Processing technology of bitter salt water

A technology for treating brackish water, which is applied in the field of brackish water treatment and brackish water, can solve the problems of membrane pollution, low recovery rate, and high cost, and achieve the goal of reducing costs, increasing recovery rate, and reducing operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

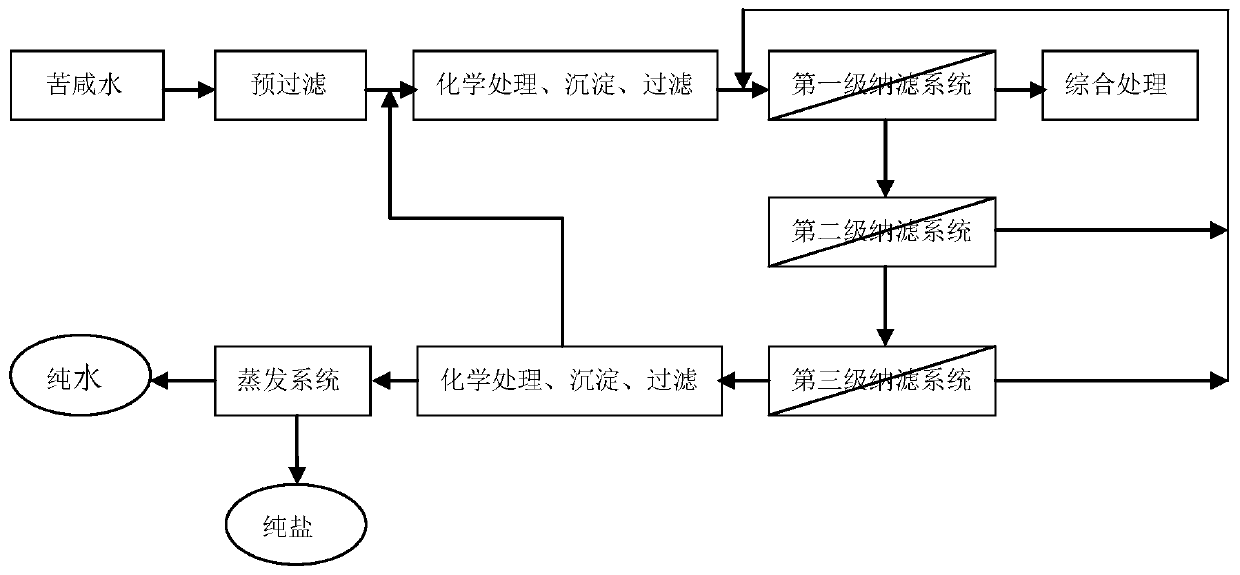

[0024] Such as figure 1 As shown, adopting the brackish water treatment process provided by the present invention to process the brackish water with a calcium content greater than 10g / L, a pH value of 7.5, a salt content greater than 100g / L, and a manganese and aluminum content greater than 500ppb, specifically includes the following step:

[0025] (1) Use microfiltration or ultrafiltration system for pre-filtration, the material of the filter membrane used is polysulfone, polyether peak or polyvinylidene fluoride, the feeding pressure is less than 10bar, and the recovery rate of water is higher than 90%, which can Filter out particles with a particle size of 0.01-0.1 μm, used to separate and reduce the content of suspended solids in brackish water, and the turbidity of pre-filtered brackish water is <1NTU;

[0026] (2) Add 1% NaOH to the brackish water after pre-filtration to control the pH to 10-10.5, and use the sludge obtained from the chemical reaction of the third-stage...

Embodiment 2

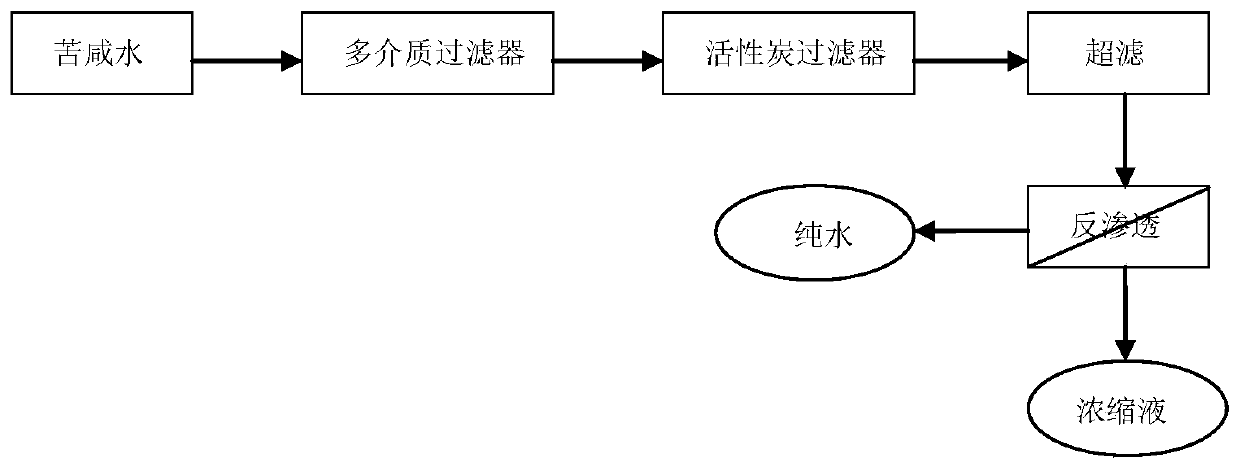

[0032] Such as figure 2 Shown is the process flow chart of the traditional process for treating brackish water. As shown in the figure, first use multimedia filtration to remove the turbidity in the water, reduce the turbidity in the water to below 3NTU, and then use activated carbon filter, activated carbon filter Remove odor, organic matter, colloid, iron and residual chlorine in the water, and then use ultrafiltration. The ultrafiltration pore is less than 0.01 micron, which can completely filter out bacteria, rust, colloid and other harmful substances in the water, and retain the original trace elements in the water. and minerals. Afterwards, a reverse osmosis membrane is used to generate permeate and concentrate. The permeate is the clean water of the product, and the concentrate is drained (the problem of concentrate treatment will arise). This technique can handle common brackish water, but when being used for processing the special brackish water mentioned in the pre...

