Flexible organic electroluminescence display (OELD) and manufacture method thereof

A production method and electroluminescence technology, which are applied in the direction of electric solid device, semiconductor/solid state device manufacturing, circuits, etc., can solve the problems of poor temperature resistance, high roughness, and short life of OLED of plastic films, and achieve strong conductivity and flexibility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

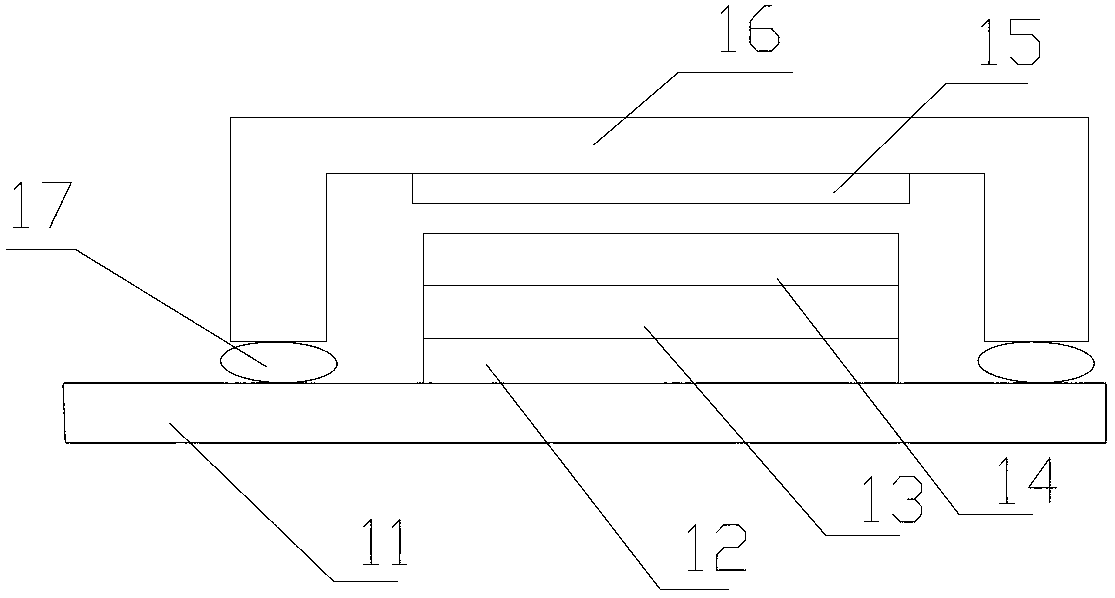

[0042] The method in this embodiment is used to fabricate a flexible OLED with a top emission structure, and the driving mode is passive, that is, PMOLED. The method of this embodiment specifically includes the following steps:

[0043] 1. Take an FPC base material, cut the FPC base material into an appropriate size, and clean it;

[0044] 2. Spin-coat photoresist on the second Cu layer 33, and perform exposure after pre-curing. The exposure pattern is designed according to the PMOLED electrode pattern; after development and main curing, put it into an acidic solution for acid etching, and the acid etching time depends on the thickness of the Cu layer and change; after stripping, the required first electrode pattern is obtained;

[0045] 3. Make an insulating protective layer and a cathode spacer post pattern on the first electrode pattern. This process is the same as the traditional PMOLED manufacturing process, so it will not be repeated here; through this step, a flexible ...

