Tanshinone microemulsion and preparation method thereof

A technology of tanshinone and microemulsion, which is applied in the field of carrier systems in cosmetics technology, can solve the problems of poor water solubility, inability to directly apply cosmetics, and low tanshinone content, and achieve the effects of good stability, convenient preparation, and high content of active substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 tanshinone microemulsion

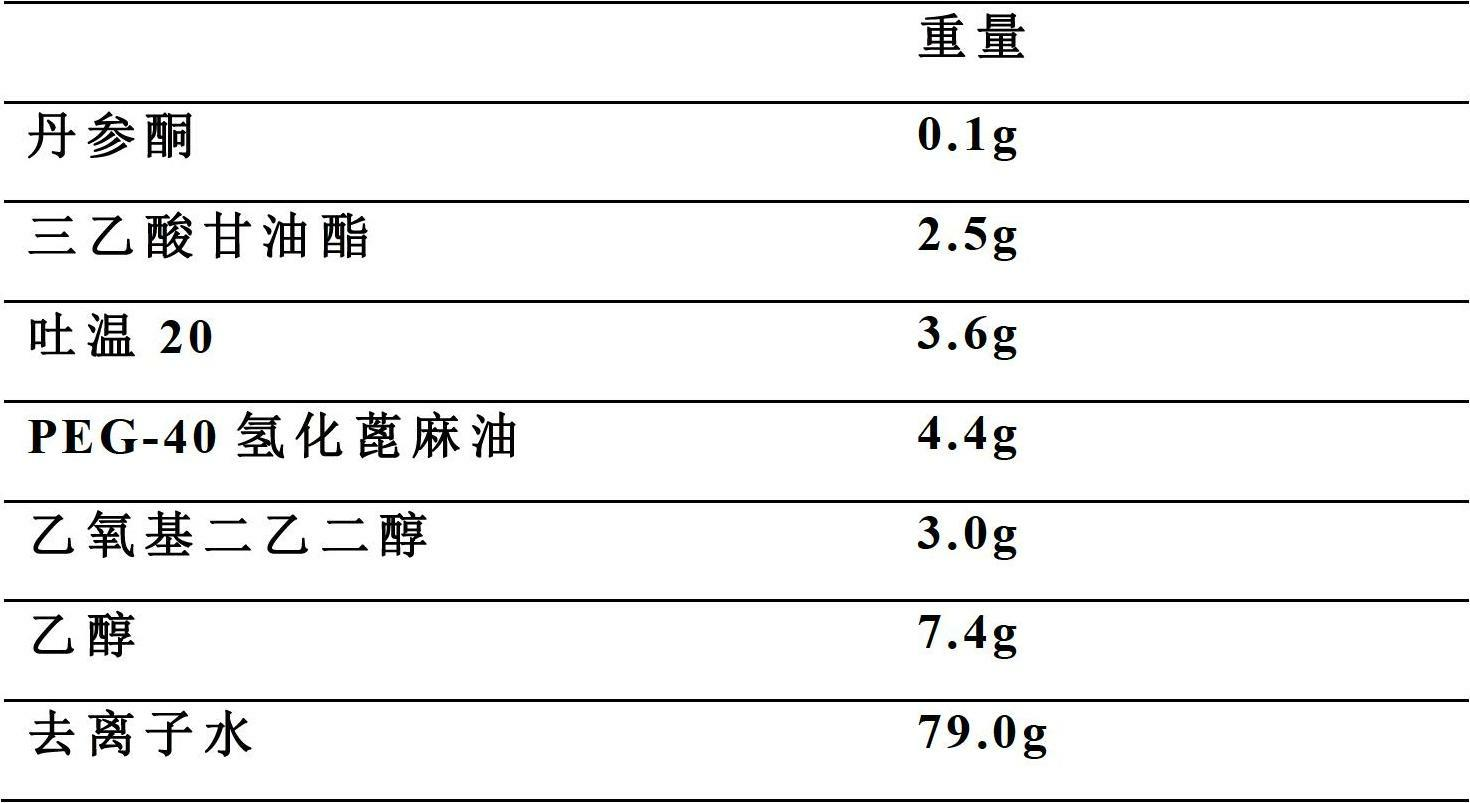

[0048] Composition formula

[0049]

