Controllable temperature phase-change induction fiber and preparation method thereof

A phase change and fiber technology, applied in fiber treatment, spinning solution preparation, cellulose/protein conjugated artificial filament, etc., can solve the problem of poor temperature regulation performance and temperature regulation effect, uneven dispersion of phase change materials, breathability In order to achieve the effects of small phase change volume change, high phase change latent heat, and high air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Preparation of silk fibroin film

[0015] (1) Degumming of silk

[0016] Weigh a certain amount of mulberry silk, degumming with 0.5‰ (w / w) sodium carbonate solution, the liquor ratio (mass ratio of silk fibroin to solution) is 1:20, boil in boiling water for 30min, and then wash with deionized water , so repeated 3 times to remove sericin on the surface of silk fibroin to obtain pure silk fibroin. The pure silk fibroin after degumming is placed in an oven, baked at a constant temperature of 100°C for 4 hours, and set aside.

[0017] (2) Dissolution of SF

[0018] The degummed mulberry silk was dissolved in LiBr:C 2 h 5 In OH=40:60(w / w) solution, the bath ratio is 1:5, placed in a water bath at (80±2)℃ and stirred at constant temperature until it is completely dissolved to obtain the SF solution.

[0019] (3) Dialysis of SF solution

[0020] Inject the cooled SF solution into a dialysis bag of 8,000 to 14,000 Daltons, seal both ends, run dialysis with tap water...

Embodiment 2

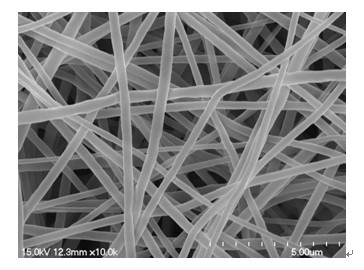

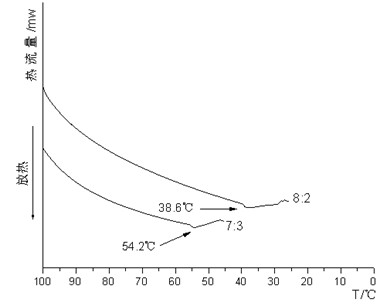

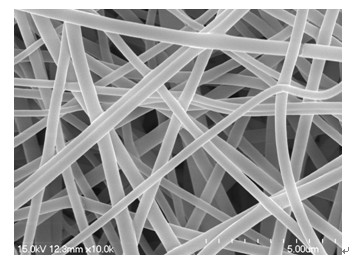

[0027] By the regenerated SF membrane that makes by embodiment 1 and molecular weight 4000 PEG was mixed at a ratio of 8:2 and 7:3 (w / w) respectively and put into the HFIP solution, sealed and placed in a constant temperature water bath shaker (water temperature 25°C), dissolved for 5 days, and a total of SF / PEG with different ratios was obtained. Mixed liquid. After filtering through a stainless steel filter and vacuum defoaming, a pure blended spinning solution with a content of 16% (w / w) was obtained. Pour the SF / PEG mixed solution produced above into the syringe, adjust the distance between the syringe needle and the liquid coagulation collection bath to be 12cm, the voltage of the high-voltage power supply to be 7kv, and the advance speed of the syringe to be 0.40ml / h. The spinning solution forms a jet under the process parameters, and the jet is drawn, and after the solvent is volatilized, a micro-nano fiber mat similar to a non-woven fabric is finally formed in the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com