Method for preparing sticky rice modified starch with adsorption and sustained release capacity

A technology of modified starch and ability, applied in the field of starch preparation, can solve the problems of space structure damage, reduced adsorption performance, swelling, etc., and achieve the effects of inhibiting swelling, inhibiting water absorption swelling speed, and good water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

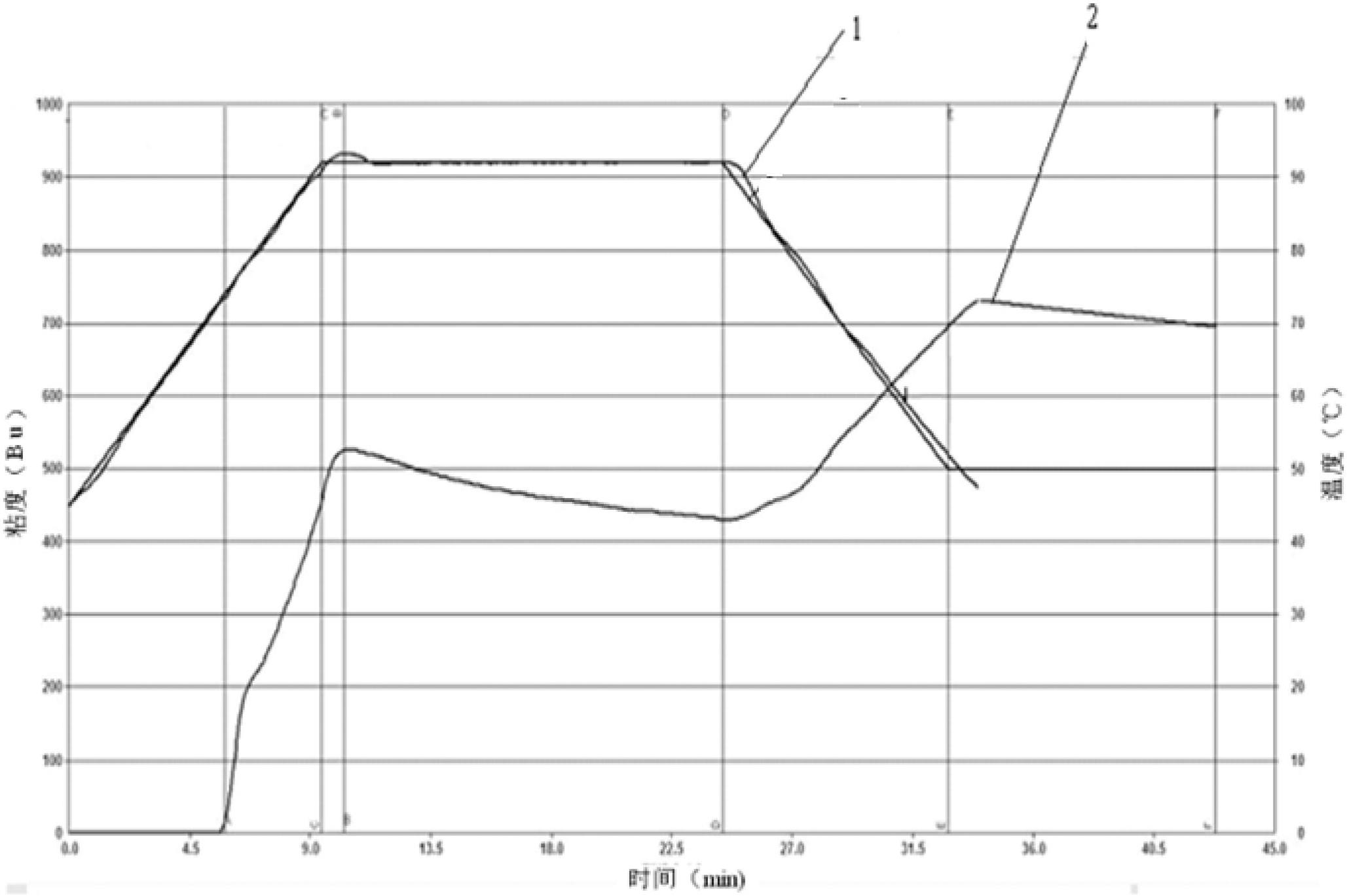

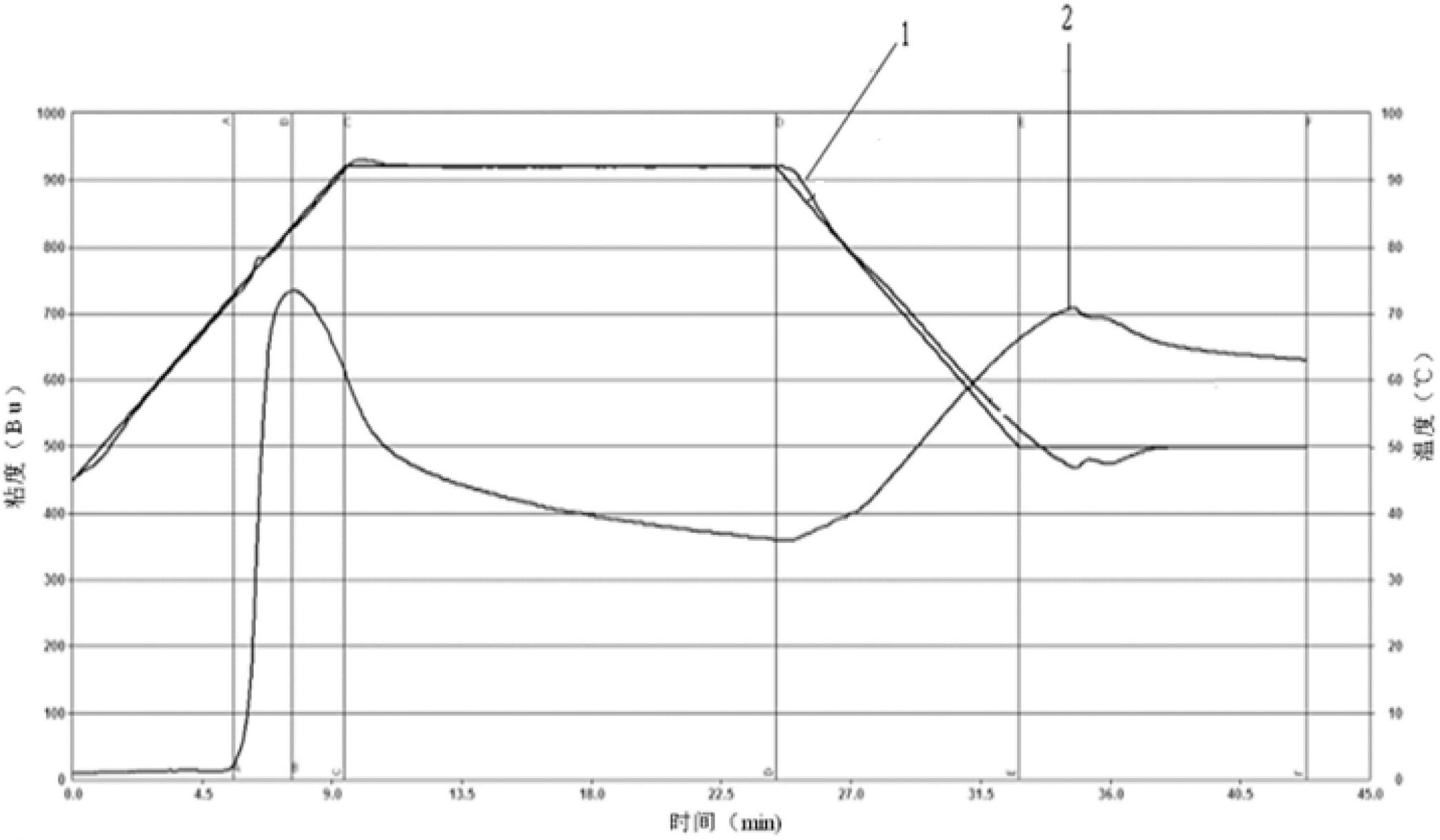

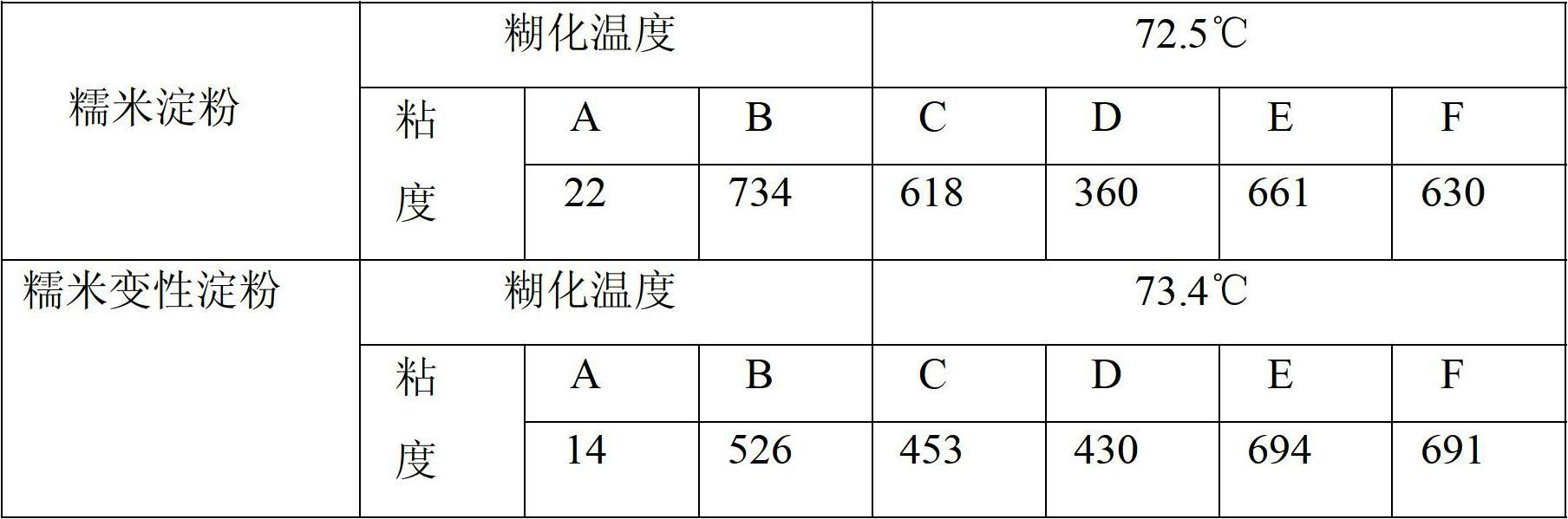

Image

Examples

specific Embodiment approach 1

