Burner for biomass fuel

A biomass fuel and burner technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve problems such as the inability to effectively solve the slagging problem, achieve combustion efficiency, solve the slagging problem, and improve combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

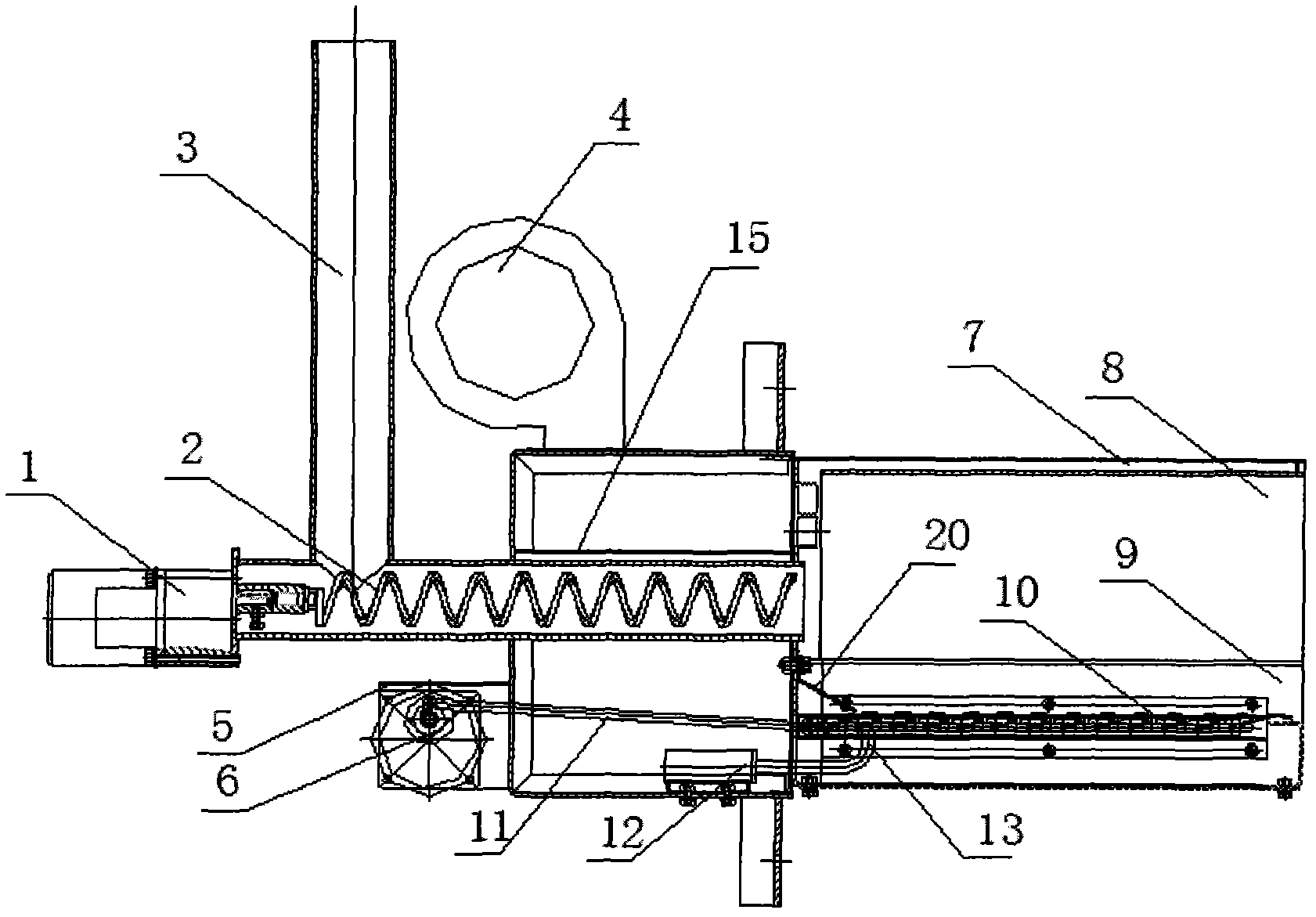

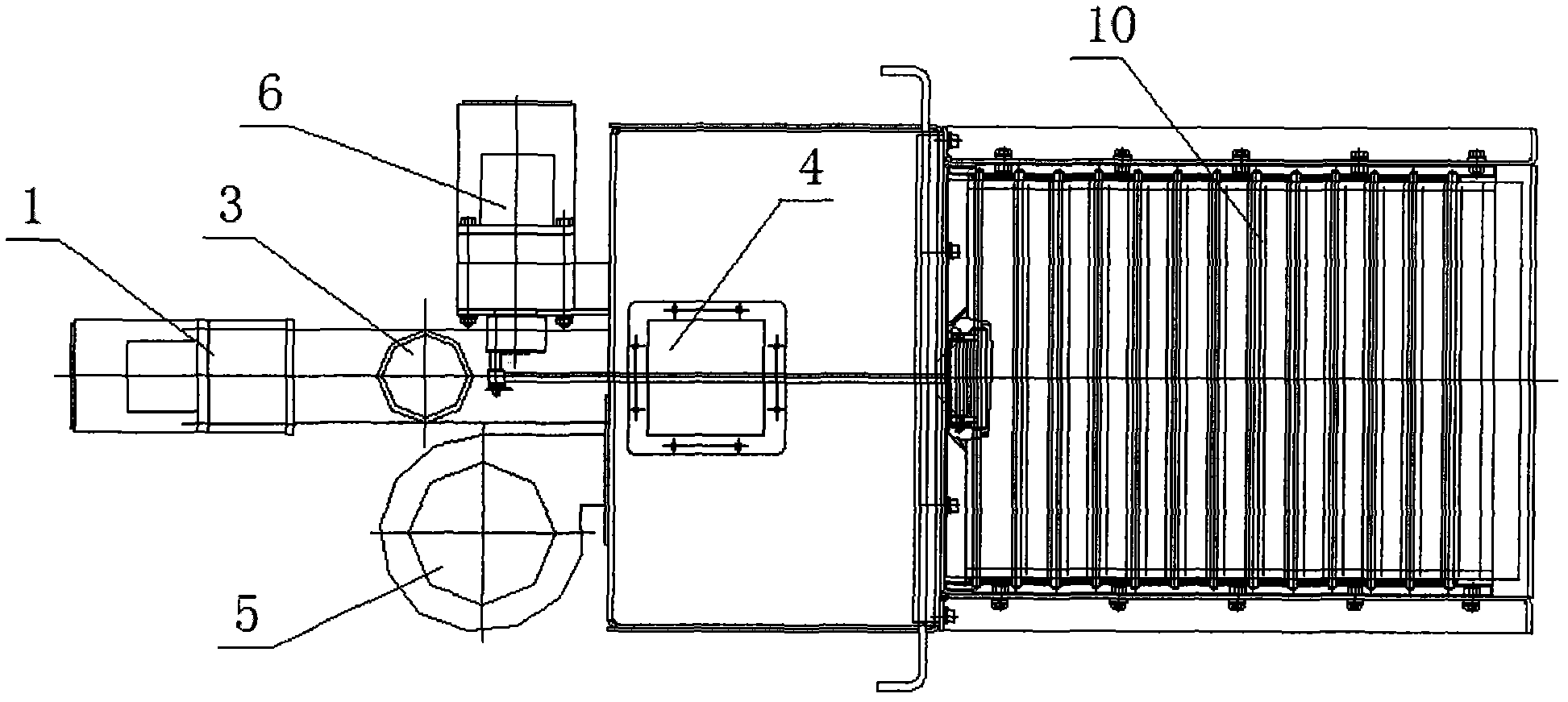

[0047] Example: Application of Greenhouse Biomass Fuel Burner

[0048] The biomass fuel burner designed and manufactured by the present invention has a power of 350KW and an internal combustion chamber diameter of 50cm. The invention is applied to a facility greenhouse in Daxing, Beijing, which covers an area of 3000 square meters. The biomass fuel burner of this invention is installed in a 350KW biomass boiler, and is equipped with a silo, a feeding mechanism, etc., to realize automatic feeding, automatic ignition, automatic control, etc., and provide heating and hot water for the greenhouse ,Such as Figure 13 shown.

