Double-tower constant-melting-rate protective atmosphere electro slag furnace available for three-station alternate smelting

A technology of tower structure and protective atmosphere, which is applied in the field of special metallurgical equipment, can solve the problems of inability to implement effective control, inability to control startup and feeding, and inability to control melting rate, so as to improve the control accuracy of constant melting rate and improve the effective Effects of Utilization and Level Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

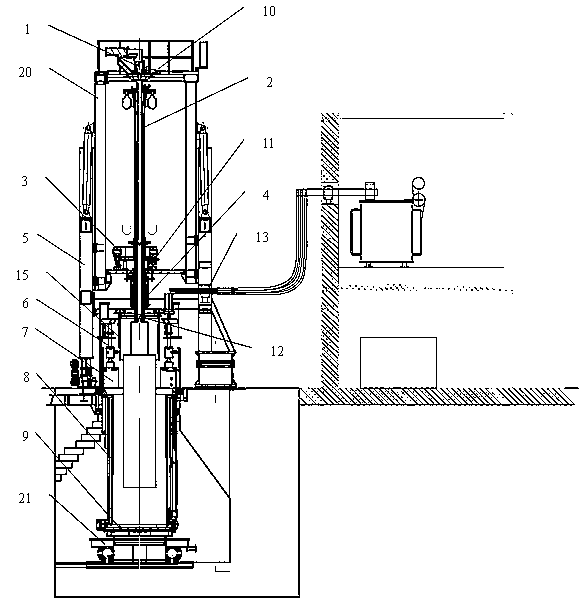

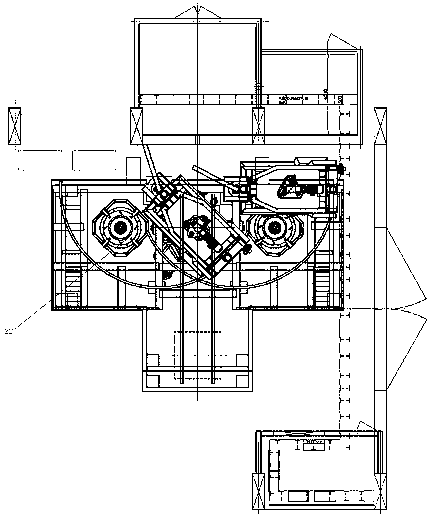

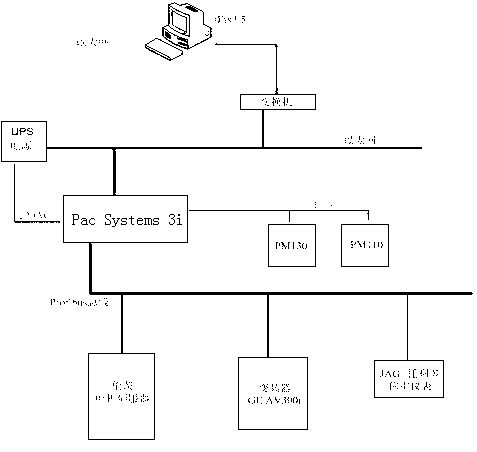

[0012] control attached figure 1 , 2 , its structure includes two rotatable tower furnace heads, a mobile smelting station, two auxiliary stations and an electrical system and PLC plus computer control system, two rotatable furnace heads are located in a mobile smelting station and Between the two auxiliary stations; the main circuits of the melting power supply of the two rotatable tower furnace heads are respectively positioned on a mobile melting station, and the positioning is through four coaxial positioning cylinders on the upper part of the crystallizer electrode The end of the cylinder piston rod in the positioning cylinder is connected with the coaxial return circuit of the electroslag power supply, and the four cylinder piston rods are inserted into the four columns at the bottom of the crystallizer electrode.

[0013] The secondary side short net of the transformer in the electrical system part is fixed on the secondary short net connection fixing frame 13 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com