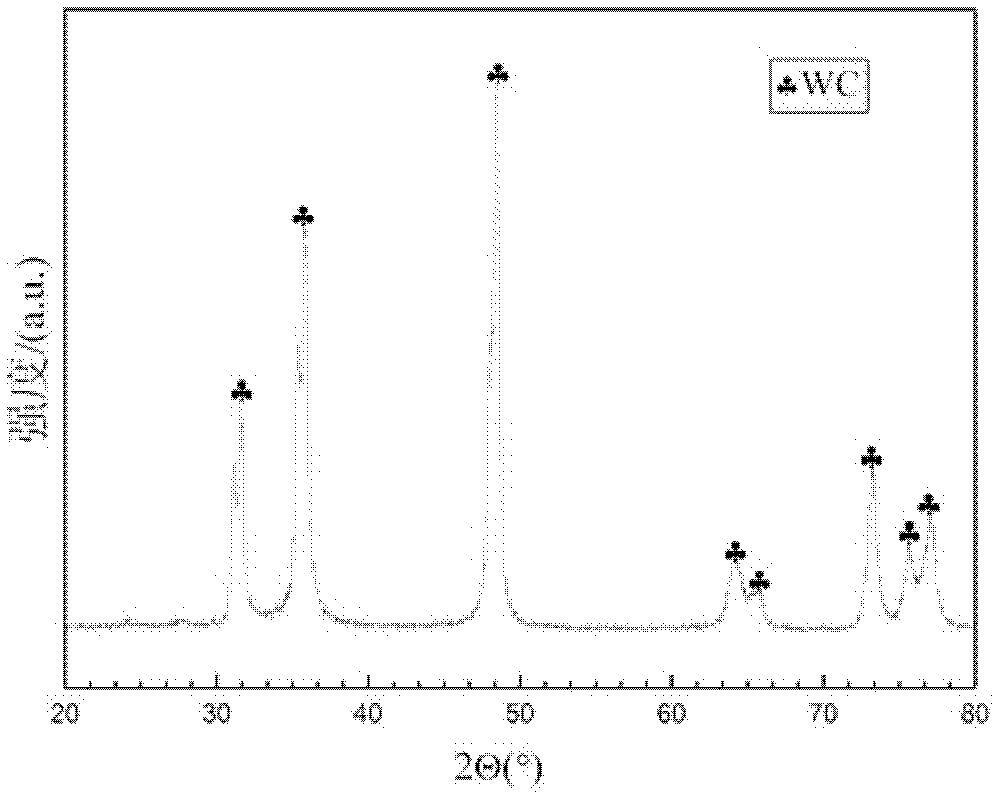

[0020] Weigh 0.015mol of ammonium tungstate, 0.1mol of urea, 0.2mol of nitric acid, and 0.2mol of glucose, add 150ml of deionized water, and mix well in a 1000ml beaker. Place the mixed solution on a closed electric furnace to heat, turn on the electric furnace to the maximum power, and stir while heating. When the water in the solution is almost evaporated to dryness and becomes viscous, stop stirring, and stop heating when the solution starts to condense, smoke and ignite automatically. After the solution was ignited, a fluffy mixture was obtained. After the mixture has cooled, take the mixture out and grind it into a powder in a mortar. The obtained powder was put into a square graphite boat, and carbonized in an argon-protected resistance furnace, the carbonization temperature was 1100°C, the heating rate was 3°C / min, and after holding for 6 hours, it was slowly cooled with the furnace to obtain tungsten carbide powder. The minimum particle size of tungsten carbide is 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com