Ultrasonic low frequency-high frequency coupled atomization biological reaction device

A biological reaction device, high-frequency coupling technology, applied in the direction of biochemical cleaning device, enzymology/microbiology device, bioreactor/fermenter combination, etc. It can solve the problems of large amount and difficult to enlarge the atomization reactor, so as to achieve the effect of being beneficial to growth and metabolism, easy to operate, and to eliminate the phenomenon of attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The reaction device of the present invention will be further described below according to specific examples.

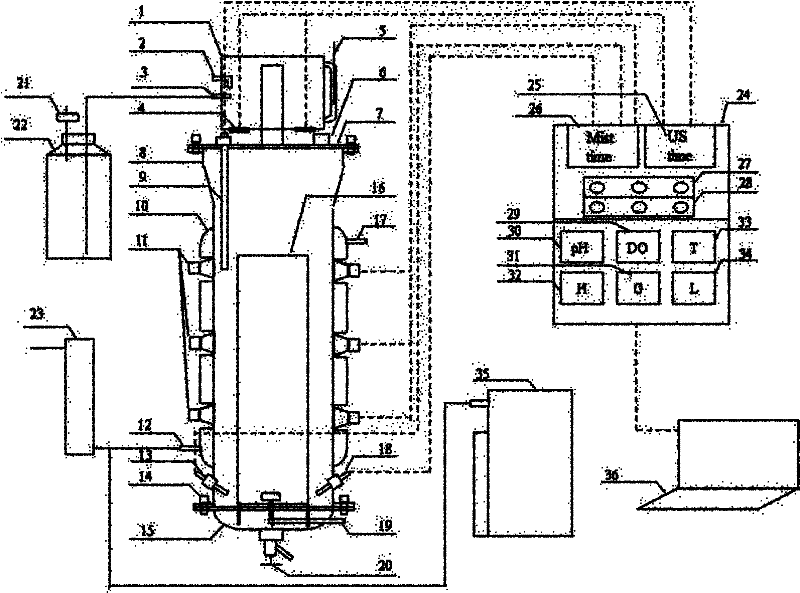

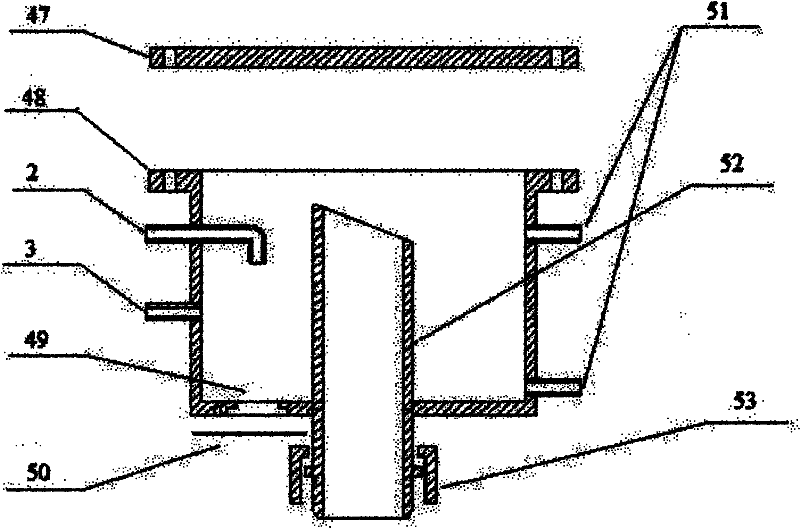

[0056] like figure 1 As shown, the ultrasonic low-frequency-high-frequency coupled atomization bioreactor device of the present invention includes a reactor tank system, a high-frequency ultrasonic atomization system, a low-frequency ultrasonic system and an inoculation device, wherein the reactor tank system includes Flange 7, reactor tank body 8, electrode 9, reactor temperature control jacket 10, detachable guide tube 16, lower flange 15 and jacketed water heater 23; wherein the reactor upper flange 7, lower method The flange 15 is sealed and connected with the reactor tank 8 through the flange fixing bolt 14; the electrode 9 measures the dissolved oxygen and pH index in the reactor tank 8, and realizes reactor Monitoring of internal dissolved oxygen and pH value; the humidity sensing probe 13 is hermetically connected with the reactor tank 8 for measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com