Method for preparing high-purity galacto-oligosaccharide by continuous simulated moving bed chromatography separation

A galacto-oligosaccharide and simulated moving bed technology, which is applied in the field of functional sugar preparation, can solve the problems of low purity and achieve high separation efficiency, extensive health care and medicinal value, and good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

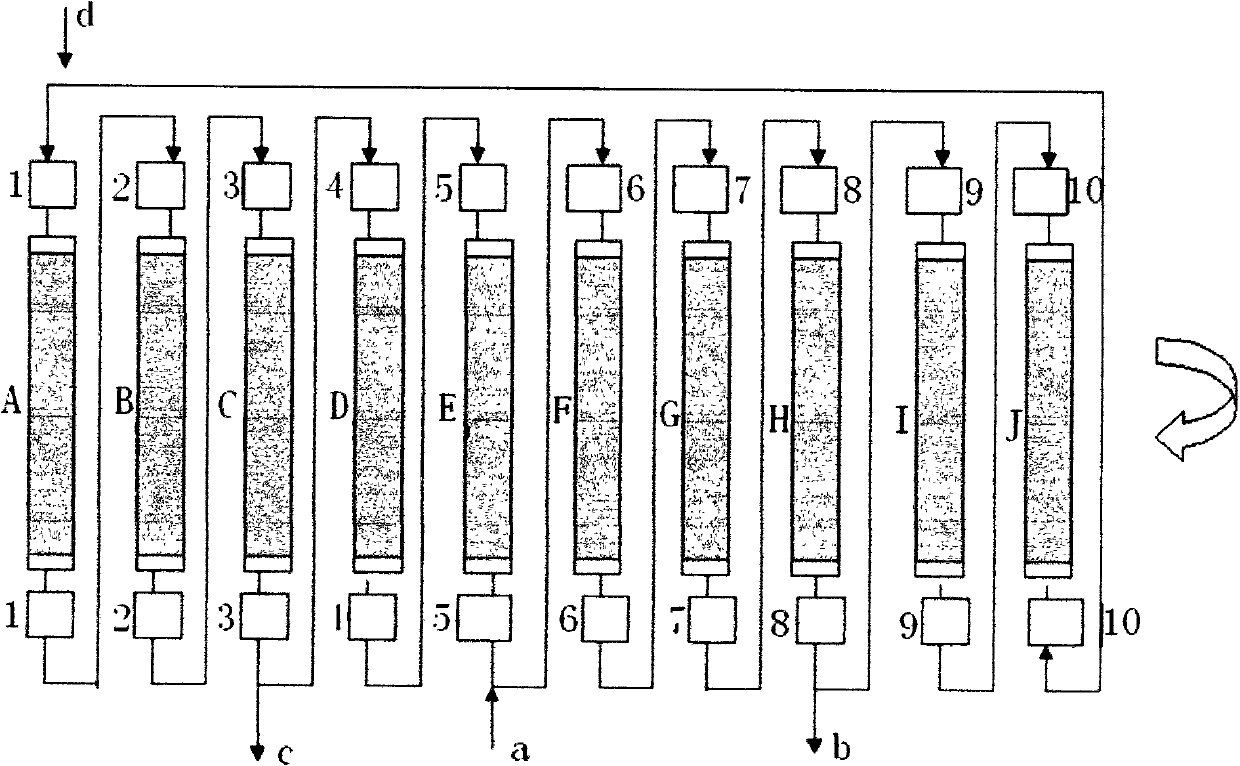

Method used

Image

Examples

Embodiment 1

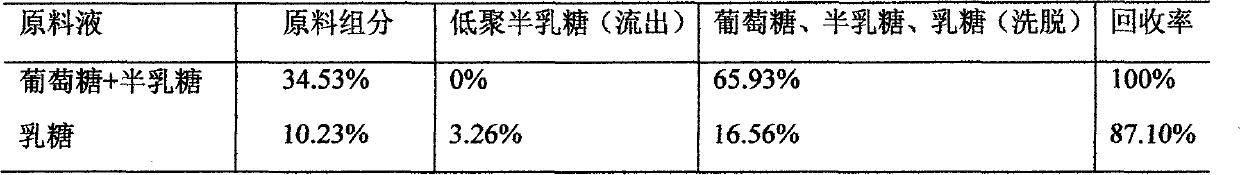

[0030] Strain BLB-21 was inoculated with the seed solution with a glucose concentration of 300g / L for expansion. The secondary seed solution (concentration: 0.52% of the wet weight of mycelium) was added to 20% lactose solution in an amount of 10% (V / V) for fermentation, adjusted to pH 5.5, and fermented at 25-30° C. for 40 hours. The mixture of sugar components was preliminarily obtained by ultrafiltration. After decolorization by activated carbon, strong acidic cations-weak basic anions-strong acidic cation exchange resins were used for separation and desalination at a temperature of 30-35°C, an injection volume of 10L / h, and a resin height of 1m. A sugar solution with a galacto-oligosaccharide content of 55.24% was detected by HPLC. At this time, the sugar components are glucose, galactose, lactose, and galactooligosaccharides.

[0031] The chromatographic separation parameters are: the filling height of the resin column is 0.65m, the rotating speed of the distribution pla...

Embodiment 2

[0036] Strain BLB-21 was inoculated with the seed solution with a glucose concentration of 400g / L for expansion. The secondary seed solution (concentration: 0.45% of the wet weight of mycelium) was added to 30% lactose solution in an amount of 10% (V / V) for fermentation, adjusted to pH 5.5, and fermented at 30-35° C. for 30 hours. The mixture of sugar components was preliminarily obtained by ultrafiltration. After decolorization by activated carbon, strong acidic cation-weak basic anion-strong acidic cation exchange resin was used for separation and desalination at a temperature of 35-40°C, an injection volume of 10L / h, and a resin height of 1m. A sugar solution with a galacto-oligosaccharide content of 56.54% was detected by HPLC. At this time, the sugar components are glucose, galactose, lactose, and galactooligosaccharides.

[0037] The parameters are: the filling height of the resin column is 0.65m, the rotation speed of the distribution plate is 3° / min, the feed concentr...

Embodiment 3

[0041]The strain BLB-21 was inoculated with the seed solution with a glucose concentration of 500g / L for expansion. The secondary seed solution (concentration: 0.56% of the wet weight of mycelia) was added to 40% lactose solution in an amount of 10% (V / V) for fermentation, adjusted to pH 5.5, and fermented at 35-40° C. for 20 hours. The mixture of sugar components was preliminarily obtained by ultrafiltration. After decolorization by activated carbon, strong acidic cation-weak basic anion-strong acidic cation exchange resin was used for separation and desalination at a temperature of 45-50°C, an injection volume of 10L / h, and a resin height of 1m. A sugar solution with a galacto-oligosaccharide content of 55.72% was detected by HPLC. At this time, the sugar components are glucose, galactose, lactose, and galactooligosaccharides.

[0042] The parameters are: the filling height of the resin column is 0.65m, the rotation speed of the distribution plate is 3° / min, the feed concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com