Method for preparing potassium sodium niobate functional ceramic film on glass base surface by using laser

A glass matrix, potassium sodium niobate technology, applied in the field of functional ceramics preparation, electronic functional ceramics preparation, can solve the complex process, parameters such as film size and shape can not be controlled, difficult and high vacuum preparation conditions and other problems, to achieve repeatability The effect of high film thickness, shape and size controllability, and short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

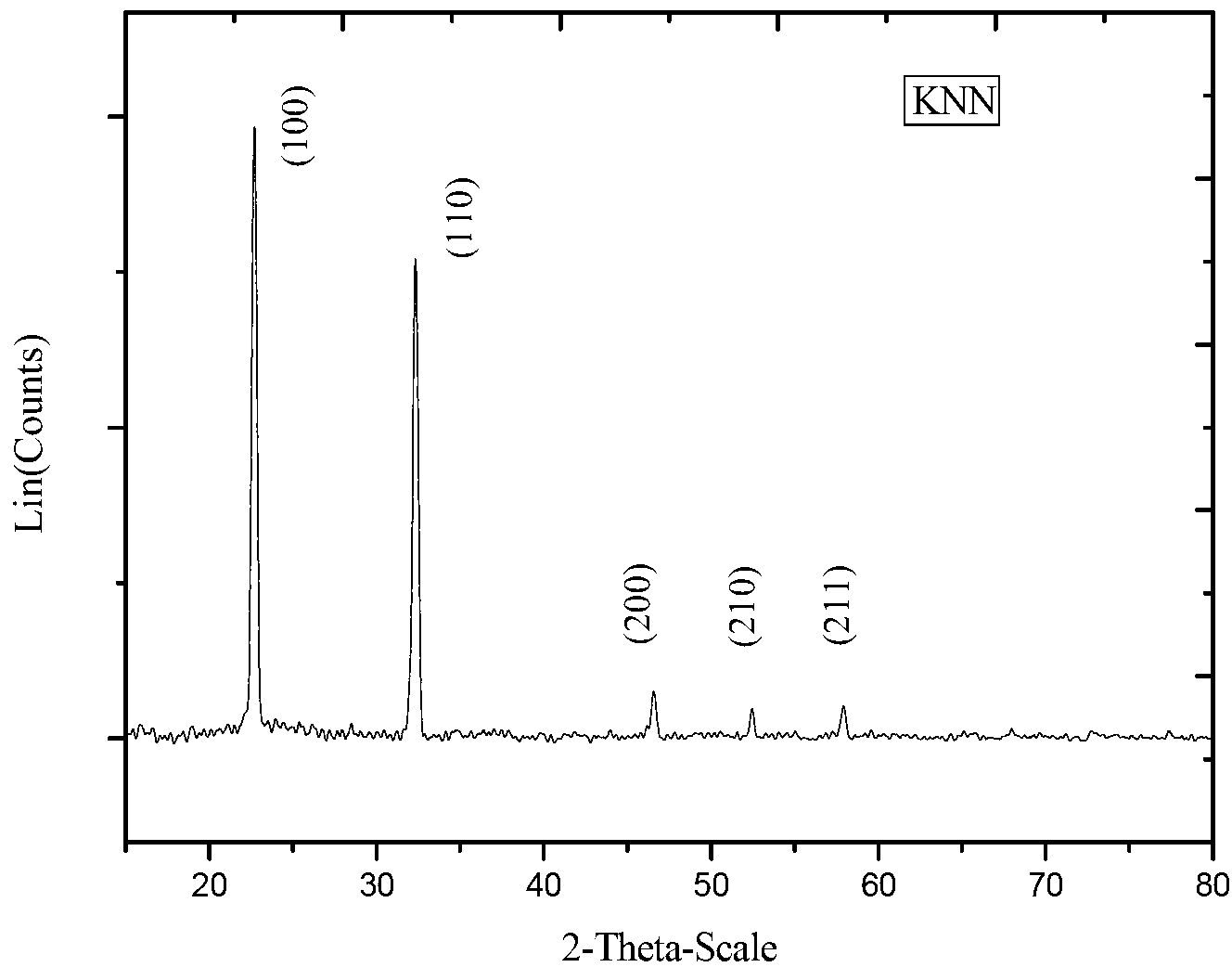

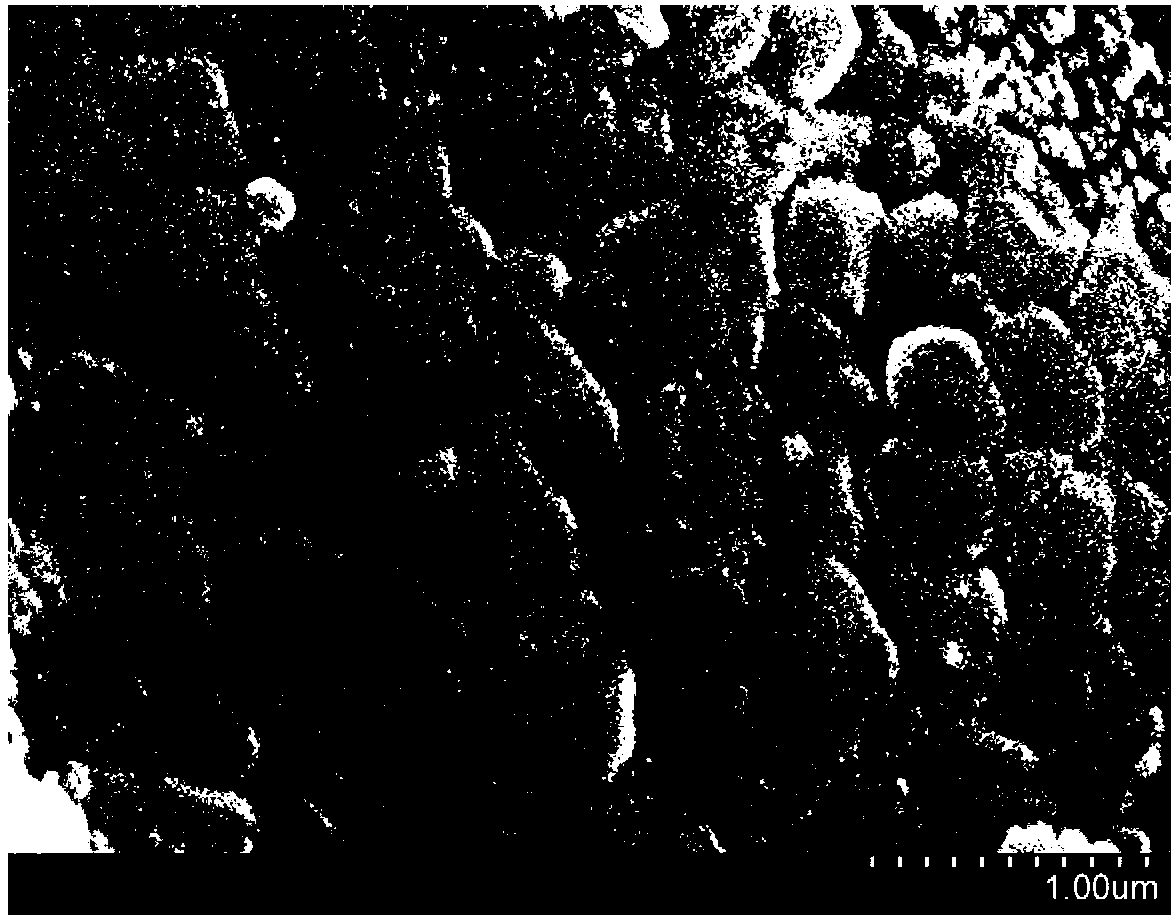

[0024] Press Na 0.5 K 0.5 NbO 3 The molar stoichiometric ratio of Na, K, and Nb in Na, K, and Nb is 0.5:0.5:1 to weigh Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 The raw materials are poured into a ball mill jar with anhydrous ethanol at a volume ratio of 1:1 and ball milled for 8 hours. The mixed powder obtained by drying the obtained slurry is sieved and pressed into a block. The obtained mixture is pre-fired at 800° C. for two hours, and the obtained potassium sodium niobate block raw material is ball milled again, dried, and sieved to obtain potassium sodium niobate powder. Add potassium sodium niobate powder to 6% mass ratio of PVA and mix it evenly on the surface of ordinary transparent glass substrate. Draw a 5mm*5mm rectangle in the laser control software. Select a 20W fiber pulse laser, scan the powder on the glass substrate directly at a speed of about 300mm / s, a scanning frequency of 80KHz, a pulse width of 10ns, and adjust the focus position. After cooling at room t...

example 2

