Binary compound oil-flooding composition and application thereof in tertiary oil recovery

A binary compound flooding and composition technology, which is applied in the direction of drilling composition, production fluid, earthwork drilling and production, etc., can solve the problems of being unable to meet the needs of oil displacement operations, failing to achieve ultra-low interfacial tension, and interfacial tension recovery. , to achieve good emulsification performance, low interfacial tension and good interfacial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

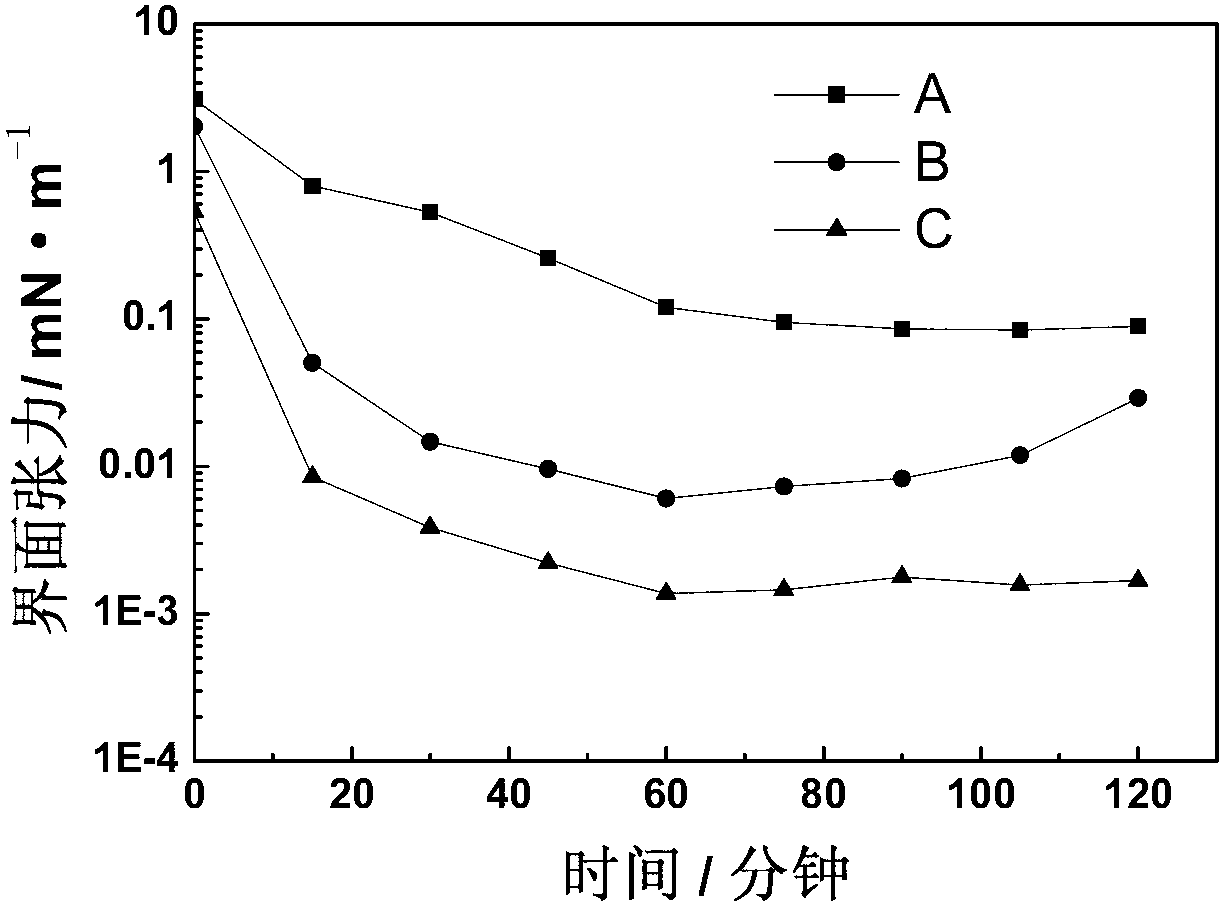

[0033] Embodiment 1 interface performance research

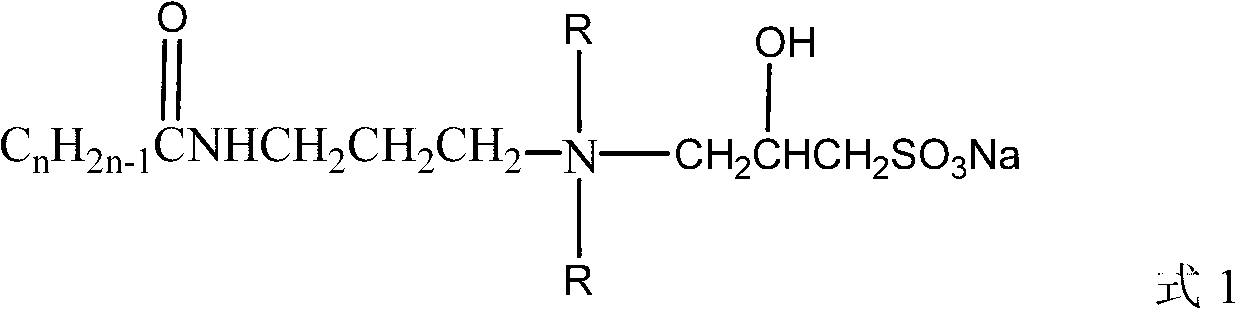

[0034] In this example, the composition for oil displacement using carbon tetradecyl dimethyl hydroxysultaine and erucic acid amido hydroxysultaine as surfactants and the use of erucic acid amido hydroxysultaine The interfacial properties of the binary composite oil flooding composition with carbon tetradecyl dimethyl hydroxy sultaine and carbon tetradecyl dimethyl hydroxy sultaine were studied, wherein the above-mentioned erucic acid amido hydroxy sultaine and carbon fourteen The structure of alkyl dimethyl sulfobetaine is as follows respectively (the hydroxysulfobetaine of the following examples is identical with the hydroxysulfobetaine here):

[0035] Erucic acid amido sulfobetaine:

[0036]

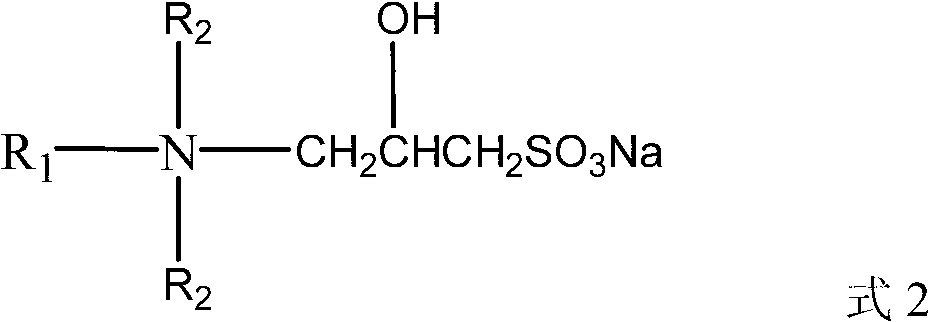

[0037] Carbon Tetradecyl Dimethyl Hydroxysultaine:

[0038]

[0039] experiment method:

[0040] Adopting the formation water whose salinity is 84000mg / L to prepare carbon tetradecyl dimethyl sulfobetaine and star-shaped te...

Embodiment 2

[0045] The proportioning optimization of embodiment 2 composite surfactants

