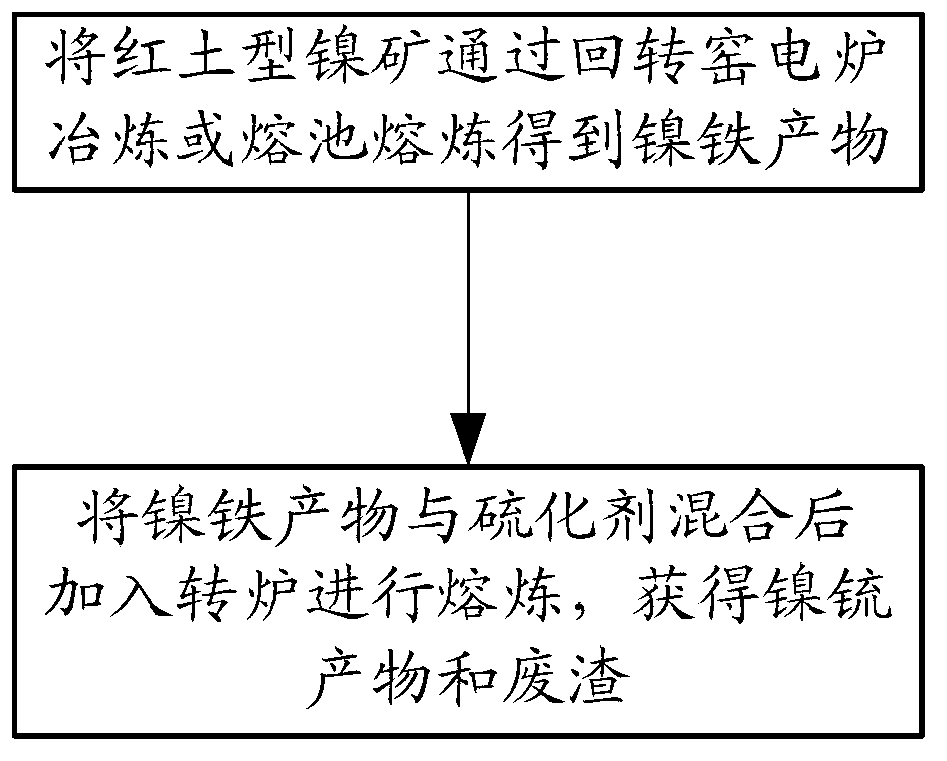

Method for smelting nickel matte by laterite type nickel ore

A technology of laterite-type nickel ore and nickel matte, applied in the direction of nickel sulfide, etc., can solve the problems of difficult and harsh utilization of laterite resources, and achieve the effect of reducing energy consumption and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0149] Provide laterite-type nickel ore, put it into a drying kiln for calcination and drying at 700°C to obtain dry laterite-type nickel ore, mix the dried laterite-type nickel ore, anthracite and limestone in a mass ratio of 16:3:1 to obtain a mixed material, The mixed material is added to a top-blown melting furnace, and the top-blown molten pool is smelted at 1500° C. to obtain ferronickel products and waste slag.

[0150] Sulfur and limestone are added to the ferronickel product during discharge into the converter, the mass ratio of ferronickel product: sulfur: limestone is controlled to be 10:1:1, and the melting temperature of the converter is 1450°C to obtain the nickel matte product Ni x Fe 1-x S, Ni 3 S 2 And NiFe mixture, waste residue and hot flue gas.

[0151] The hot flue gas is subjected to dust collection treatment, and the waste heat of the hot flue gas is used for power generation.

[0152] The discharge temperature of the waste slag is 1400° C., and the ...

Embodiment 2

[0154] Provide laterite-type nickel ore, put it into a drying kiln for calcination and drying at 700°C to obtain dry laterite-type nickel ore, mix dry laterite-type nickel ore, anthracite and limestone at a mass ratio of 15:2:3 to obtain a mixed material, The mixed material is put into a side-blown melting furnace, and the side-blown molten pool is smelted at 1500° C. to obtain ferronickel products and waste slag.

[0155] Sulfur and limestone are added to the ferronickel product when it is discharged into the converter, the mass ratio of ferronickel product: sulfur: limestone is controlled to be 10:1:1, and the melting temperature of the converter is 1500°C to obtain the nickel matte product Ni x Fe 1-x S, Ni 3 S 2 And NiFe mixture, waste residue and hot flue gas.

[0156] The hot flue gas is subjected to dust collection treatment, and the waste heat of the hot flue gas is used for power generation.

[0157] The discharge temperature of the waste slag is 1300°C, and the w...

Embodiment 3

[0159] Provide laterite-type nickel ore, put it into a drying kiln for calcination and drying at 700°C to obtain dry laterite-type nickel ore, mix the dried laterite-type nickel ore, anthracite and limestone in a mass ratio of 16:3:1 to obtain a mixed material, Putting the mixed material into a roasting rotary kiln for roasting to obtain calcined sand; adding the calcined sand to an electric furnace for smelting to obtain ferronickel products and waste slag.

[0160] Sulfur and limestone are added to the ferronickel product when it is discharged into the converter, the mass ratio of ferronickel product: sulfur: limestone is controlled to be 10:1:1, and the melting temperature of the converter is 1500°C to obtain the nickel matte product Ni x Fe1-x S, Ni 3 S 2 And NiFe mixture, waste residue and hot flue gas.

[0161] The hot flue gas is subjected to dust collection treatment, and the waste heat of the hot flue gas is used for power generation.

[0162] The discharge tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com