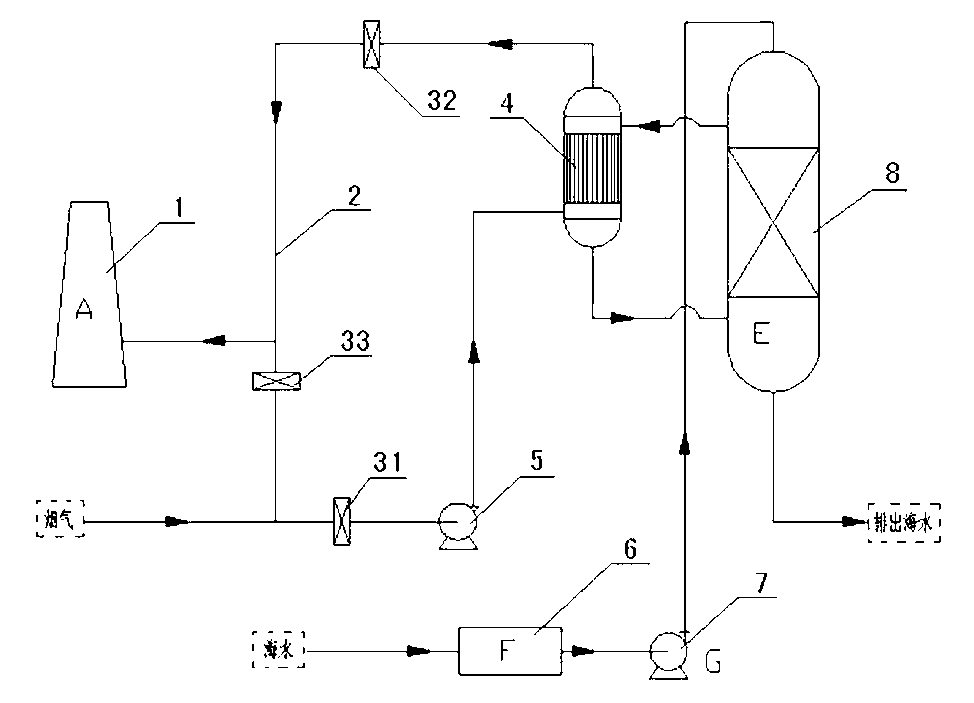

Method and device for desulfurizing tail gas of ship engine by electrolytic method by using sea water

A technology of tail gas treatment and electrolysis, which is applied in the field of ships, can solve the problems of limited ship space, relatively strict installation size requirements for desulfurization equipment, and affect the application of seawater desulfurization, and achieve the effect of reducing the occupied area, reducing the volume, and changing the balance of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] SO in flue gas 2 The concentration is 4900 mg / m 3 , the temperature of entering the tower is 40°C; the concentration of NaClO produced by electrolysis of natural seawater is 6 mg / L, and the liquid-gas ratio is 2.5 L / m 3 , its desulfurization efficiency was 94%.

Embodiment 2

[0042] SO in flue gas 2 The concentration is 2300 mg / m 3 , the temperature entering the tower is 75°C; the concentration of NaClO produced by electrolysis of natural seawater is 10 mg / L, and the liquid-gas ratio is 4.4 L / m 3 , the desulfurization efficiency is 91%.

Embodiment 3

[0044] SO in flue gas 2 The concentration is 1300 mg / m 3 , the inlet temperature is 95°C; the concentration of NaClO produced by electrolysis of brine with a salinity of 35PSU is 15 mg / L, and the liquid-gas ratio is 6.1 L / m 3 , its desulfurization efficiency was 96%.

[0045] The invention uses the sodium hypochlorite solution produced by electrolyzing seawater to replace the original natural seawater as the adsorbent. Sodium hypochlorite solution oxidizes sulfite dissolved in seawater to sulfate, which changes the dissolution balance between sulfur dioxide and seawater, and improves the absorption speed of seawater to sulfur dioxide. This method not only saves the aeration tank in the original seawater desulfurization process, but also improves the SO concentration per unit volume of seawater. 2 The absorption efficiency greatly reduces the volume of the absorption tower and realizes the application of seawater desulfurization technology in ships. The main reaction formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com