Bacillus sp. UTM03 and application thereof

A technology of UTM03 and Bacillus, applied in the field of environmental microorganisms, can solve the problems of increasing the workload and cost of sludge composting, lack of effective thermophilic microbial populations, and ignoring excellent conditioners, so as to reduce the cost of composting, improve economic benefits and social Benefit, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

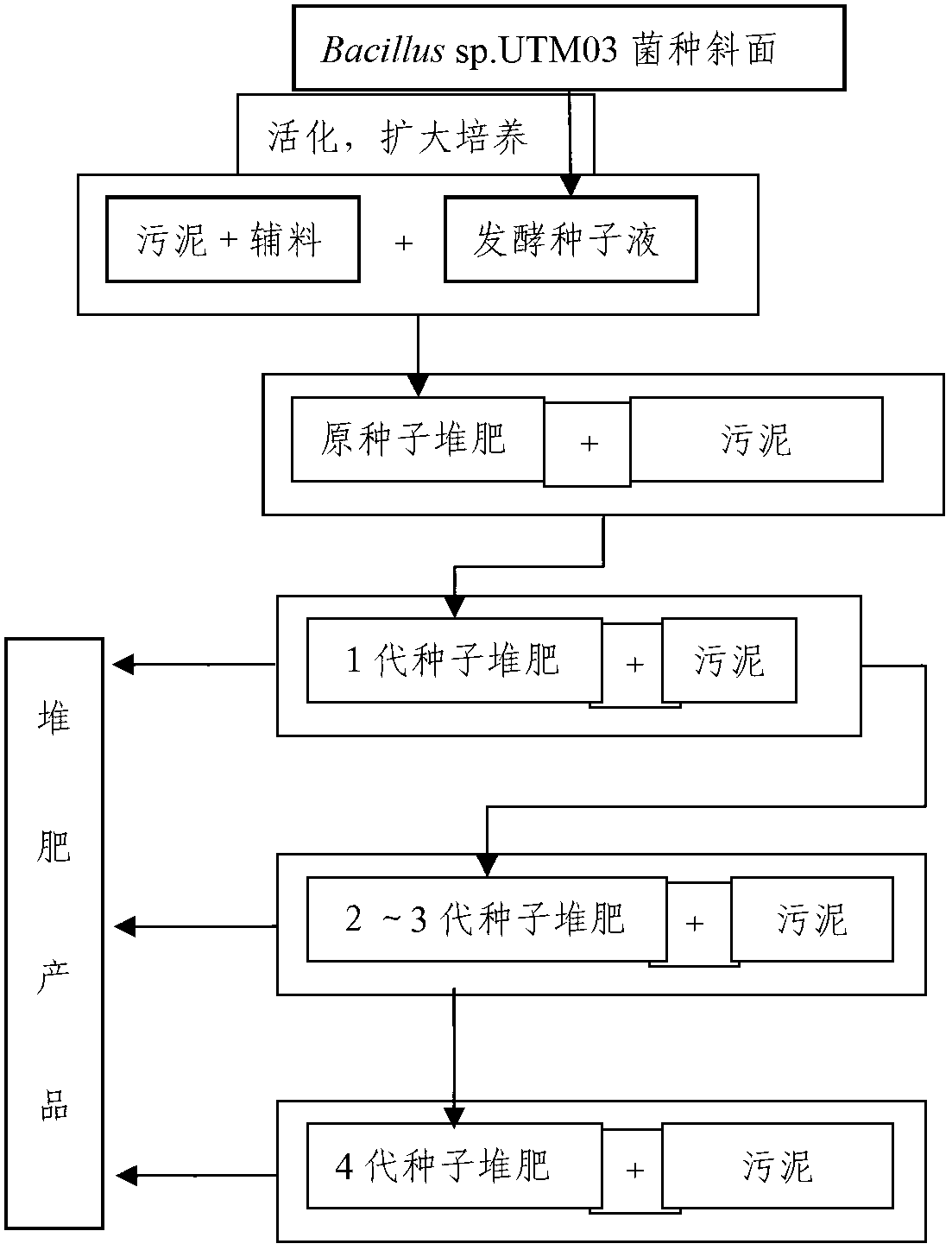

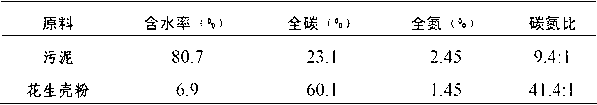

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Isolation and Identification of Bacillus UTM03

[0029] In a sterile environment, weigh 5g of the sludge compost sample into a 50ml sterile water triangular flask equipped with 10 glass beads, place it on a shaker and vibrate at 160r / min for 30 minutes to fully disperse the sample, and then place it for 70 ℃, static culture for 12 hours.

[0030] Take out the above-mentioned triangular flask for static culture, and let it stand for 3 minutes in a sterile environment, then use a sterile straw to draw 5ml of supernatant and add it to 50ml of sterilized bacterial culture solution, shake well, and place At 70° C., static enrichment culture was carried out for 48 hours, and thus subcultured for 4 generations. The formula of the bacterial liquid medium is: 0.5 g of beef extract, 1 g of peptone, 0.5 g of sodium chloride, 100 ml of distilled water, pH 7.2-7.4, and sterilized at 121° C. for 20 minutes.

[0031] Take out the enrichment culture flask of the above 4 gen...

Embodiment 2

[0035] Example 2 Preparation of Fermented Seed Liquid

[0036] Take the slant of the bacterial strain Bacillus sp.UTM03 of the present invention and activate and cultivate it at 70°C for 8 hours, then inoculate it into a shaker flask filled with sterilized LB culture solution, place it on a water bath constant temperature oscillator for primary expansion, and the oscillation frequency 160rpm, time 36 hours, temperature 70°C, culture solution OD was tested 600 It is 2.523; take the primary culture liquid and carry out expansion cultivation in the fermenter, control the temperature at 65 ° C, stir for 15 minutes at intervals of 6 hours, rotate at 150 rpm, ventilate for 15 minutes at intervals of 6 hours, and the ventilation rate is 1: 1.2 (V / V). After 3 days, detect the OD of the fermentation broth 600 It is 3.003, which is the fermented seed liquid.

Embodiment 3

[0037] Example 3 Preparation of Fermented Seed Liquid

[0038] Take the culture slant of the bacterial strain Bacillus sp.UTM03 of the present invention and activate it at 65°C for 12 hours, then inoculate it into a shaker flask filled with sterilized LB culture solution, place it on a water-bath constant temperature oscillator for primary expansion, and the oscillation frequency 180rpm, time 36 hours, temperature 65°C, the OD600 of the culture medium was detected to be 2.815; take the first-grade culture medium and expand it in the fermenter, control the temperature at 65°C, stir for 10 minutes at intervals of 4 hours, and stir at 160rpm at intervals of 4 hours Ventilate for 10 minutes, and the ventilation rate is 1:0.8 (V / V). After 4 days of fermentation, the OD600 of the fermented liquid is detected to be 3.103, which is the fermented seed liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com