Method for preparing cefotiam hexetil hydrochloride by cefotiam hydrochloride

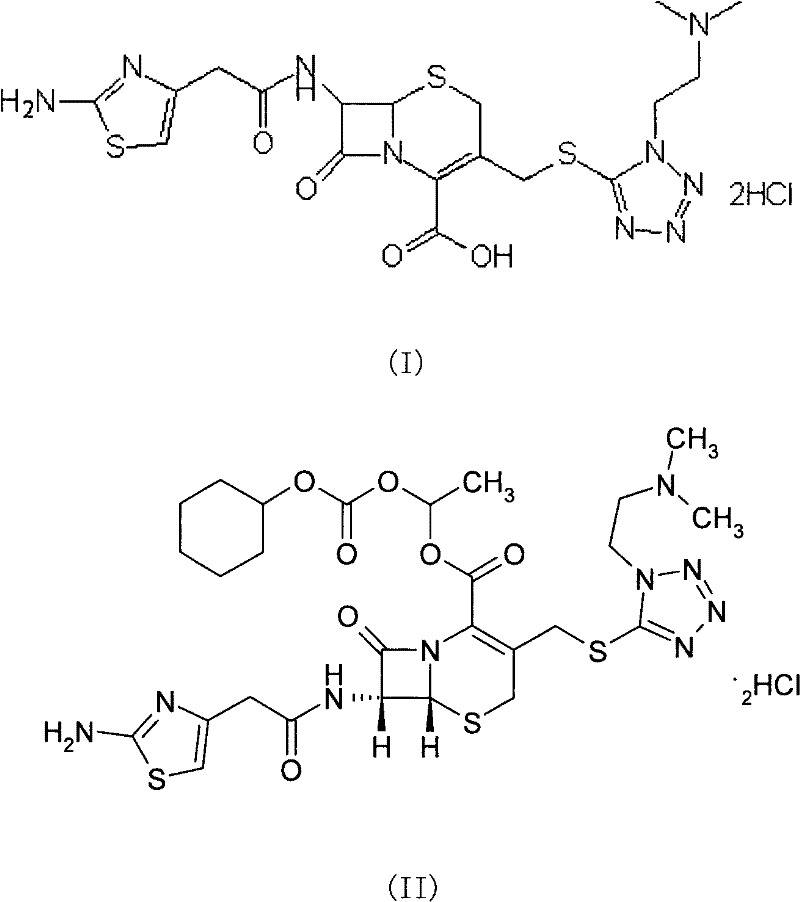

A technology of cefotiam axetil hydrochloride and cefotiam hydrochloride, which is applied in the field of medicine, can solve the problems of low yield of cefotiam axetil hydrochloride, low yield of cefotiam salt, unfavorable impurity removal treatment, etc., and achieve High pollution, high purity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

