Titanium alloy bicycle frame welding tool and welding method

A frame welding and welding tooling technology, applied in welding equipment, welding accessories, metal processing equipment, etc., can solve the problems of high welding cost, reduced welding quality, and low work efficiency under vacuum conditions, and achieve efficient short-process production, reduce Difficult to operate, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

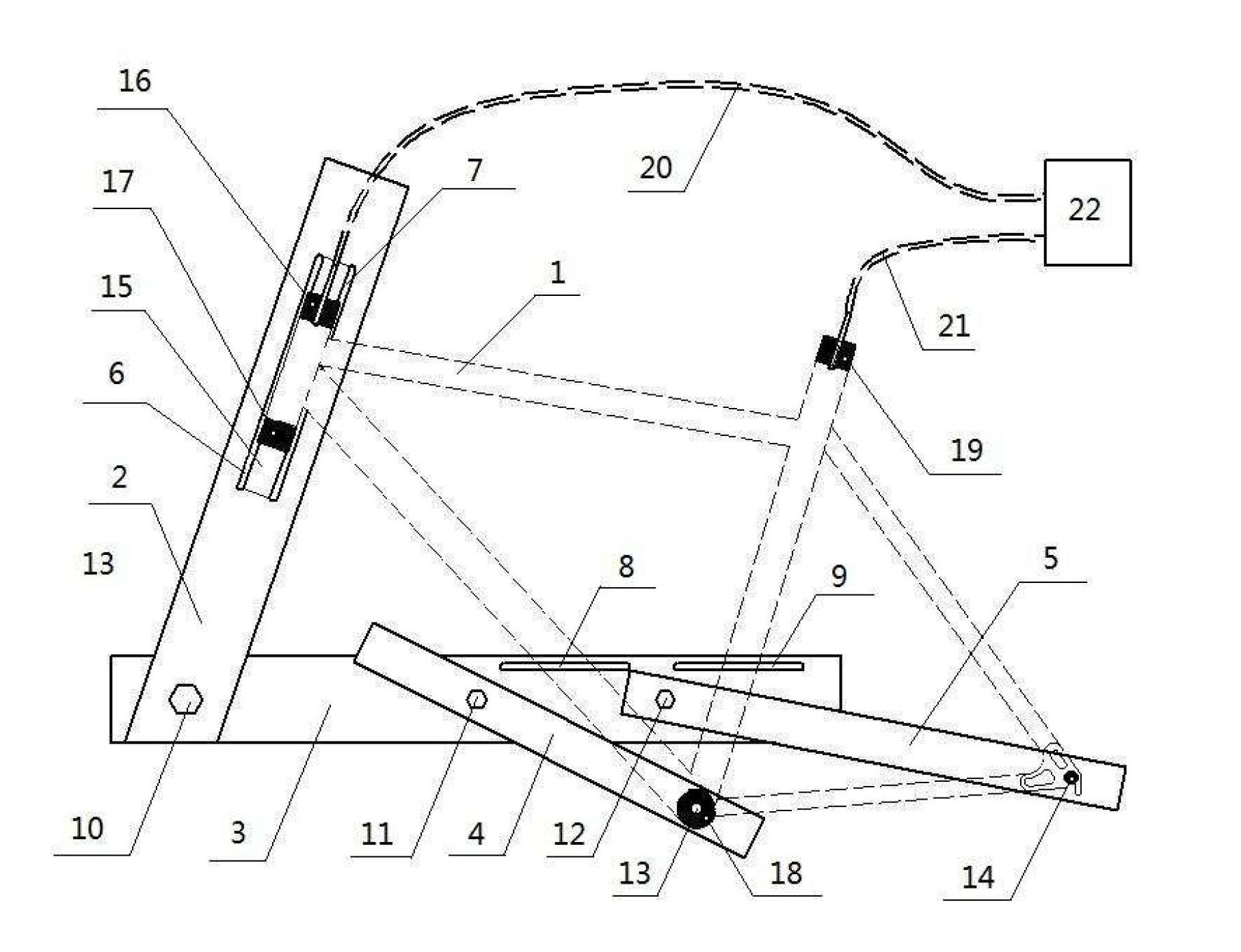

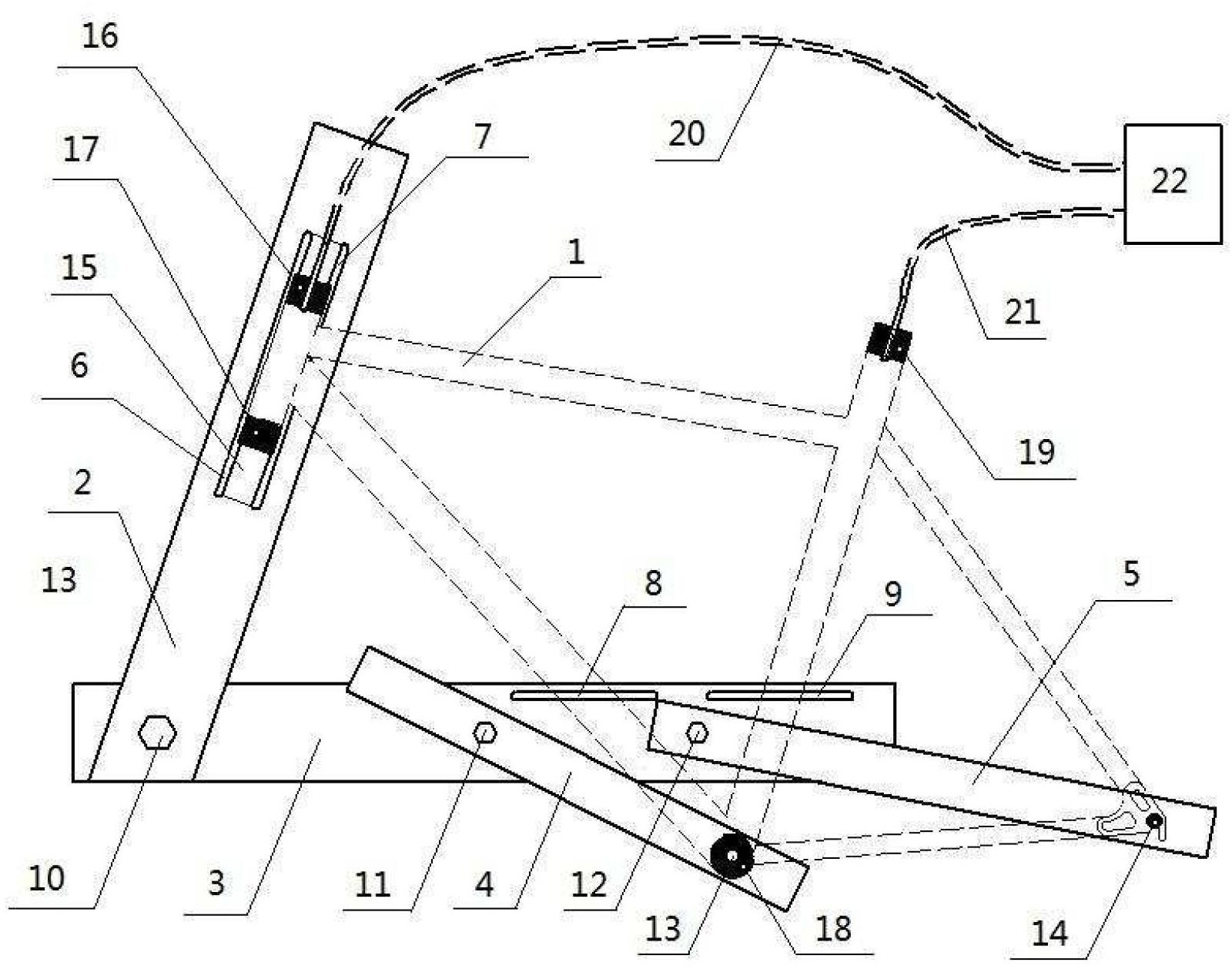

[0026] Embodiment 1 Titanium alloy bicycle frame welding tooling