[0026] Press Na 0.5 K 0.5 NbO 3 The molar stoichiometric ratio of Na, K, and Nb in Na, K, and Nb is 0.5:0.5:1 to weigh NaNO 3 、KNO 3 , Nb 2 o 5 The raw materials are poured into a ball mill jar with anhydrous ethanol at a volume ratio of 1:1 and ball milled for 8 hours. The mixed powder obtained by drying the obtained slurry is sieved and pressed into a block. The obtained mixture is pre-fired at 800° C. for two hours, and the obtained potassium sodium niobate block raw material is ball milled again, dried, and sieved to obtain potassium sodium niobate powder. Add potassium sodium niobate powder to 6% mass ratio of PVA and mix it evenly on the surface of K9 glass substrate. Draw a circular graph of φ5mm in the laser control software. Select a 20W fiber pulse laser to directly scan the powder on the glass substrate at a speed of about 300mm / s and adjust the focus position. After cooling at room temperature, the desired functional ceramic film is obtained.

example 3

[0028] Press Na 0.5 K 0.5 NbO 3 The molar stoichiometric ratio of Na, K, and Nb in Na, K, and Nb is 0.5:0.5:1 to weigh Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 The raw materials are poured into a ball mill jar with anhydrous ethanol at a volume ratio of 1:1 and ball milled for 8 hours. The mixed powder obtained by drying the obtained slurry is sieved and pressed into a block. The obtained mixture is pre-fired at 800° C. for two hours, and the obtained potassium sodium niobate block raw material is ball milled again, dried, and sieved to obtain potassium sodium niobate powder. The sodium potassium niobate powder is added to 6% by mass of PVA and mixed evenly on the surface of the quartz glass substrate. Draw a 10*2mm line graph in the laser control software. Select a 50W carbon dioxide laser, scan the powder on the glass substrate directly at a speed of about 120mm / s, a scanning frequency of 80KHz, a pulse width of 10ns, and adjust the focus position. After cooling at room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com