[0012] Specific implementation mode one: a kind of preparation method of glutinous rice modified starch with adsorption and slow-release ability of this embodiment is carried out through the following steps: 1. Weigh 0.01~0.04 parts of sodium acetate, 0.05~0.08 parts by weight acetic acid, 6000~7000 parts of pure water and 3000~4000 parts of glutinous rice starch were put into a four-neck flask, nitrogen was used as a protective gas, and under the condition of a vacuum of 0.09Mpa, stirred at room temperature for 15~30min, namely Obtain a mixed solution; 2. Heat the mixed solution obtained in step 1 to 41°C~42°C, then add β-amylase for enzymolysis reaction for 18~20h, then add sodium hydroxide and crosslinking agent to carry out crosslinking reaction 3~4h to get the reaction solution; 3. Use 15% hydrochloric acid to adjust the pH value of the reaction solution obtained in step 3 to 5.0~5.5, then filter and wash 3 times, collect the solid phase, and dry at 50~55°C for 8 ~12h, th...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the cross-linking agent described in step 2 is sodium trimetaphosphate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0016] Specific embodiment three: this embodiment is different from specific embodiments one to two in that: the mass volume ratio of the β-amylase described in step two to the mixed solution is 0.24g:100mL. Others are the same as Embodiments 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com