Method for manufacturing micro-nano pyramid gallium nitride based light-emitting diode array with vertical structure

A technology of micro-nano pyramids and light-emitting diodes, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve the problems of large reverse leakage and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

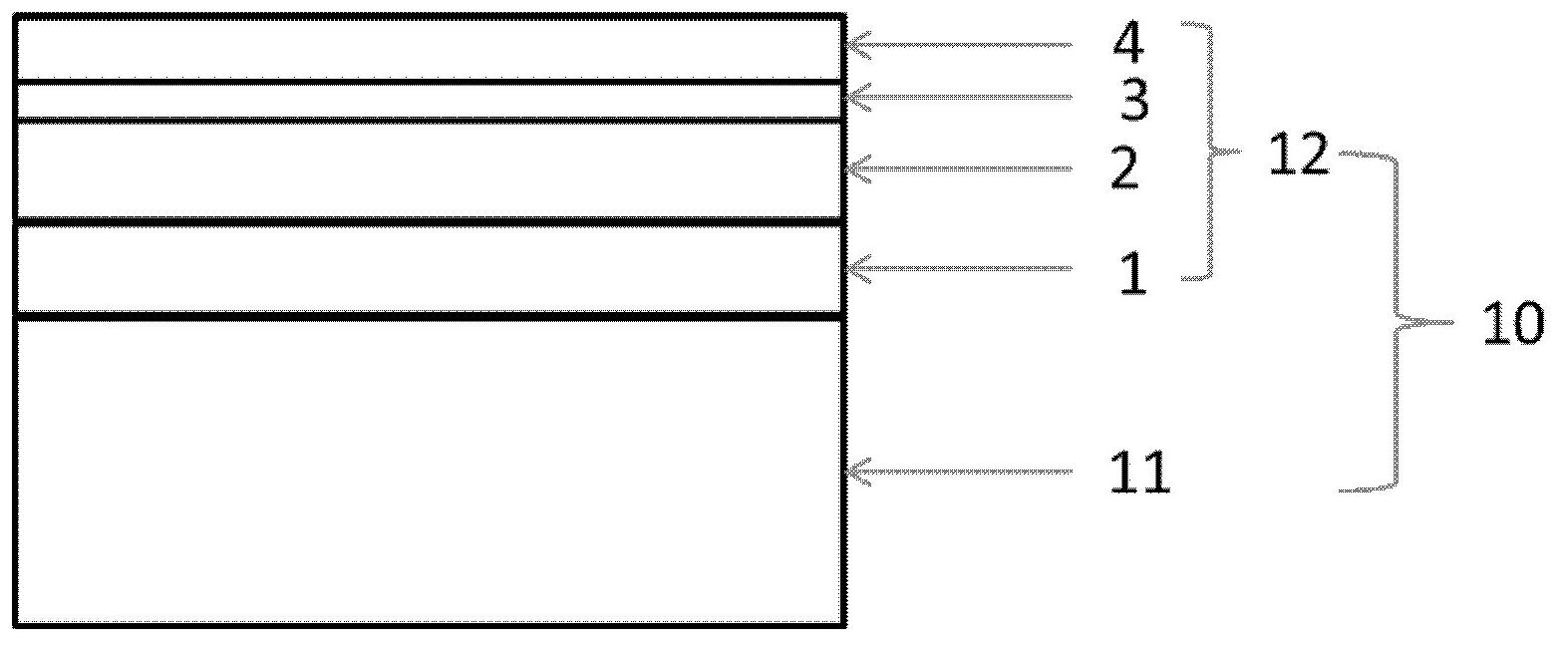

[0036] see Figure 1 to Figure 5 As shown, the present invention provides a method for making a micro-nano pyramid gallium nitride-based vertical structure light-emitting diode array, comprising the following steps:

