Off-line steam drawing process method of polyacrylonitrile-based protofilament

A process method and technology of raw silk, applied in liquid/gas/steam textile material processing, textile and papermaking, textile material processing, etc. Problems such as large draft multiples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

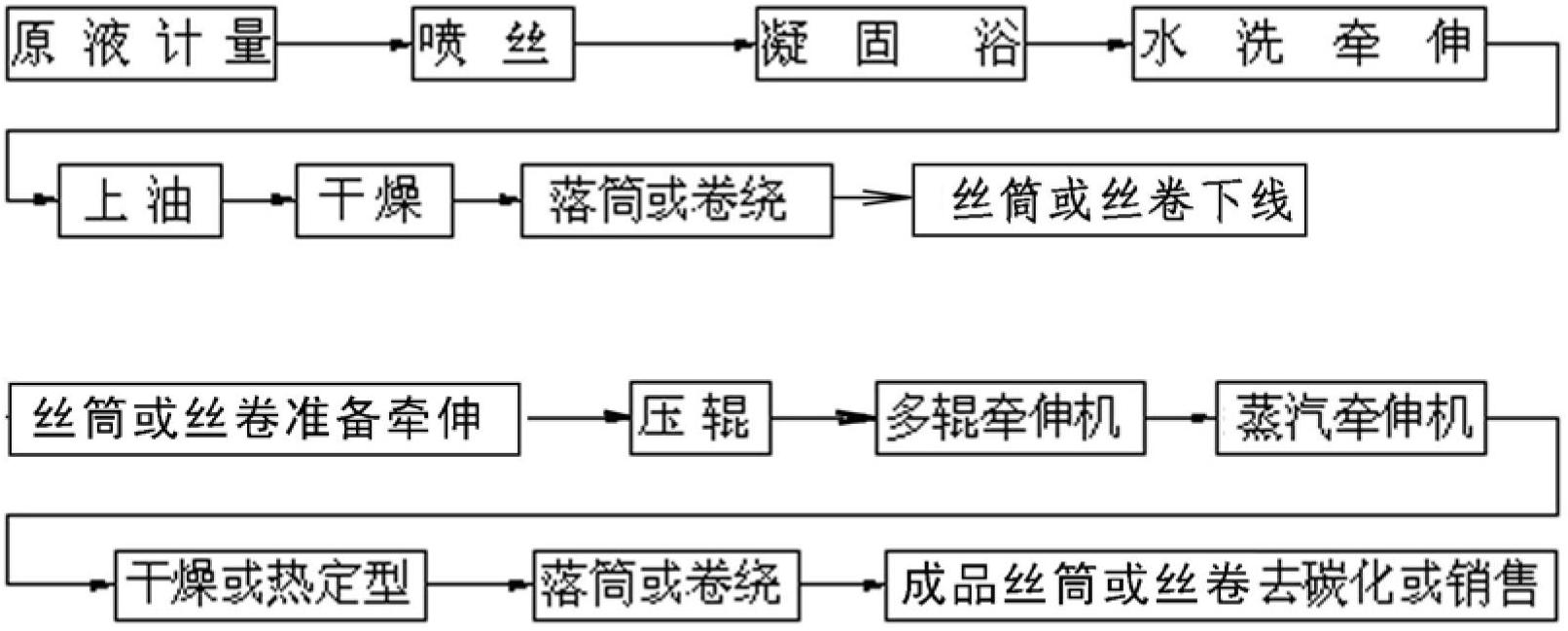

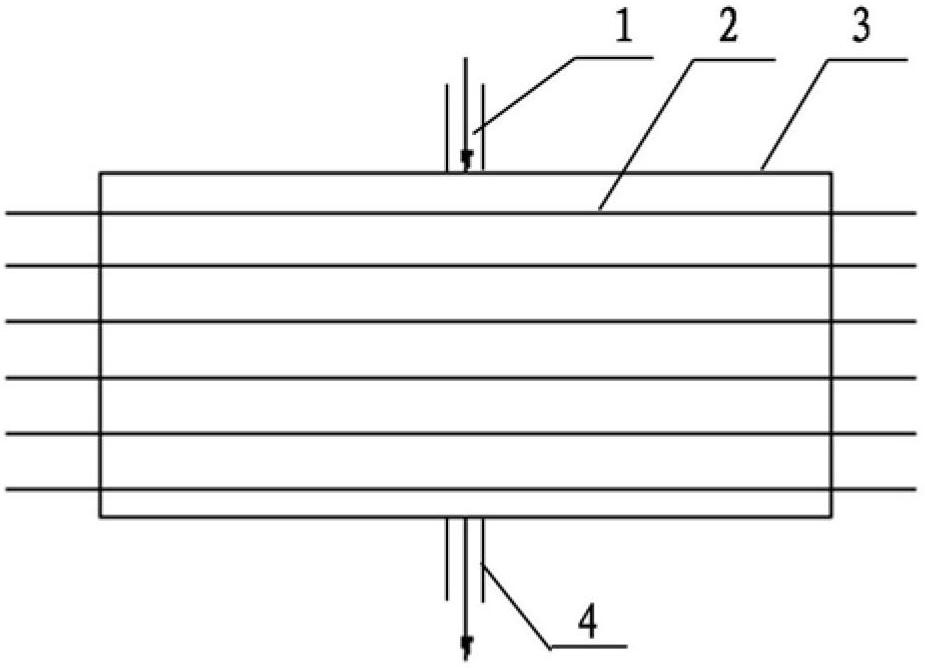

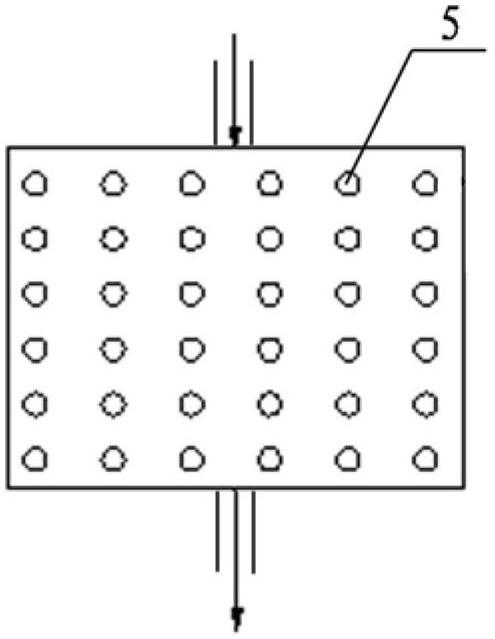

[0014] The invention discloses an off-line steam-drawing process for polypropylene nitrile-based raw silk, which is an improved technology aimed at the shortcomings formed in the existing on-line steam-drawing production. Such as figure 1 As shown, the off-line steam drawing process of polypropylene acrylonitrile-based raw silk includes two separate production lines before and after. Winding, raw silk tubes or coils to be drawn off the line; the next production line is: the raw silk tubes or coils to be drawn are sent to press rollers in batches, multi-roller drafting machine, steam drafting machine, drying Or heat setting, doffing or winding, to obtain the finished product of polyacrylonitrile-based raw silk, that is, the finished raw silk after steam drawing.

[0015] Use the following steps to realize the separation of the production line for steam drawing:

[0016] Step 1: After the dryer and before the steam drafting machine of the raw silk production line, install a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com