Catalyst for preparing 1,3-cyclohexanebis(methylamine) by m-xylylenediamine hydrogenation under ammonia reaction conditions

A m-xylylenediamine and catalyst technology, applied in the field of catalysts, can solve the problem of low selectivity of the target product, only 58%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

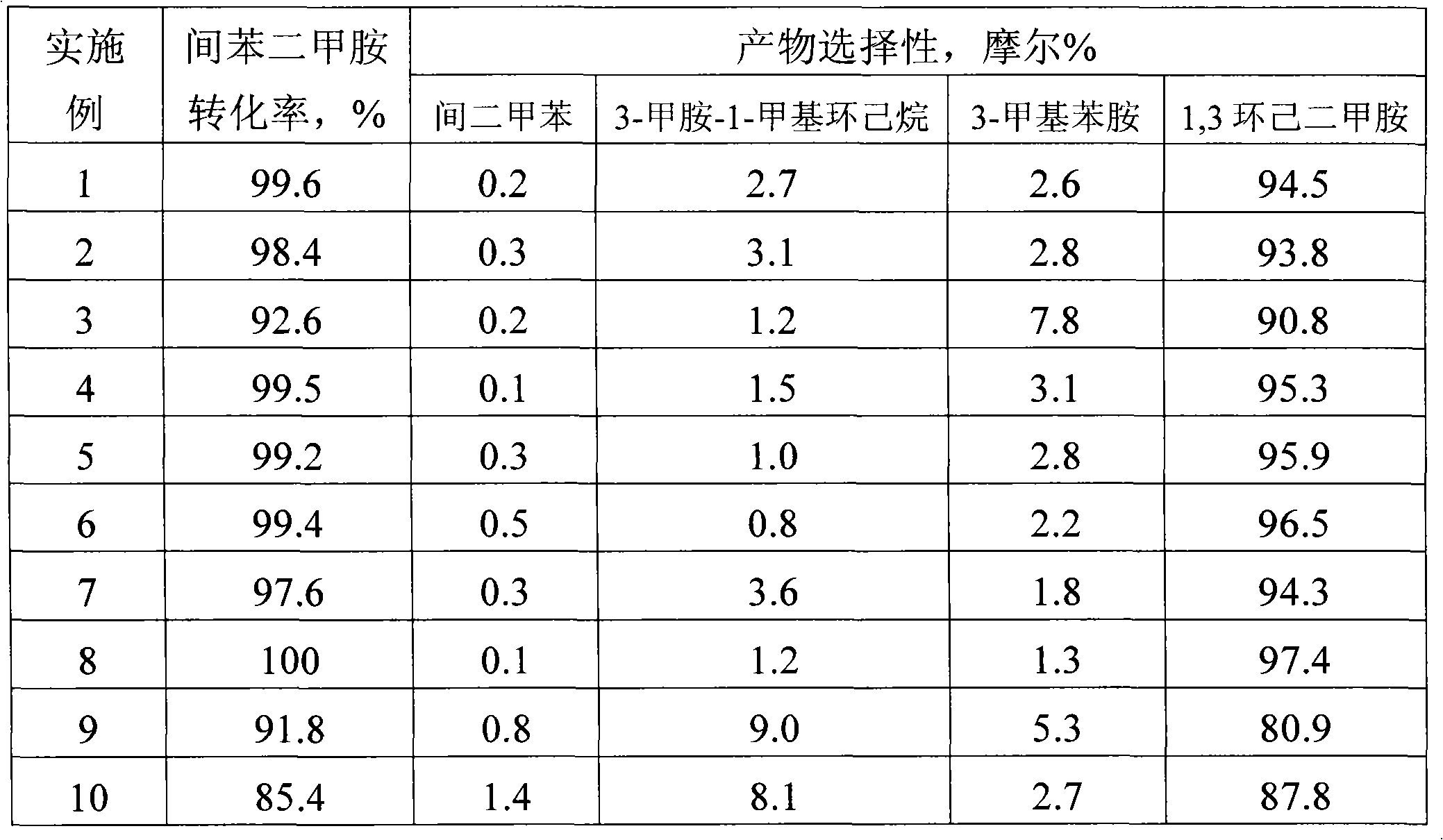

Examples

Embodiment 1

[0022] The catalyst of embodiment 1 is 5%Ru-5%Ni / Al 2 o 3 . Weigh 9.0 g of Al 2 o 3 (20-40 mesh), configuration 15ml contains 1.2933 grams of RuCl 3 ·3H 2 O, 2.4647 g Ni(NO 3 ) 2 ·6H 2 O aqueous solution, impregnating the above Al with this aqueous solution 2 o 3 The carrier was air-dried, oven-dried at 120°C for 4 hours, and baked at 400°C for 4 hours.

Embodiment 2

[0024] Catalyst 5%Ru-5%Ni / coconut shell charcoal of Example 2. Except weighing 9.0 grams of coconut shell charcoal (20-40 mesh (soaked in 3% nitric acid and boiled for 4 hours before use, washed with distilled water to about pH=7.0, dried at 120°C for 6 hours) and no longer roasted, the rest of the preparation steps Same as Example 1.

Embodiment 3

[0026] Catalyst 5%Ru-5%Ni / SiO of Example 3 2 . In addition to weighing 9.0 g of SiO 2 Except, all the other preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com