[0046] In this example, the interfacial properties of the composite surfactant composed of erucic acid amido sulfobetaine and carbotetradecyldimethyl sulfobetaine were studied. The above composite surfactant is erucic acid amido sulfobetaine and carbotetradecyl dimethyl sulfobetaine in different mass ratios.

[0047] Test method: Formation water with a salinity of 84000mg / L and a composite surfactant were used to prepare a solution with a composite surfactant concentration of 0.2wt%, without adding polymers; the solution was tested by the spinning drop method using a TX500C interfacial tension tester The interfacial tension, the test temperature is 80 ℃, the rotation speed is 5000RPM, the results are shown in Table 1.

[0048] As can be seen from Table 1, within the ratio range listed, the solution using composite surfactants can reach ultra-low interfacial tension; When methyl sulfobetaine=6:4, th...

Embodiment 3

[0051] Embodiment 3 emulsification performance test

[0052] In this example, the emulsification performance of the binary composite oil flooding composition using a composite surfactant was tested. Wherein, in the above composite surfactant, the mass ratio of erucic acid amido sulfobetaine to carbotetradecyl dimethyl sulfobetaine is 6:4.

[0053] Test method: Formation water with a salinity of 84000mg / L and complex surfactants were used to prepare 50mL of complex surfactant solutions with different concentrations, without adding polymers;

[0054] According to the oil-water ratio of 1:1, crude oil (under the conditions of 95°C and 21.4MPa, the viscosity of crude oil is 0.85mPa·s; the saturated hydrocarbon content is 52%, and the aromatic hydrocarbon content is 43%) is mixed with the above-mentioned composite surfactant solution, poured into in a sealed bottle;

[0055] HZ-8812S water bath reciprocating constant temperature oscillator was used to vibrate at a speed of 90rpm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com