Method for electrolyzing and regenerating alkaline etching liquid

A technology of electrolytic regeneration and etching solution, which is applied in the field of electrolytic regeneration of alkaline etching waste liquid used for etching printed circuit boards, can solve the problems of reducing copper ion concentration, low current efficiency, and non-recyclable substances, etc., to reduce production cost, increase production efficiency, and save electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

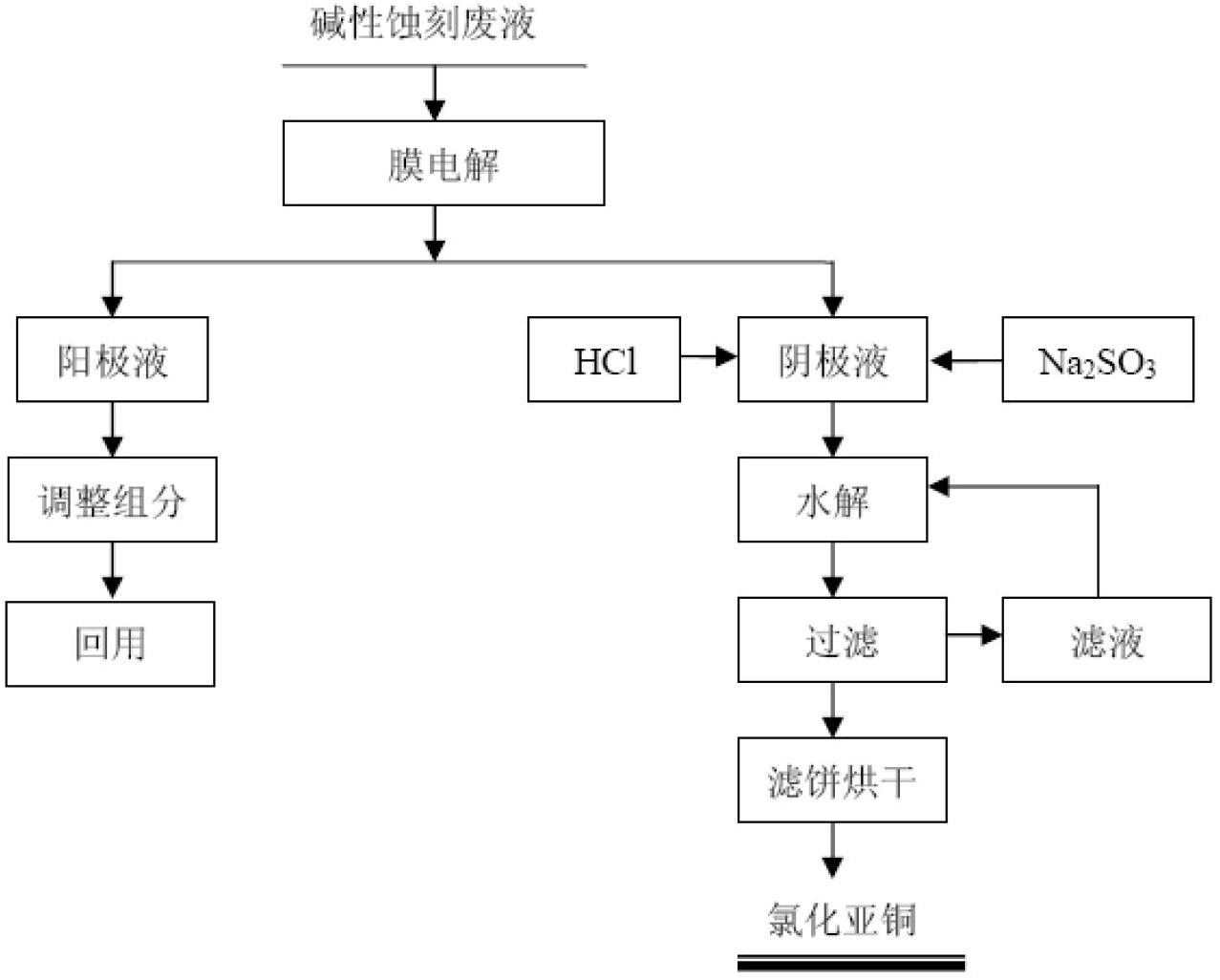

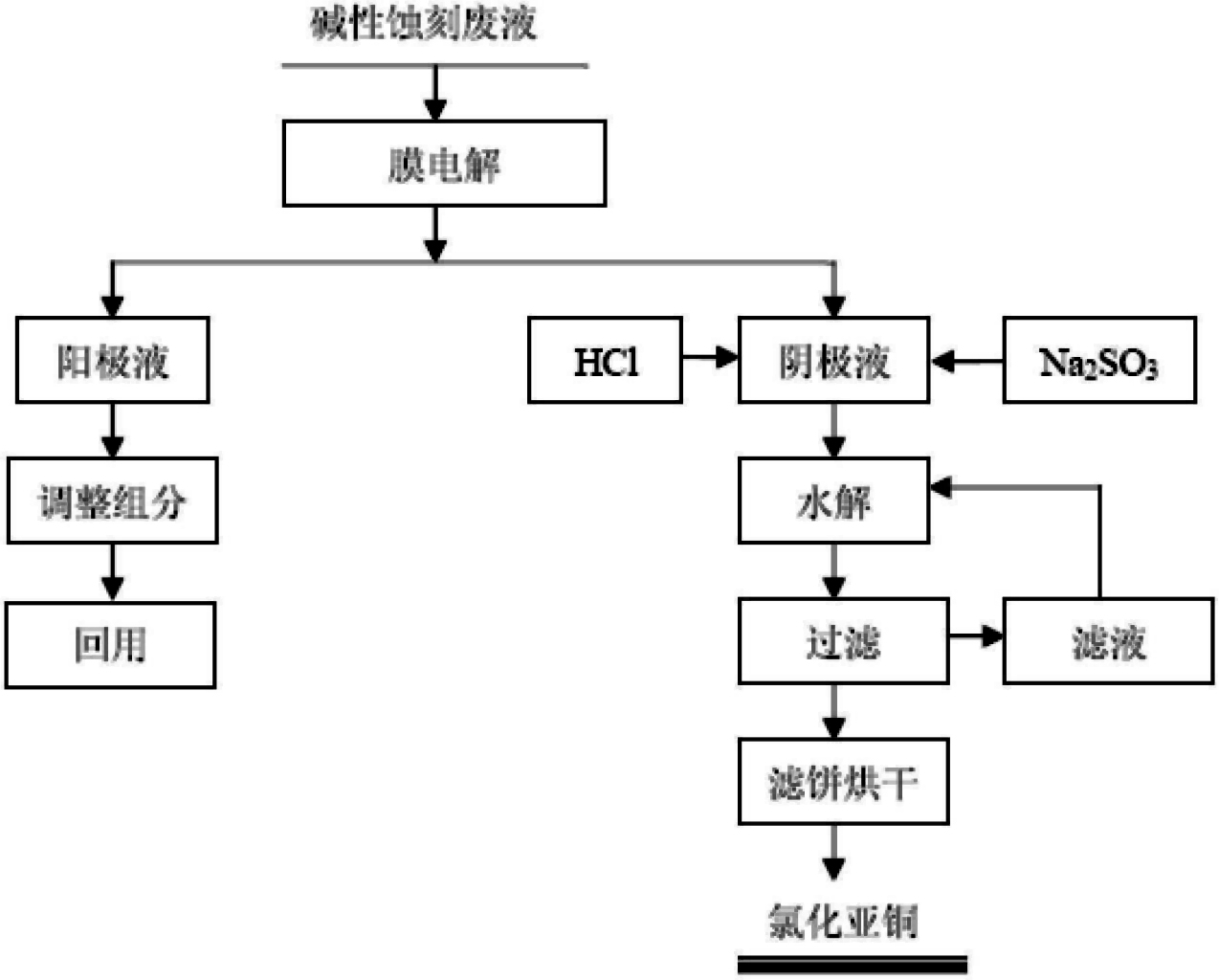

[0048] The preparation contains 140g / L of total copper, 160g / L of chloride ions, pH of 8.8, and specific gravity of 1.180g / cm 3 Alkaline etching solution for etching machine work. When etching is in progress, the alkaline etching solution passes through the etching machine to produce etching waste liquid. The total copper of the waste liquid is 160g / L, the chloride ion is 180g / L, the pH is 8.1, and the specific gravity is 1.215g / cm 3 .