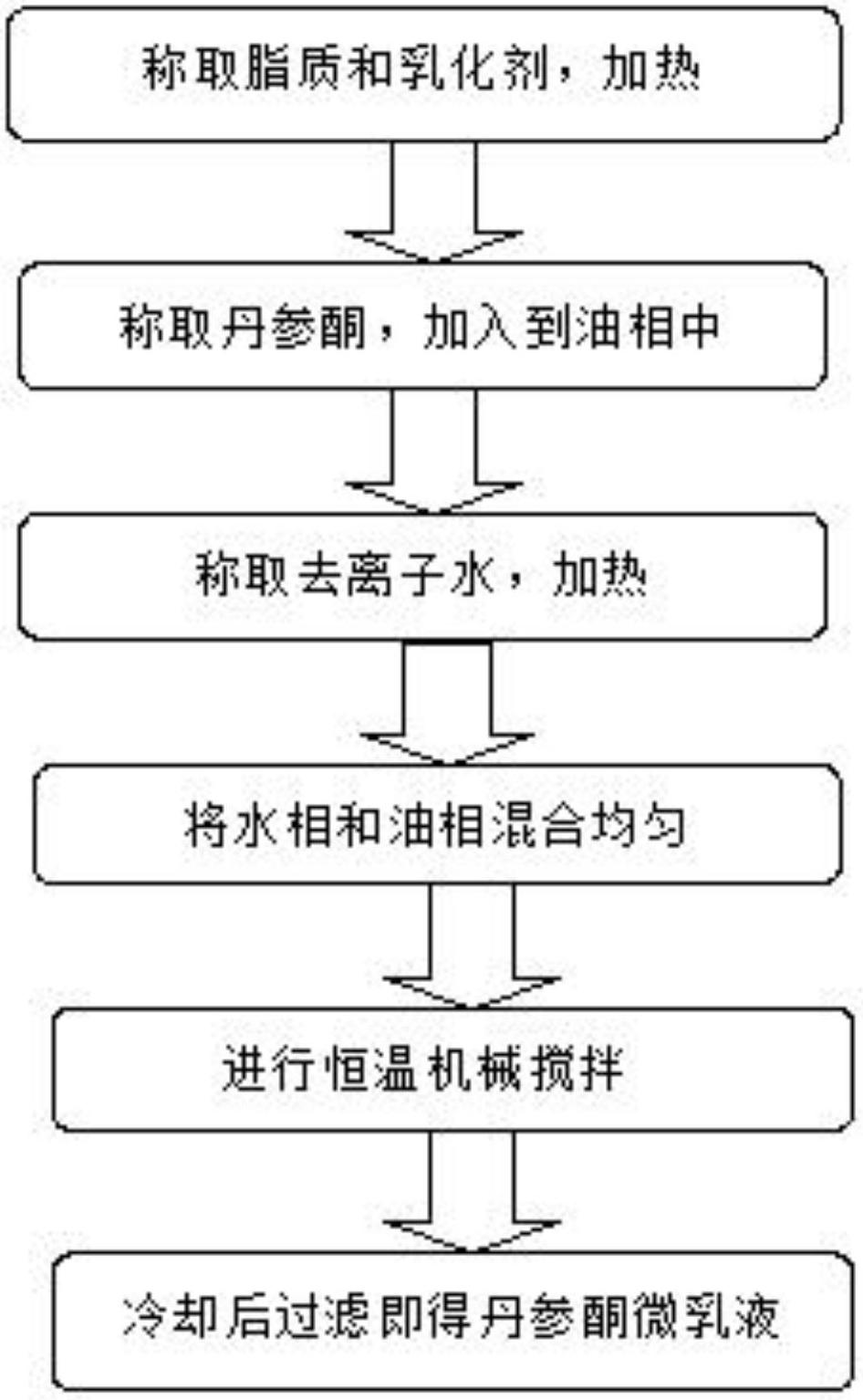

[0050] Such as figure 1 Shown, the preparation steps of this embodiment are as follows:

[0051] 1. Weigh 2.5 grams of triacetin, 3.6 grams of Tween 20, 4.4 grams of PEG-40 hydrogenated castor oil, 3.0 grams of ethoxydiethylene glycol, and 7.4 grams of ethanol into a beaker, and heat in a water bath at 40°C .