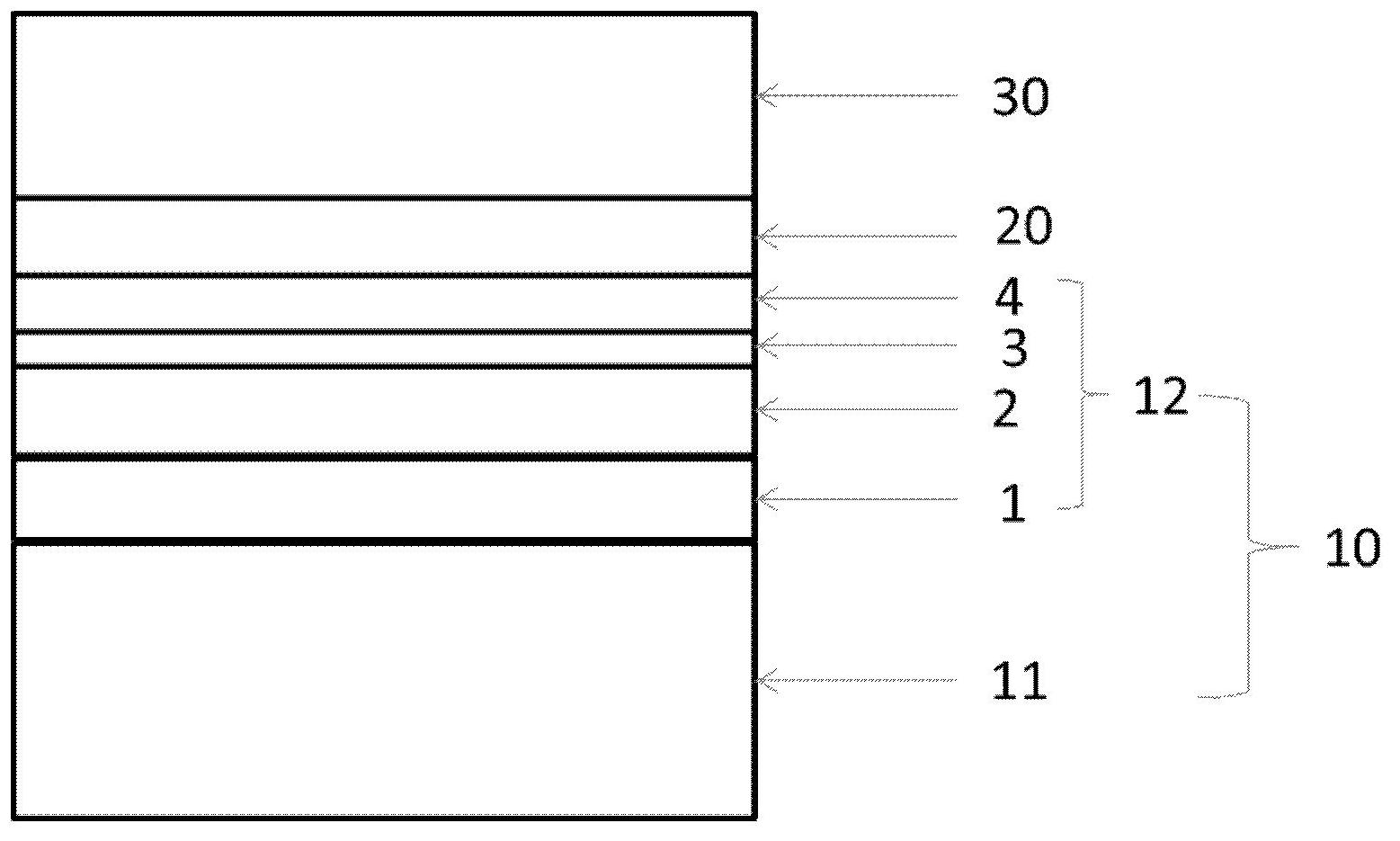

[0037] Step 1: Select an epitaxial structure 10 including a sapphire substrate 11 and a gallium nitride LED layer 12 in sequence. The gallium nitride LED layer 12 includes an unintentionally doped gallium nitride layer 1 (2 μm), an n-type gallium nitride layer 2 (2 μm), a quantum well layer 3 (100 nm), and a p-type gallium nitride layer 4 (100 nm);

[0038] Step 2: Depositing a metal layer 20 on the p-type gallium nitride layer 4, the metal layer 20 is Ni\Ag\Pt\Au multilayer metal;

[0039] Step 3: Electroplating Cu\Ni multilayer metals sequentially on the metal layer 20 by an electroplating method to form a substrate

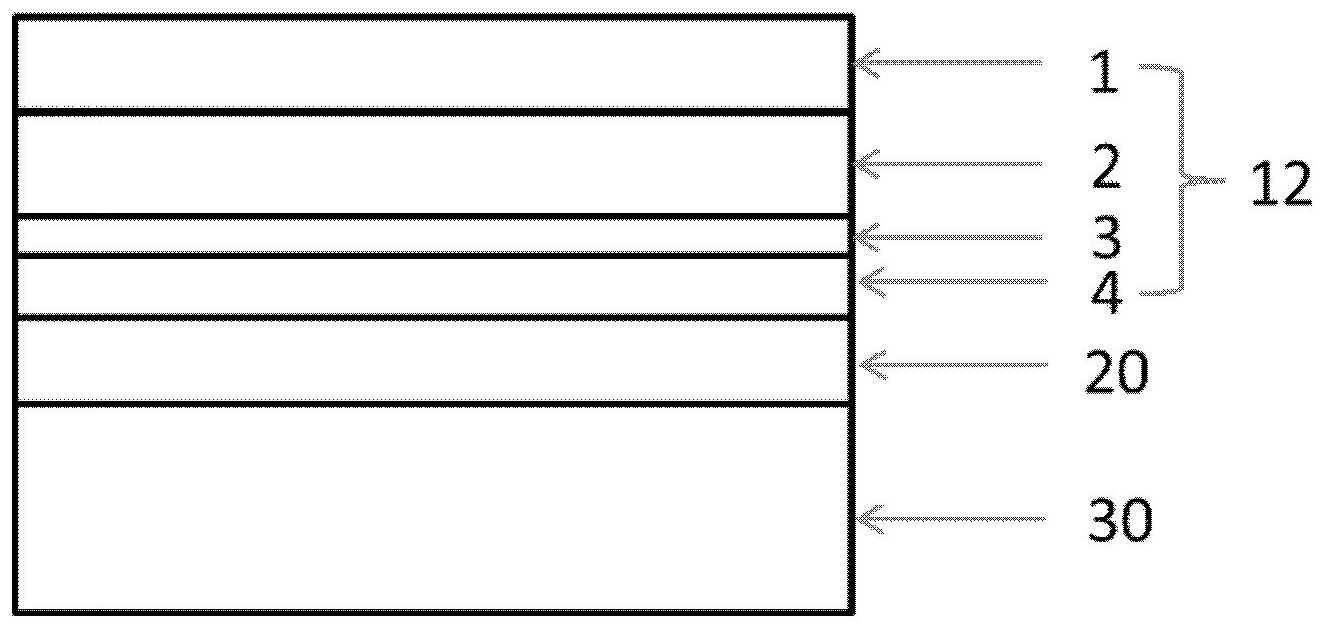

[0040] Step 4: using a laser lift-off method to separate the sapphire substrate 11 from the epitaxial layer 12;

[0041] Step 5: Etching the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com