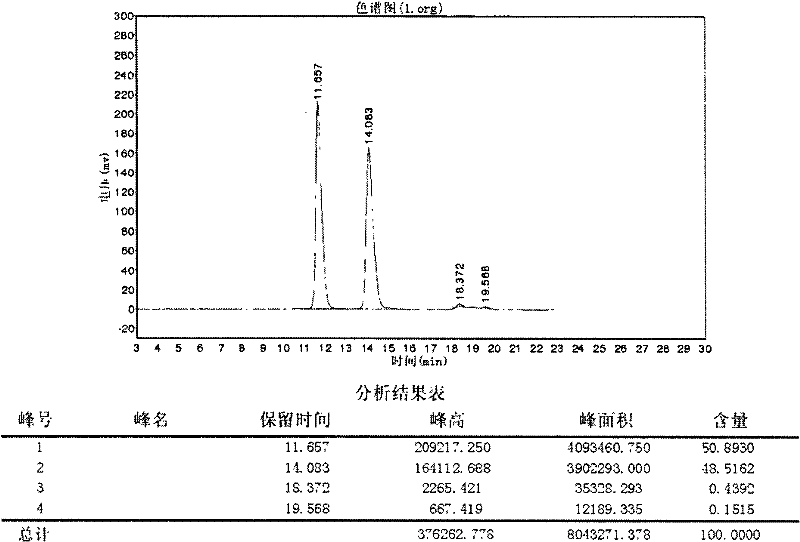

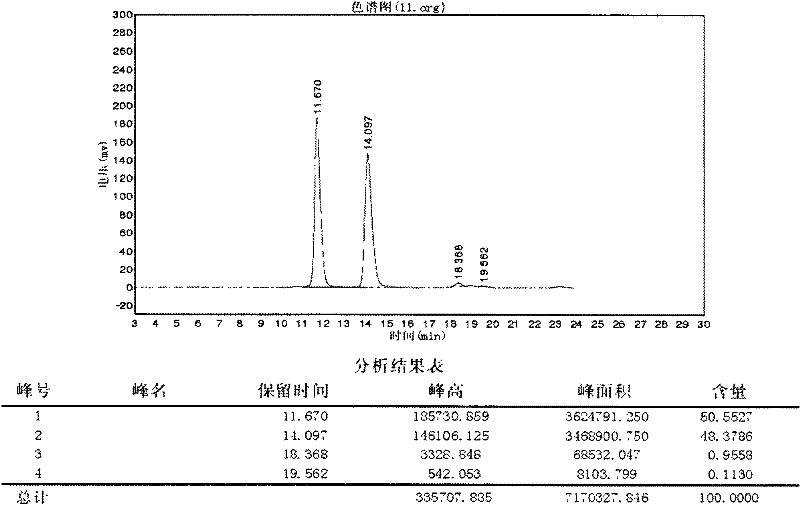

Examples

Embodiment 1

[0038] Embodiment 1: a kind of preparation method of cefotiam hydrochloride comprises following preparation steps:

[0039] ① Add 60ml of water to 100g of KHCO3, stir quickly, and slowly add 120g of cefotiam hydrochloride at 25-30°C, after adding, continue to keep stirring at 25-30°C for 30 minutes. React under reduced pressure for 30-40 minutes, then add 25 times the amount of acetone (water) to the reaction system, lower the temperature to 0°C within 30 minutes, stop stirring, stand still for more than 30 minutes, and transfer The supernatant was obtained as cefotiam potassium salt.

[0040]②Add 550ml of N,N-dimethylformamide preheated to 30-40°C to cefotiam potassium salt, and stir the mixed system under reduced pressure below 30°C for 1 hour to dissolve the potassium salt. After dissolving, cool down to - 15~-20°C, add 1-iodide ethyl cyclohexyl carbonate which is pre-cooled to below -15°C into the reaction system, control the temperature at -15~-20°C and stir for 30 minut...

Embodiment 2

[0047] Embodiment 2: a kind of preparation method of cefotiam hydrochloride comprises following preparation steps:

[0048] ①Add 30ml of water and 60ml of acetone to 380g of NaHCO, stir rapidly, slowly add 100g of cefotiam hydrochloride at 25-30°C, react under reduced pressure for 30-40 minutes, then add fifty times (water ) amount of acetone, the temperature was lowered to 0~-5°C within 30 minutes, the agitation was stopped, the stratification was static for more than 30 minutes, and the supernatant was removed to obtain cefotiam sodium salt.

[0049] ②Add 500ml of N,N-dimethylacetamide preheated to 30-35°C to cefotiam sodium salt, and stir the mixed system under reduced pressure below 35°C for 1.5 hours to dissolve the sodium salt, then cool down to - 15~-20℃, add 1-iodide ethyl cyclohexyl carbonate which has been pre-cooled to below -15℃ into the reaction system, control the temperature at -5~-10℃ and stir for 25 minutes, then add and cool down to 2℃ The following 3500ml o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com