Embodiment 3

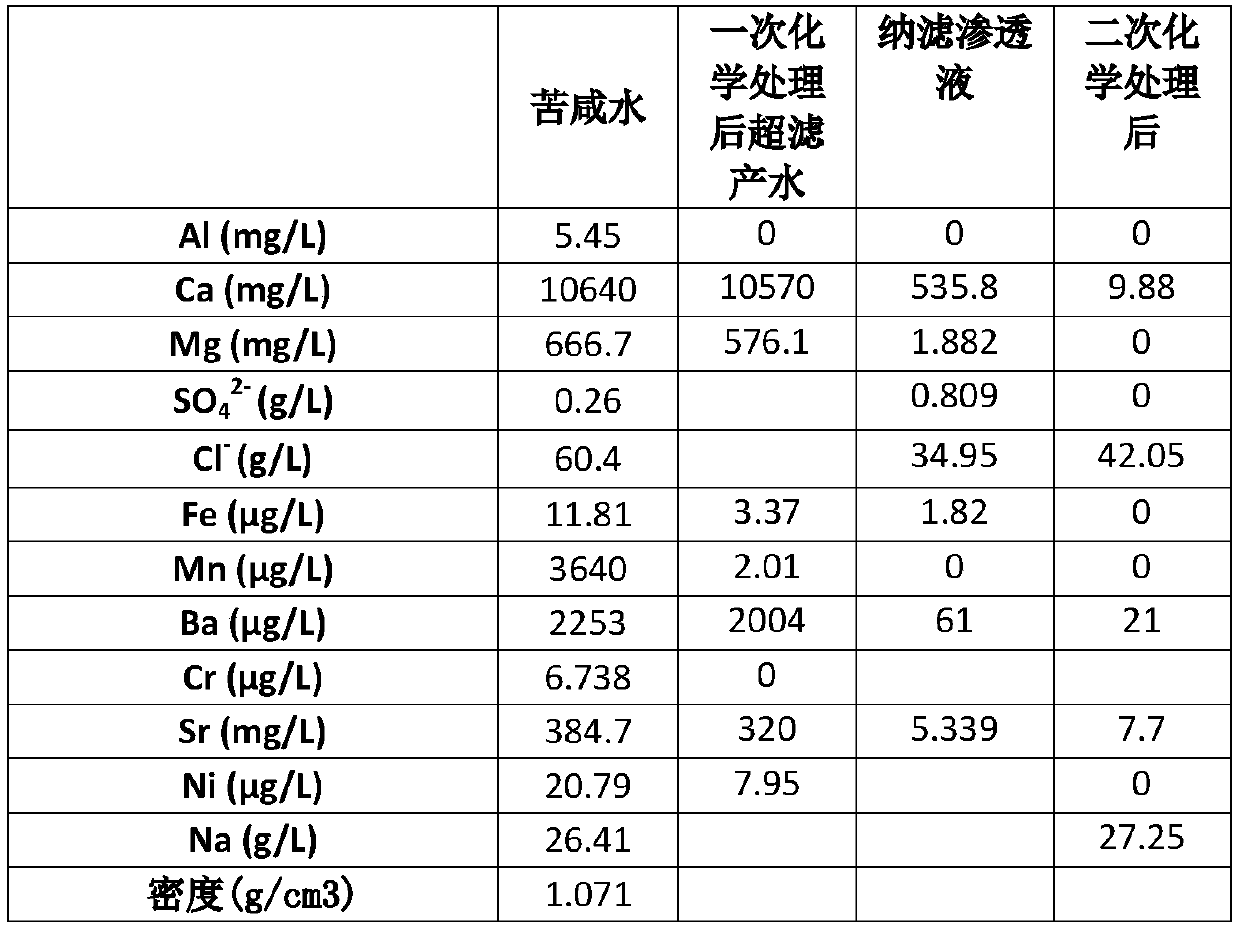

[0034] Adopt the brackish water treatment technology provided by the present invention to process brackish water, the brackish water water quality is specifically shown in the raw water quality in Table 1, specifically comprises the following steps:

[0035] (1) The microfiltration system is used for pre-filtration, the material of the membrane used is polysulfone, the feeding pressure is less than 10 bar, the recovery rate of water is higher than 90%, and it can filter out particles with a particle size of 0.01-0.1 μm. Pre-filtration After the brackish water turbidity <1NTU;

[0036] (2) Add 1% NaOH to the brackish water after pre-filtration to control the pH to 10-10.5, and use the sludge obtained from the chemical reaction of the third-stage nanofiltration concentrate in the back-end process to carry out precipitation and adsorption under alkaline conditions , remove the manganese and aluminum precipitates in the water, and then filter with an ultrafiltration system. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com