[0052] 2. Weigh 0.1 g of tanshinone and add it into the molten oil phase.

[0053] 3. Weigh 79.0 g of deionized water into a beaker, and heat it in a water bath at 40°C.

[0054] 5. Add the water phase to the above system and stir evenly;

[0055] 6. The uniformly stirred high-temperature microemulsion system was cooled and filtered to obtain the microemulsion. The particle size of the microemulsion was measured by photon correlation spectroscopy (PCS) to be 23nm.

Embodiment 2

[0056] The preparation of embodiment 2 tanshinone microemulsions

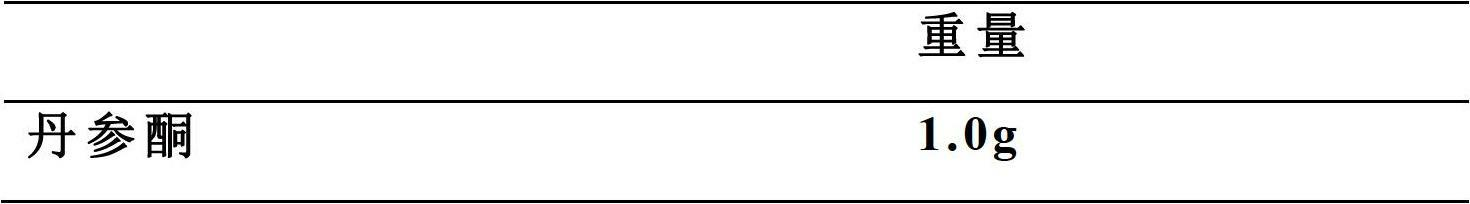

[0057] Composition formula

[0058]

[0059]

[0060] Such as figure 1 Shown, the preparation steps of this embodiment are as follows:

[0061] 1. Weigh 10.0 grams of triacetin, 4.2 grams of Tween 20, 4.0 grams of PEG-40 hydrogenated castor oil, 2.8 grams of ethoxydiethylene glycol, and 8.0 grams of ethanol in a beaker, and heat in a water bath at 40°C .

[0062] 2. Weigh 1.0 g of tanshinone and add it to the molten oil phase.

[0063] 3. Weigh 70.0 g of deionized water into a beaker, and heat it in a water bath at 40°C.

[0064] 5. Add the water phase to the above system and stir evenly;

[0065] 6. The uniformly stirred high-temperature microemulsion system is cooled and filtered to obtain the microemulsion. The particle size of the microemulsion measured by photon correlation spectroscopy (PCS) is 28nm.

Embodiment 3

[0066] The preparation of embodiment 3 tanshinone microemulsions

[0067] Composition formula

[0068]

[0069] Such as figure 1 Shown, the preparation steps of this embodiment are as follows:

[0070] 1. Weigh 12.0 grams of triacetin, 4.5 grams of Tween 20, 5.0 grams of PEG-40 hydrogenated castor oil, 3.2 grams of ethoxydiethylene glycol, and 10.0 grams of ethanol in a beaker, and heat in a water bath at 40°C .

[0071] 2. Weigh 1.8 grams of tanshinone and add it to the molten oil phase.

[0072] 3. Weigh 63.5 grams of deionized water into a beaker, and heat it in a water bath at 40°C.

[0073] 5. Add the water phase to the above system and stir evenly;

[0074] 6. The uniformly stirred high-temperature microemulsion system was cooled and filtered to obtain the microemulsion. The particle size of the microemulsion was measured by photon correlation spectroscopy (PCS) to be 34nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com