Embodiment 2

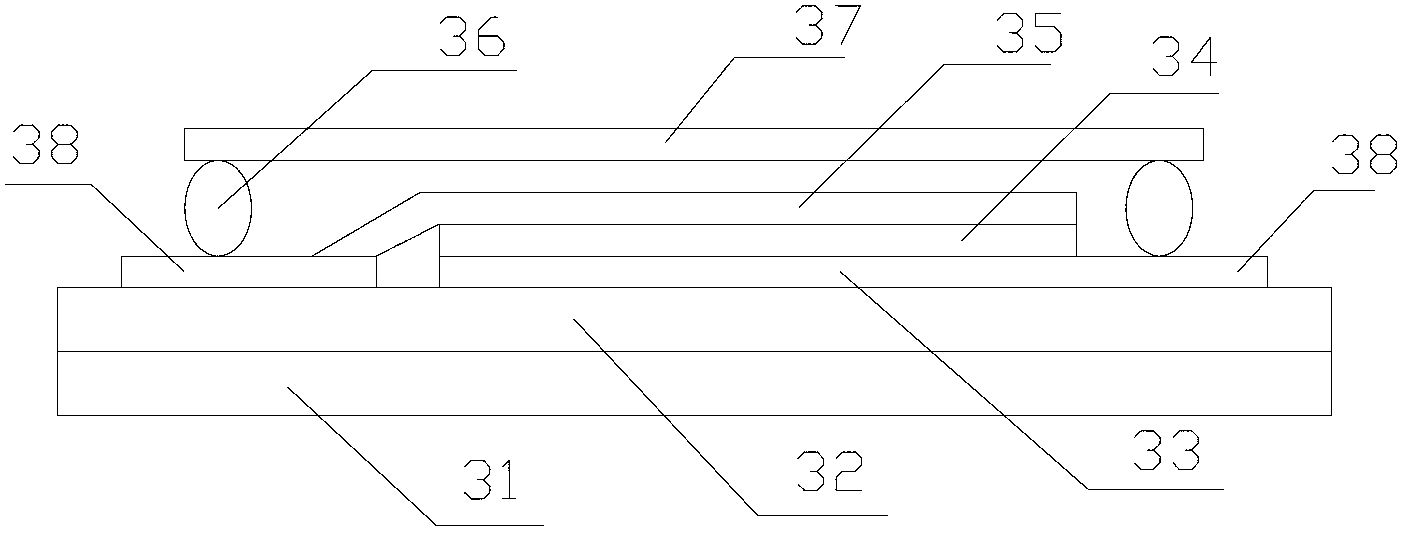

[0051] The method in this embodiment is used to fabricate a flexible OLED with a top emission structure, and the driving mode is active, that is, AMOLED.

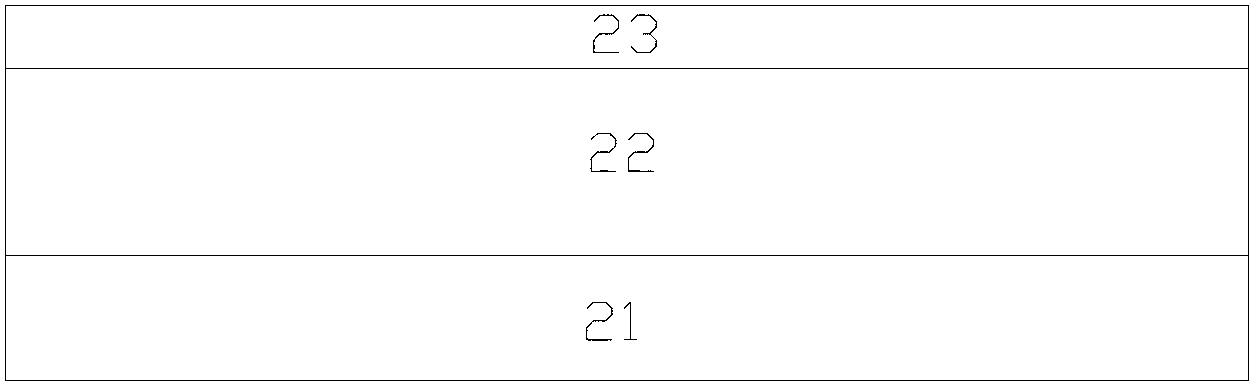

[0052] 1. Take an FPC substrate, cut it into an appropriate size, and clean it. FPC structure such as figure 2 , including a first Cu layer, a PI layer and a second Cu layer;

[0053] 2. Spin-coat photoresist on the second Cu layer, and perform exposure after pre-curing. The exposure pattern is designed according to the AMOLED first electrode pattern; after developing and main curing, put it into an acidic solution for acid etching. The acid etching time is obtained according to the Cu layer. The thickness varies; after stripping, the required first electrode pattern is obtained;

[0054] 3. Fabricate a TFT drive circuit on the first electrode pattern, the process is the same as the traditional AMOLED TFT substrate production process, and will not be repeated here; through this step, the TFT substrate is obtained;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com