Method for recovering scandium from titanium dioxide wastewater on large scale

A technology for titanium white wastewater and wastewater, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve problems such as inability to store, poor separation, and small processing capacity, and achieve guaranteed purity, high purity, and processing capacity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

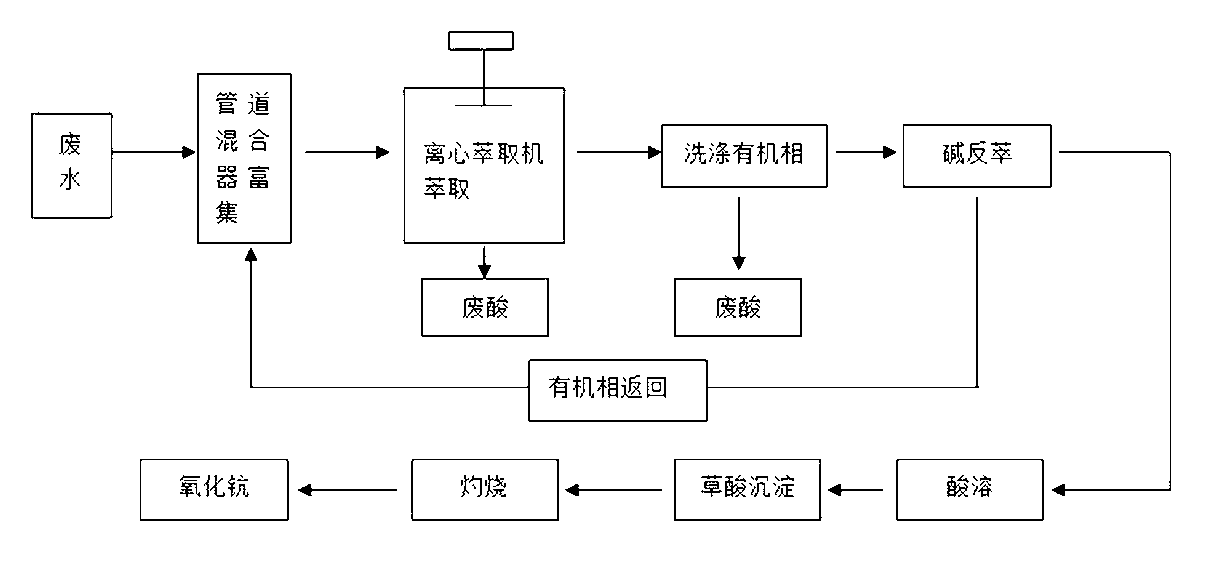

Method used

Image

Examples

Embodiment 1

[0030] Pipeline mixer ¢260×1.5mm, with CML-550 centrifugal extractor, flux 50m 3 / h, waste acid is 5molH 2 SO 4 , including Sc 2 o 3 12mg. / L, TiO 2 6g / L, the extraction agent is 15%P507+kerosene, the ratio is O / A=1 / 15, the extraction time is 6 seconds, the extraction rate of scandium is 95%, and the organic phase content in the aqueous phase is less than 100mg / L, discharge. Load organic phase with 5mol / L H 2 SO 4 + 1%H 2 o 2 Mixed liquid washing, compared with O / A=1 / 2, 15 grades, titanium removal rate> 85%, after washing the organic phase, use 3mol / L NaOH as stripping agent, compared with O / A=2 / 1, The temperature is 70°C, the stripping rate of scandium is >98%, and the organic phase is back-extracted with alkali, and then 1mol / L H 2 SO 4 Washing treatment, return to the extraction section, after the stripping precipitate is filtered, use 6mol / L HNO 3 Dissolve, and add 1% tartaric acid to adjust the acidity, filter the solution and add oxalic acid to precipitate scan...

Embodiment 2

[0032] Pipeline mixer ¢230×1.2mm, with CML-550 centrifugal extractor, flux 30m 3 / h, the extractant is 40%P507+kerosene, the ratio is O / A=1 / 50, the extraction time is 10 seconds, the scandium extraction rate is 98%, and the organic phase is loaded with 2mol / L H 2 SO 4 + 4%H 2 o 2 Washing, compared to O / A=2 / 1, 10 levels. The stripping organic phase is 5mol / L NaoH, O / A=1 / 3, the temperature is 50°C, and the scandium stripping rate is 99%. Dissolve the alkali cake with 2mol / L HCl, adjust the acidity, add 1% EDTA, stir and filter, the filtrate is precipitated with oxalic acid, and the scandium oxalate is burned at 700°C for 4 hours to obtain 98% scandium oxide.

Embodiment 3

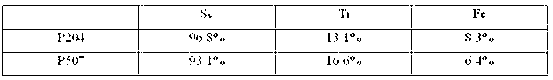

[0033] Example 3 The comparative experimental results of P507 and P204 extraction

[0034] Extraction conditions: 25% P204+kerosene and 25% P507+kerosene, O / A=1 / 20, t=20 minutes, separatory funnel

[0035] Stripping conditions: 2N NaOH, O / A=1 / 2,

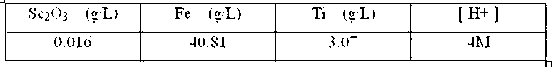

[0036] Table 1 Substance content in feed liquid

[0037]

[0038] Table 2 Analysis of organic phase after extraction (unit: g / L)

[0039]

[0040] Table 3 Comparison of extraction rates of P204 and P507

[0041]

[0042] Table 4 Analysis of organic phase extraction rate after extraction

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com