Special additive for electrolytic manganese metal and preparation method thereof

A technology for electrolytic metal manganese and additives, applied in the field of electrolytic metal manganese production, can solve the problems of high electrolytic energy consumption, harsh production conditions, self-toxicity, etc., and achieve the effects of simple preparation process, clear and transparent appearance, and stable properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

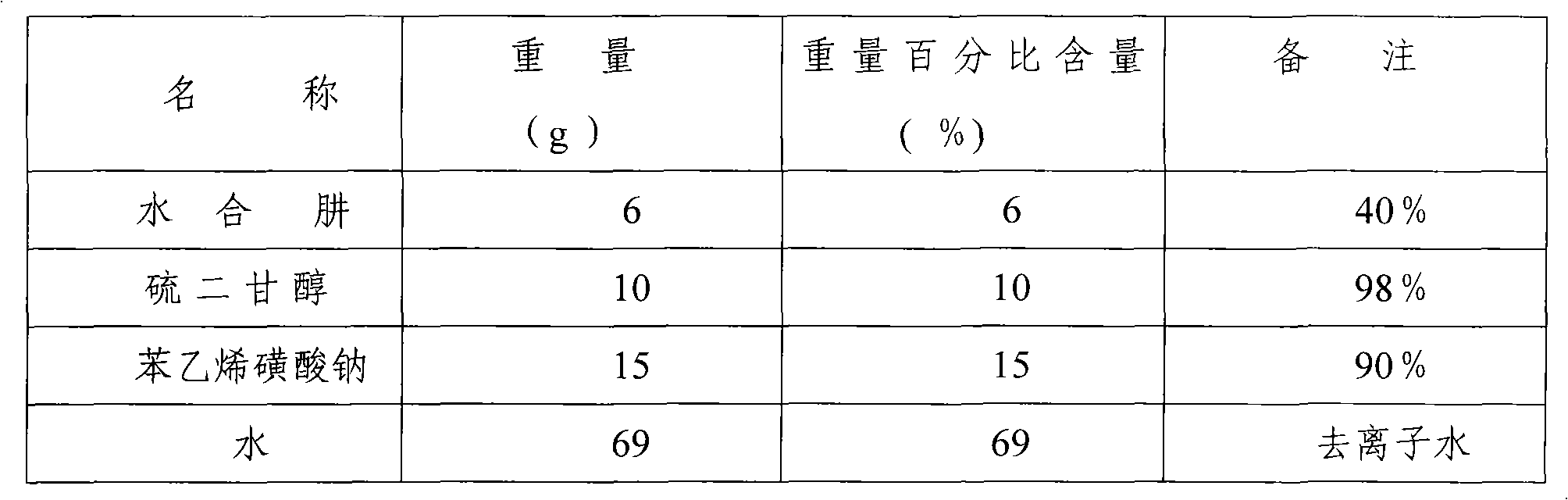

[0027] A special additive for electrolytic manganese, the percentage by weight of each raw material is shown in Table 1.

[0028] Table 1

[0029]

[0030] The above-mentioned preparation method for the special additive for electrolytic manganese comprises the following steps:

[0031] 1 Selection of raw materials: select each raw material according to Table 1:

[0032] 2. First add water to the reactor and heat it to 50-60°C, then add sodium styrene sulfonate, stir for 30 minutes until the sodium styrene sulfonate is completely dissolved, cool to room temperature, then add hydrazine hydrate and thiodiglycol, Stir evenly to obtain the special additive for electrolytic manganese (additive No. 1).