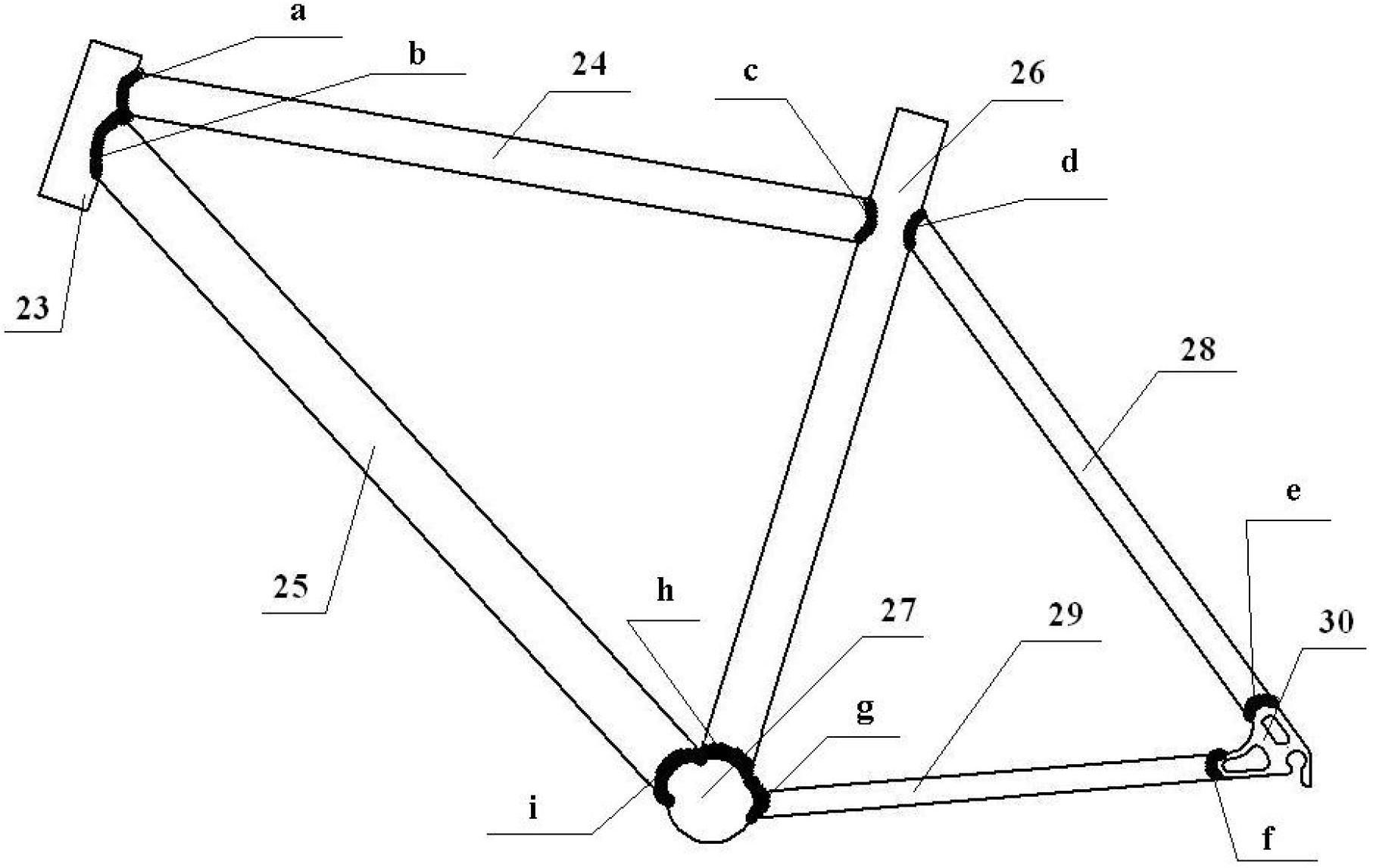

[0027] figure 1 The titanium alloy bicycle frame welding tool shown includes a movable frame 2 for fixing the head tube, a movable frame 4 for fixing the bottom bracket of the seat tube, a movable frame 5 for fixing the seat tube of the rear hook and claws, and a frame body 3, Each movable frame is respectively connected with the frame body 3 by bolts 10, 11, 12, and the angle between the movable frame 2, 4, 5 and the frame body 3 is changed through rotation to adjust the position of each part of the frame body and determine the assembly structure the goal of. Wherein, grooves 6, 7 and slide rails 15 are set on the movable frame 2, the grooves 6, 7 can fix the position of the head pipe by threading the rope, and the slide rail 15 can hold the head pipe and make it move up and down to adjust the position of the head pipe and the head pipe. The welding angle between the upper tube and the lower tube; the movabl...

Embodiment 2

[0029] Embodiment 2 Titanium alloy bicycle frame welding method

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap