Method for deeply processing metal material by aid of laser

A metal material and laser processing technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., to achieve high energy density, small spot, and good beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

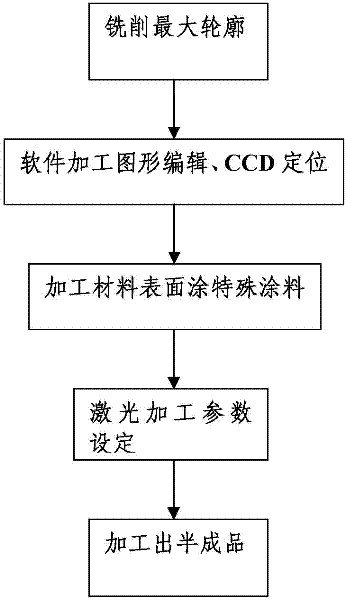

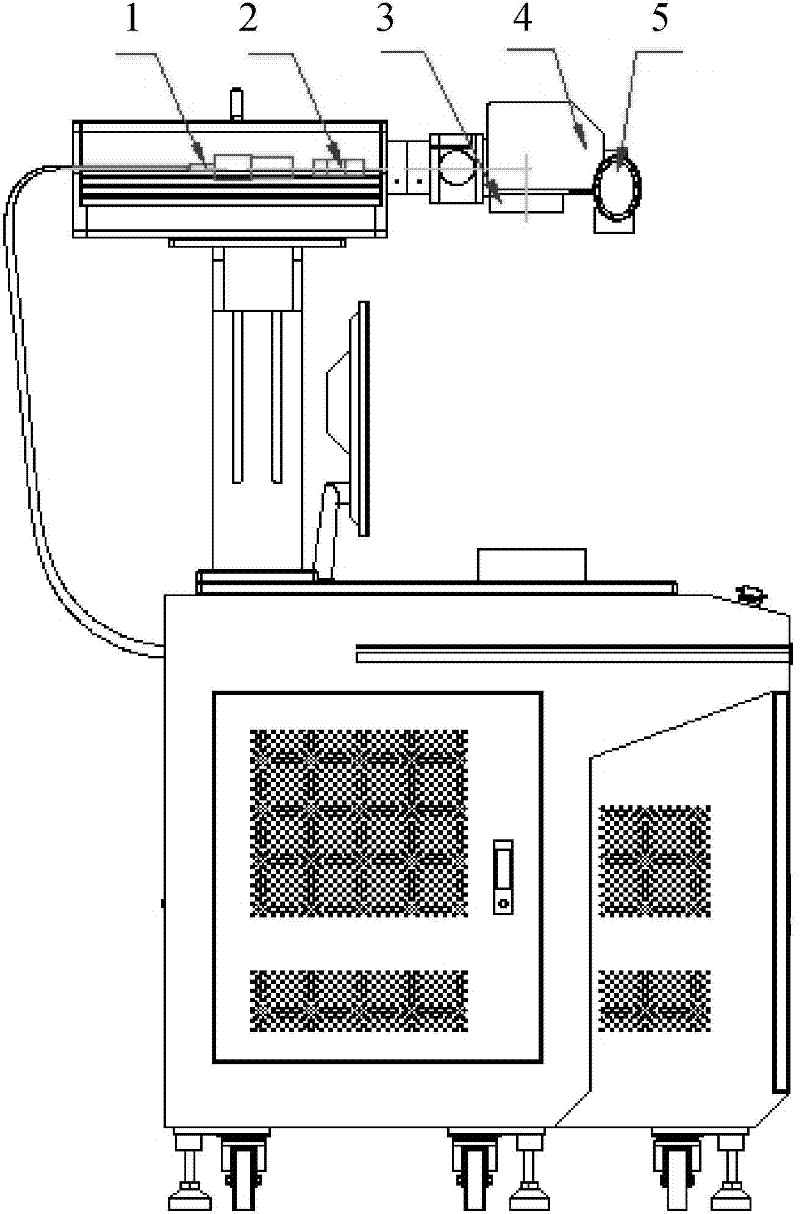

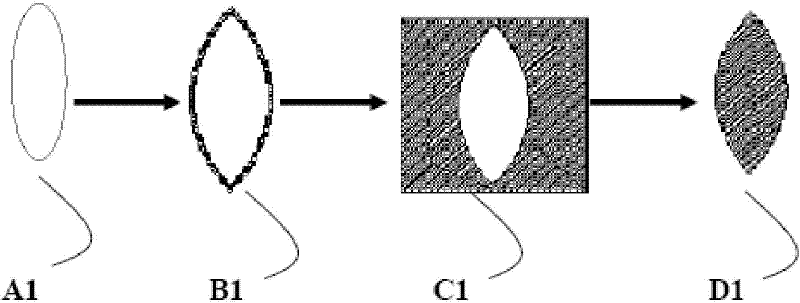

[0044] Take processing a leaf pattern as an example, such as image 3 As shown, on a 1mm thick 6061 aluminum alloy plate (commercially available), process a leaf-shaped pattern (figure size is 15mmx40mm), and the processing depth is 0.3mm; the specific steps are as follows:

[0045] Step A1: first use a milling machine to process the largest outline of the leaf;

[0046]Step B1: Edit the processing part that the engraving and milling machine failed to complete in step A1 in the laser engraving software, and use the CCD positioning system (to identify the position of the graphics that need to be processed, to ensure the relative position of the laser processing graphics and the CNC machining outline) to determine the processing position, and choose a fiber laser with a power of 20W (to provide light source and process energy source), F=160mm focusing lens (to focus the spot formed by the laser after passing through the beam expander, and improve the power density of the spot), ...

Embodiment 2

[0050] Take processing a five-pointed star pattern as an example, such as Figure 4 As shown, on a T magnesium-aluminum alloy plate (brand T934, commercially available) with a thickness of 1mm, process a five-pointed star pattern (figure size is 40mmx40mm), and the processing depth is 0.4mm; the specific steps are as follows:

[0051] Step A2: First use a milling machine to process the largest outline of the five-pointed star;

[0052] Step B2: Edit the processing part that the engraving and milling machine failed to complete in step A2 in the laser engraving software, and use the CCD positioning system (to identify the position of the graphics that need to be processed, to ensure the relative position of the laser processing graphics and the CNC machining contour) to determine the processing position, and choose a fiber laser with a power of 20W (to provide light source and process energy source), F=160mm focusing lens (to focus the spot formed by the laser after passing thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com