Equipment for treating industrial wastewater by crystallization method

A technology for industrial wastewater and crystallization equipment, which is applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of high stirring speed, uneven stirring in the stirring zone, and the decline of MAP crystal precipitation effect, etc. problems, to achieve the effect of high turbulence, good energy dissipation effect and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

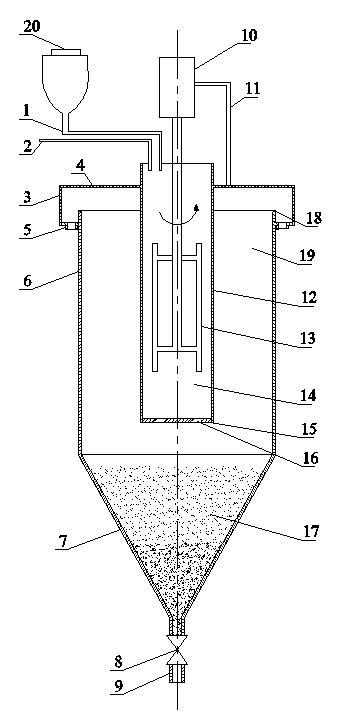

[0016] as attached figure 1 Shown: the equipment for treating industrial wastewater by the crystallization method of the present invention includes a filter 20, the filter is connected to the crystallization equipment, and the crystallization equipment includes the cylinder wall 6 of the precipitation zone, and the cylinder wall of the precipitation zone is fixedly connected The outer wall 3, the cylinder wall of the settling zone and the outer wall form an overflow weir 18, the outer wall has a water outlet 5 below, the outer wall is fixedly connected to the rib plate 4, and the rib plate is connected to the reaction zone Cylinder wall 12, the inner chamber of described reaction zone cylinder wall forms reaction zone 14, and described reaction zone is communicated with water inlet feed pipe 1 and Mg 2+ Dosing pipe 2, a stirring device is provided in the reaction zone, a mud hopper 7 is connected under the wall of the sedimentation zone, and a mud discharge pipe 9 is connecte...

Embodiment 2

[0018] In the equipment for treating industrial wastewater by the crystallization method, the stirring device includes a stirrer 10, the stirrer is connected to the stirring paddle 13, and the stirrer is installed on the rib plate through the stirrer bracket 11 .

Embodiment 3

[0020] In the equipment for treating industrial waste water by the crystallization method, there is an energy-dissipating plate 15 under the wall of the reaction zone, and the energy-dissipating plate has energy-dissipating holes 16 . It can effectively weaken the convection and vortex effect produced by the effluent in the reaction zone, and ensure the precipitation effect in the precipitation zone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com