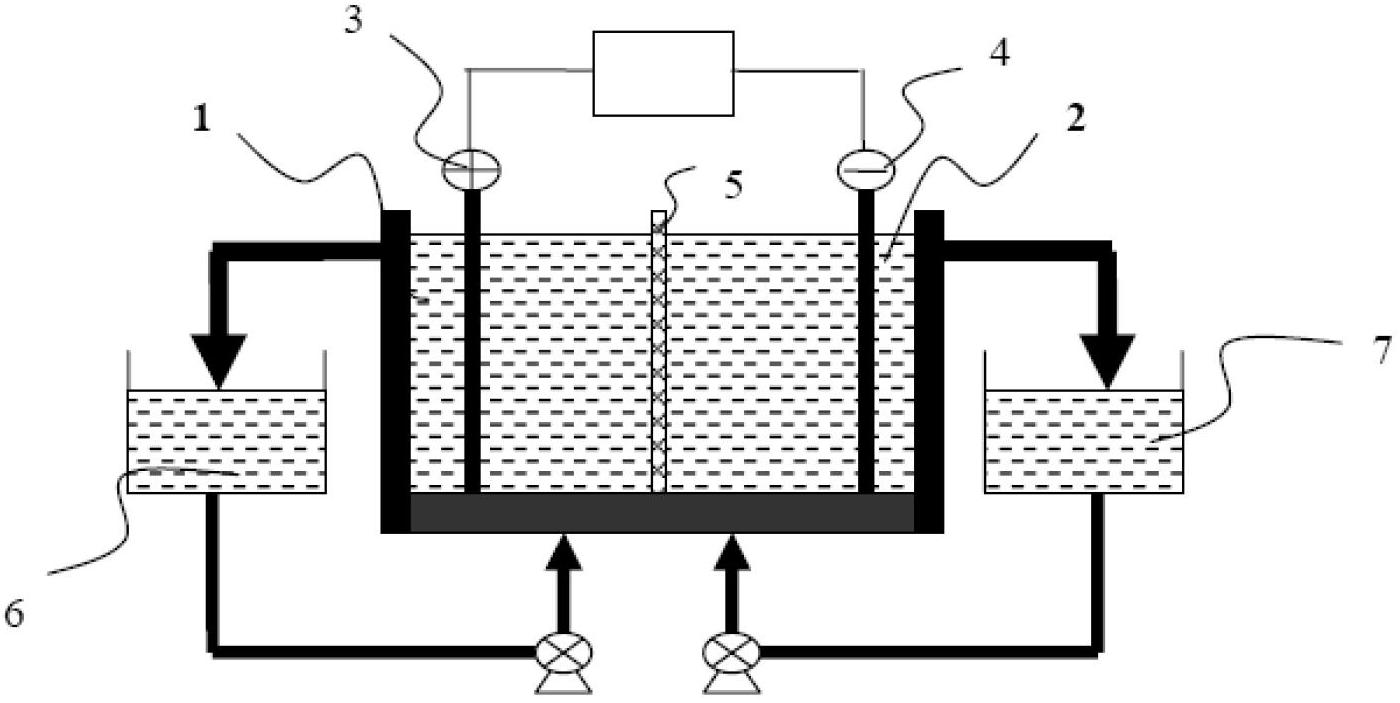

[0049] The etching waste liquid is injected into the anode liquid storage tank 6 and the cathode liquid storage tank 7, and is respectively input into the anode chamber 1 and the cathode chamber 2 through the corrosion-resistant pump for electrolysis. During the electrolysis, the electrolyte in the anode chamber 1 is kept in the Circulating flow in the anode chamber 1 and the anode liquid storage tank 6 makes the electrolyte in the cathode chamber 2 circulate in the cathode chamber 2 and the cathode liquid storage tank 6, and the electrolysis...

Embodiment 2

[0053] The preparation contains 140g / L of total copper, 24% of ammonium chloride, 10% of ammonia water, pH of 8.8, and specific gravity of 1.17g / cm 3 Alkaline etching solution for etching machine work. When the etching is in progress, the alkaline etching solution passes through the etching machine to produce etching waste liquid, the total copper is 150g / L, the chloride ion is 205g / L, the pH is 8.4, and the specific gravity is 1.203g / cm 3 .

[0054] The etching waste liquid is injected into the anode liquid storage tank 6 and the cathode liquid storage tank 7, and is respectively input into the anode chamber 1 and the cathode chamber 2 through the corrosion-resistant pump for electrolysis. During the electrolysis, the electrolyte in the anode chamber 1 is kept in the The circulation flow in the anode chamber 1 and the anode liquid storage tank 6 makes the electrolyte in the cathode chamber 2 circulate in the cathode chamber 2 and the cathode liquid storage tank 6, and an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com