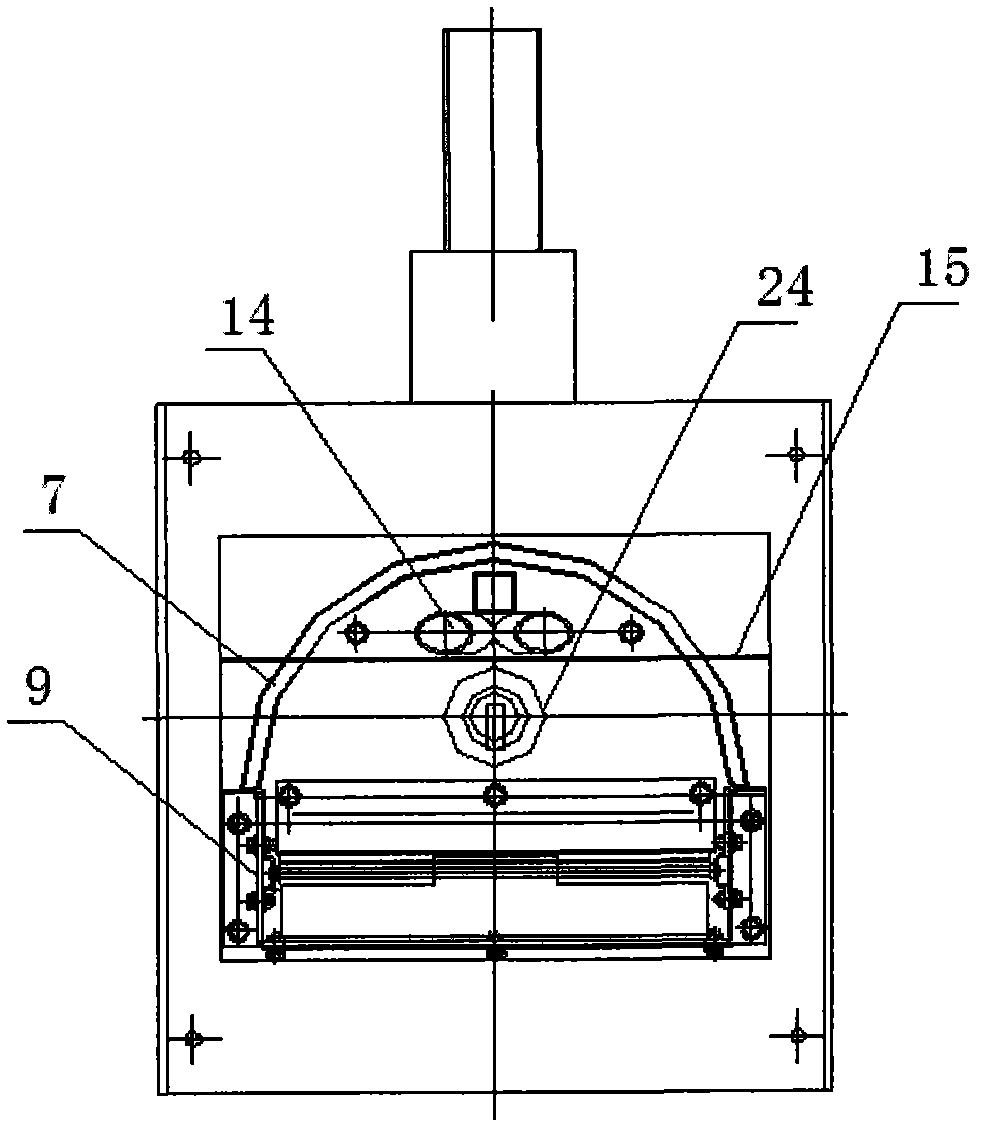

[0049] The biomass fuel burner of the present invention is installed in the biomass boiler. When working, the biomass solid shaped fuel entering the feeding cylinder 3 is propelled into the inner combustion chamber 8 through the feeding screw 2, and the slag cleaning motor 6 passes through the crank 11 provides power for the slag removal device 10, the pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bend angle | aaaaa | aaaaa |

| Bend angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com