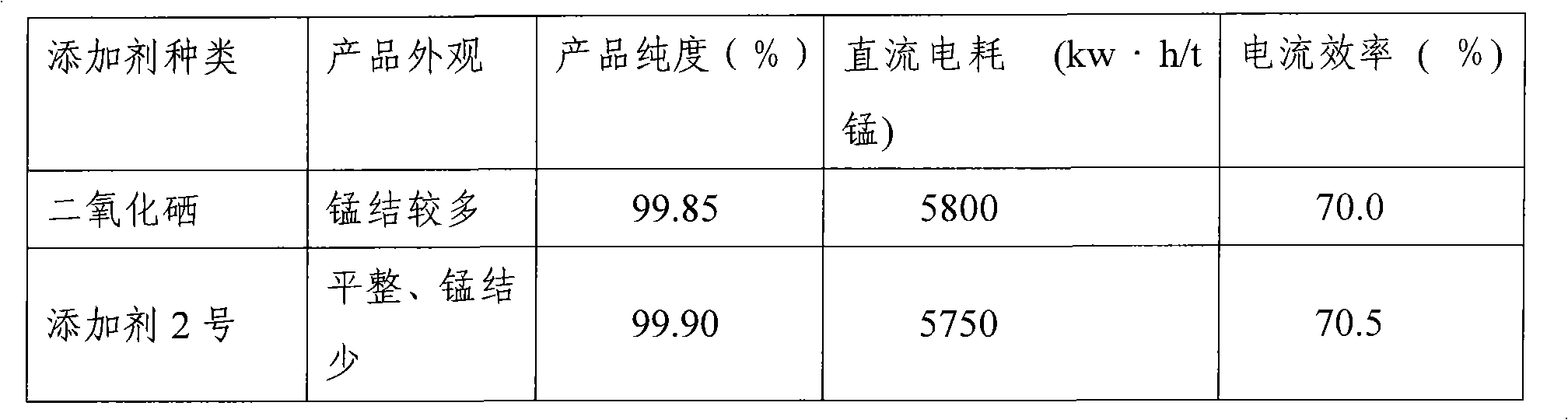

[0033] The prepared additive No. 1 was used in the production of electrolytic manganese, and a comparative test was carried out on the 5000t / a electrolytic manganese production line with that of completely using selenium dioxide. The technical indicators were as follows: qualifi...

Embodiment 2

[0037] A special additive for electrolytic manganese, the weight percentage of each raw material is shown in Table 3.

[0038] table 3

[0039] name

Weight (g)

Weight percentage content (%)

Remark

Hydrazine hydrate

8

8

40%

14

14

98%

30

30

25% (liquid)

water

48

48

Deionized water

[0040] The above-mentioned preparation method for the special additive for electrolytic manganese comprises the following steps:

[0041] 1 Selection of raw materials: select each raw material according to Table 3:

[0042] 2. Add water, hydrazine hydrate, thiodiglycol, and sodium propyne sulfonate to the reaction kettle in sequence, and stir evenly to obtain the special additive for electrolytic manganese (additive No. 2).

[0043] The prepared additive No. 2 was used in electrolytic manganese production, and a comparative test was car...

Embodiment 3

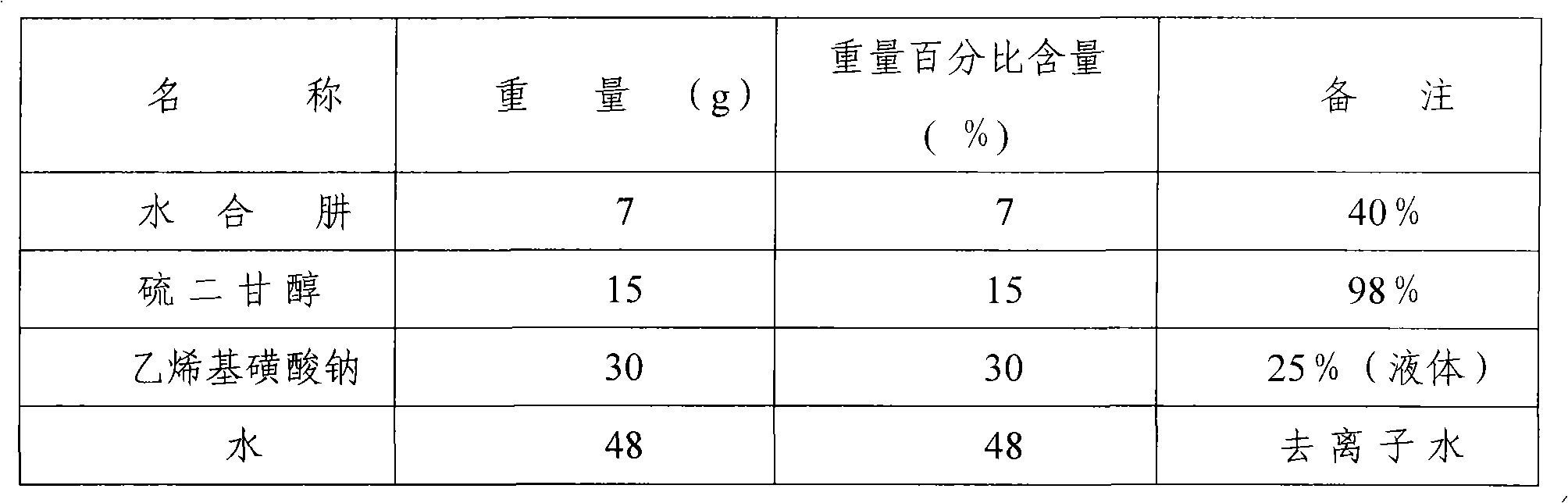

[0047] A special additive for electrolytic manganese production, the weight percentage of each raw material is shown in Table 5.

[0048] table 5

[0049]

[0050] Above-mentioned a kind of preparation method that is used for the special additive of electrolytic manganese production comprises the following steps:

[0051] 1. Selection of raw materials: select each raw material according to Table 5:

[0052] 2. Add water, hydrazine hydrate, thiodiglycol, and sodium vinylsulfonate to the reaction kettle in sequence, and stir evenly to obtain a special additive for electrolytic manganese (additive No. 3).

[0053] The prepared additive No. 3 was used in the production of electrolytic manganese, and a comparative test was carried out with selenium dioxide on a 5000t / a electrolytic manganese production line. The technical indicators were as follows: qualified liquid: manganese content 32-36g / l, ammonium sulfate content 80-100g / l, selenium dioxide content 8-12mg / l, pH value 6.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com