Cellulose immobilized cis epoxy succinic acid hydrolase and method for preparing tartaric acid

A technology of epoxy succinic acid and cellulose, applied in the field of bioengineering, can solve the problems affecting the separation and purification of the final reaction product and the final yield, poor enzyme stability, easy inactivation of enzymes, etc. , less impurities, the effect of improving the performance of the enzyme

- Summary

- Abstract

- Description

- Claims

- Application Information

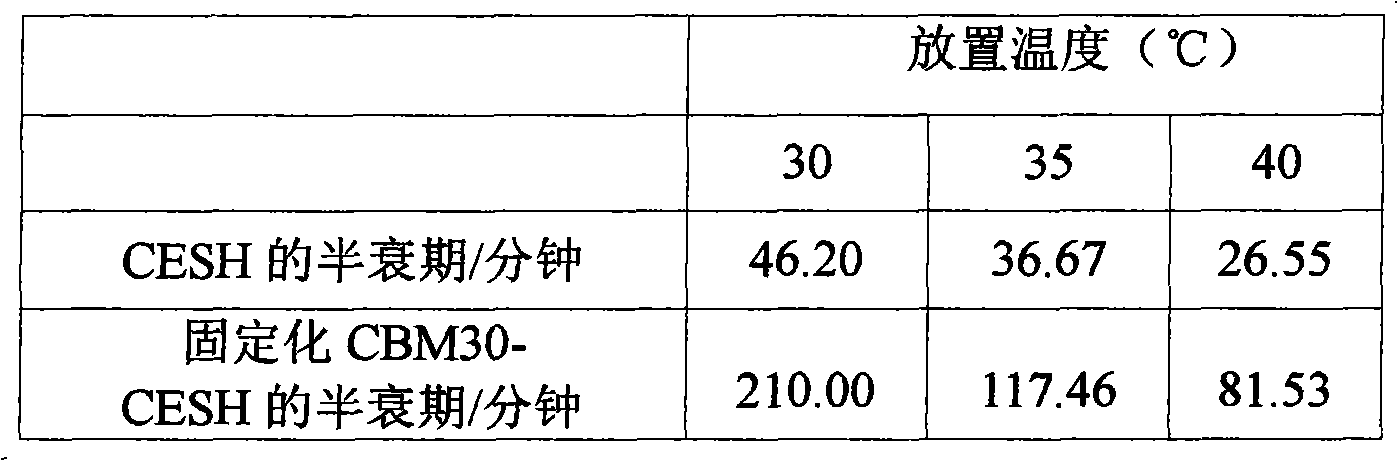

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Cellulose-immobilized L-type cis-epoxysuccinate hydrolase

[0020] (1) Fusing the carbohydrate binding module CBM30 at the N-terminal or C-terminal of the gene encoding cis-epoxysuccinate hydrolase to obtain a fusion expression vector;

[0021] (2) Pick a single colony transformed with the recombinant plasmid on the plate, insert it into the culture medium containing ampicillin, cultivate it at 37°C until the OD600 reaches 0.8-1.0, add IPTG to the final concentration of 0.2mM, and then transfer it to a constant temperature shaker at 25°C The induction culture was continued for 8 hours. The bacterial liquid was centrifuged at 4°C and 8000 rpm for 15 minutes to collect the bacterial cells.

[0022] (3) Wash the target cells with 40ml of phosphate buffer with a pH of 7.4, remove the residual medium solution, resuspend the cells with 20ml of phosphate buffer, and break the resuspended cells under a pressure of 22000psi with a high-pressure cell disruptor. wall, the bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com