Heat-resistant slow-release osmanthus essence microcapsules and its preparation method and application

A technology of essence microcapsule and sweet-scented osmanthus essence, which is applied in the directions of microcapsule preparation, microsphere preparation, essential oil/spice, etc., can solve the problems of heat resistance, low sustained-release property, poor skin compatibility of essence capsules, etc. The method is simple and controllable, with high repeatability and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

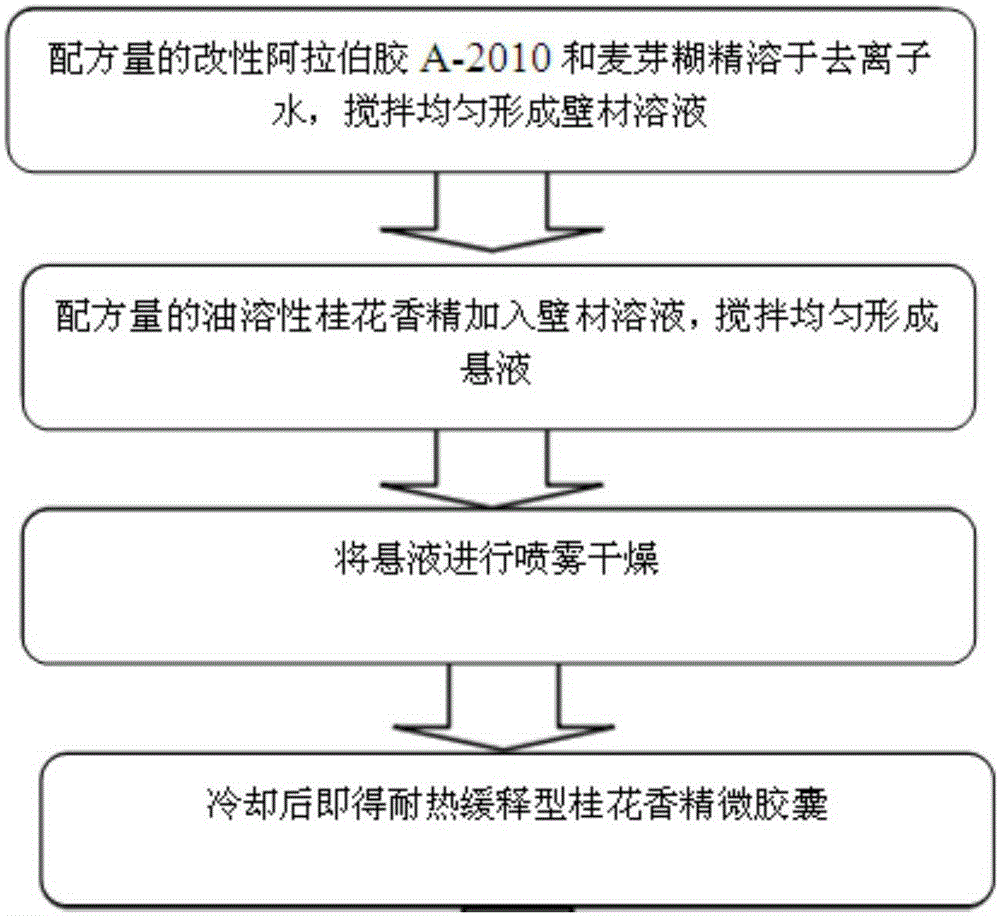

[0032] The preparation method of above-mentioned heat-resistant slow-release type sweet-scented osmanthus essence microcapsules, such as figure 1 shown, including the following steps:

[0033] Step 1. Dissolve the modified gum arabic A-2010 and maltodextrin of the formula in deionized water, and stir evenly at room temperature to obtain a wall material solution, wherein the mass ratio of modified gum arabic A-2010 to deionized water is 1~3:10;

[0034] Step 2. Add the oil-soluble sweet-scented osmanthus essence of the formula into the wall material solution prepared in step 1, stir at room temperature at a stirring rate of 100r / min-500r / min for 10-30min, mix evenly, and form a suspension;

[0035] Step 3. Spray-dry the suspension prepared in Step 2 through a spray dryer, wherein the inlet air temperature is 170-190°C, and the outlet air temperature is 80-90°C;

[0036] Step 4, the spray drier is cooled to room temperature to obtain powdered heat-resistant slow-release osmant...

Embodiment 1

[0039] 1. Weigh 16.62g of modified gum arabic A-2010, 16.63g of maltodextrin, and 65.00g of deionized water into a beaker, heat in a water bath at 25°C, and stir evenly, as a wall material solution;

[0040] 2. Weigh 1.75g of oil-soluble sweet-scented osmanthus essence, add it to the wall material solution, heat in a water bath at 25°C, and stir at 300r / min to form a suspension evenly;

[0041] 3. Spray-dry the suspension, the air inlet temperature is 180°C, the outlet air temperature is 90°C, and the feeding rate of the peristaltic pump is 30r / min;

[0042] 4. After the spray dryer is cooled to room temperature, heat-resistant slow-release sweet-scented osmanthus essence microcapsule powder is obtained. The particle size distribution of the microcapsule powder is 3.6-13.4 μm as measured by a scanning electron microscope. 87.92% (heat treatment at 120°C for 30 minutes in an electric thermostat, measure the absorbance of the sample before and after heat treatment, and calcula...

Embodiment 2

[0044] 1. Weigh 10.28g of modified gum arabic A-2010, 15.43g of maltodextrin, and 70.00g of deionized water into a beaker, heat in a water bath at 25°C, and stir evenly, as a wall material solution;

[0045] 2. Weigh 4.29g of oil-soluble sweet-scented osmanthus essence, add it to the wall material solution, heat in a water bath at 25°C, and stir at 300r / min to form a suspension evenly;

[0046] 3. Spray-dry the suspension, the air inlet temperature is 180°C, the outlet air temperature is 90°C, and the feeding rate of the peristaltic pump is 30r / min;

[0047] 4. After the spray dryer is cooled to room temperature, heat-resistant slow-release sweet-scented osmanthus essence microcapsule powder is obtained. The particle size distribution of the microcapsule powder is 4.2-15.4 μm as measured by a scanning electron microscope. 82.20%, 92.28% of osmanthus flower aroma retention rate after storage at 20°C for three months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com