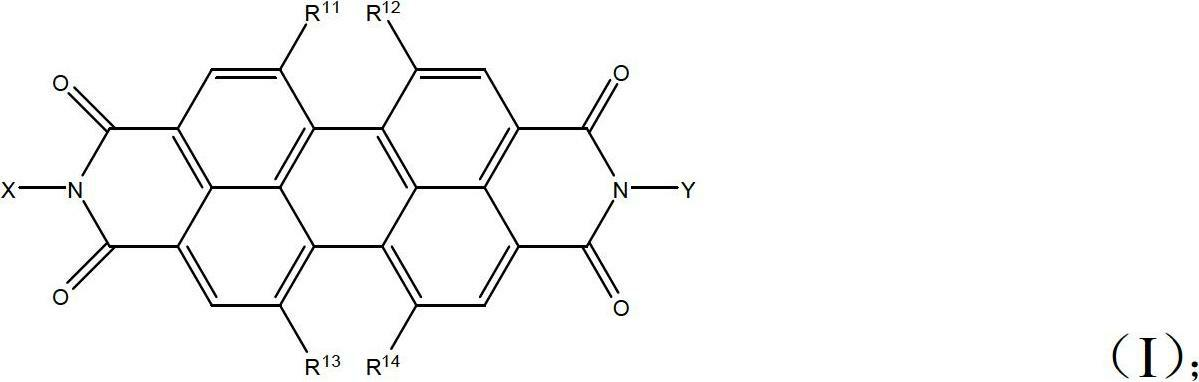

Polymer-based fluorescent functional composite material and fusing process method thereof

A functional composite material and melt processing technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of low fluorescence emission efficiency and poor fluorescence stability, and achieve uniform dispersion, simple processing method, excellent fluorescence and processing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]

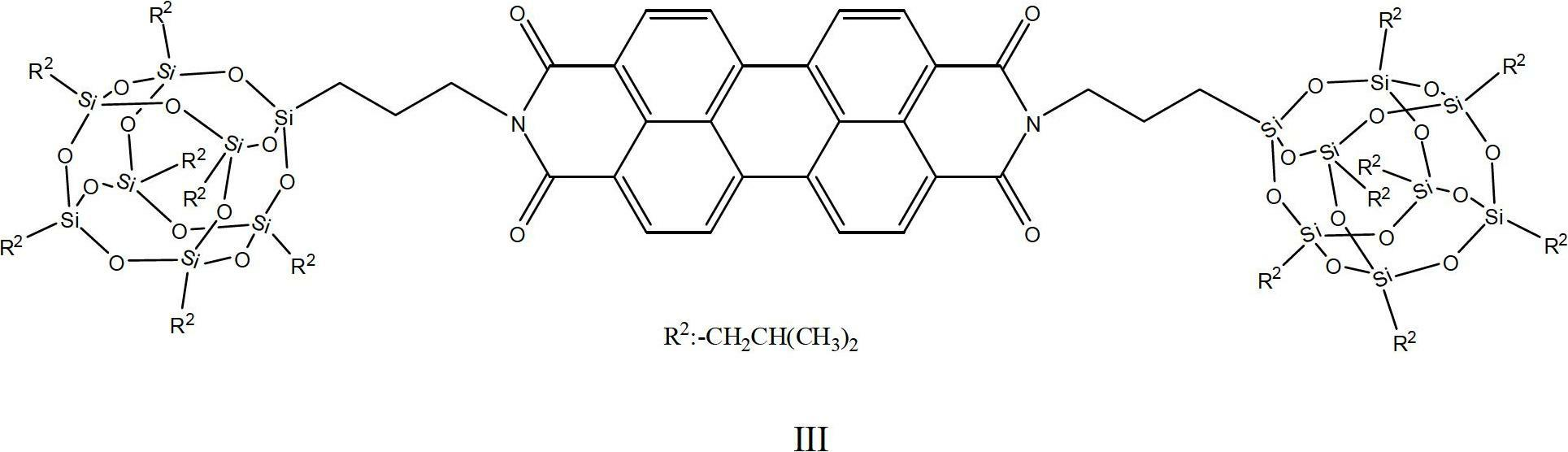

[0035] The matrix material of the composite material is PP slice, and the perylene series fluorescent additive is a compound of crystalline formula (III).

[0036] Grind the perylene-based fluorescent additive crystals dried in vacuum for 3 hours in a ball mill to make it into a powder with a particle size between 10nm and 100um. It is 110°C. The kneaded mixture was dried in vacuum with a vacuum degree of 10KPa and a temperature gradient, the drying temperature was 90°C, and the total drying time was 10h. After drying thoroughly, it is poured into twin-screw extrusion equipment, melted and extruded, and the transmission temperature is 190 ° C. After the melt is extruded, it is drawn and cooled under water to form filaments, and finally enters the pelletizer to cut into pellets to obtain fluorescent functional composites. resin. The composite resin was vacuum-dried, and the drying process was the same as that of the kneaded product in this example, and the weight ...

Embodiment 2

[0044]

[0045] The matrix material of the composite material is PA66 slice, and the perylene series fluorescent additive is a compound of crystalline formula (IV).

[0046] Grind the perylene-based fluorescent additive crystals dried in vacuum for 3 hours in a ball mill to make it into a powder with a particle size between 10nm and 100um. to 190°C. The kneaded mixture was dried in vacuum with a vacuum degree of 2KPa and three temperature gradients, namely 90°C for 10h, 110°C for 10h, and 120°C for 8h. After drying thoroughly, it is poured into twin-screw extrusion equipment, and the melt transfer temperature is 260°C. After the melt is extruded, it is stretched and cooled under water to form filaments, and finally enters a pelletizer to cut into pellets to obtain a fluorescent functional composite resin. Vacuum drying, the drying process is the same as that of the kneaded product in this example, and the weight content of the perylene-based fluorescent additive in the com...

Embodiment 3

[0048]

[0049] The matrix material of the composite material is a PET slice, and the perylene-based fluorescent additive is a compound of the crystalline formula (V).

[0050] Grind the perylene-based fluorescent additive crystals dried in vacuum for 3 hours in a ball mill to make it into a powder with a particle size between 10nm and 100um. to 190°C. The kneaded mixture was dried in vacuum at a vacuum degree of 4KPa, and three temperature gradients were carried out, namely 90°C for 15h, 120°C for 20h, and 130°C for 15h. After drying thoroughly, it is poured into twin-screw extrusion equipment, and the melt transfer temperature is 270°C. After the melt is extruded, it is stretched and cooled under water to form filaments, and finally enters a pelletizer to cut into pellets to obtain a fluorescent functional composite resin. The composite resin was vacuum-dried, and the drying process was the same as that of the kneaded product in this example, and the weight content of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com