High-hydrogen-storage-capacity lithium borohydride/graphene (LiBH4/RGO) composite hydrogen storage material and preparation method thereof

A hydrogen storage material and technology for hydrogen storage, applied in the production of hydrogen and other directions, can solve the problem of high hydrogen desorption temperature and achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

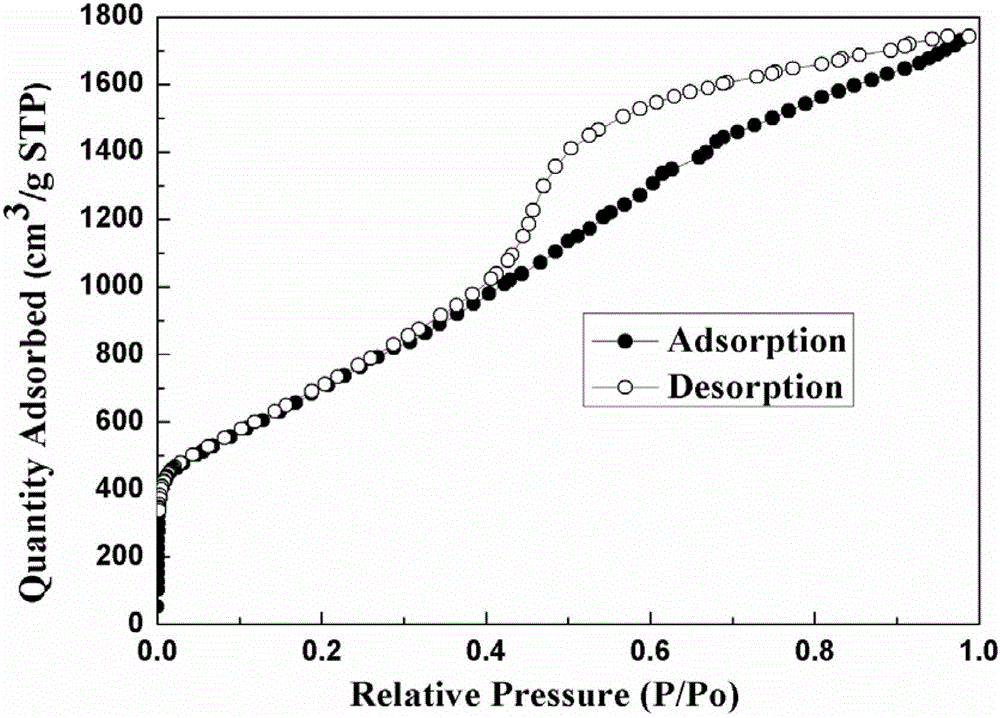

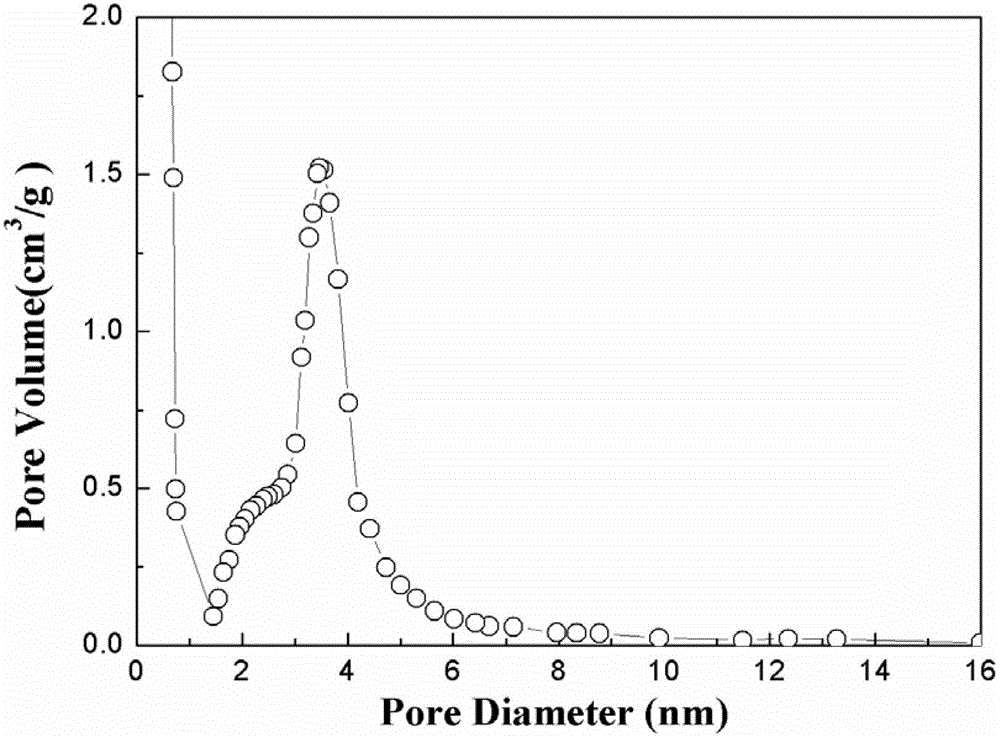

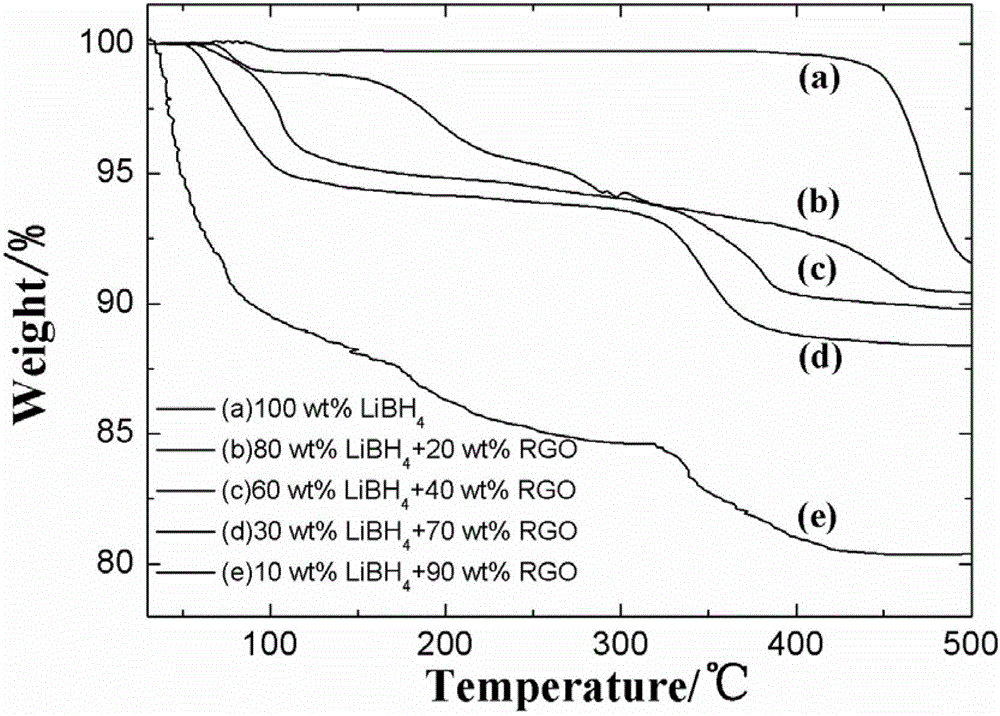

[0024] A LiBH 4 / RGO high hydrogen storage capacity composite hydrogen storage material, including 30wt% LiBH 4 material and 70wt% RGO material, the surface of RGO material has dense pores, LiBH 4 The material is evenly dispersed in the pores of the RGO material. RGO is prepared by a chemical redox method. RGO has a pore size of 2~10nm and a 2540m 2 / g specific surface area.

[0025] The aforementioned LiBH 4 Preparation method of RGO composite hydrogen storage material with high hydrogen storage capacity:

[0026] 1) Synthesized graphene (RGO) with controllable pore size and specific surface area by chemical redox method

[0027] Graphite oxide (GO) was prepared by a modified Hummers method. First weigh 0.5g graphite, 0.25gKNO 3 , placed in a 500mL three-neck flask, add 12mL concentrated H 2 SO 4 , and magnetically stirred for 30 min in an ice-bath environment. Then slowly add 1.5g KMnO 4 , stirred at 35°C for 24h, then slowly added 150mLH 2 O, stirred for 12h. ...

Embodiment 2

[0036] A LiBH 4 / RGO high hydrogen storage capacity composite hydrogen storage materials, including 30wt% LiBH 4 material and 70wt% RGO material, the surface of RGO material has dense pores, LiBH 4 The material is evenly dispersed in the pores of the RGO material. RGO is prepared by a chemical redox method. RGO has a pore size of 2~10nm, and 2540m 2 / g specific surface area.

[0037] The aforementioned LiBH 4 Preparation method of RGO composite hydrogen storage material with high hydrogen storage capacity:

[0038] 1) The preparation method of RGO is the same as in Example 1

[0039] 2) Preparation of RGO-doped LiBH by high-speed ball milling 4

[0040] Under the protection of argon atmosphere and anhydrous and oxygen-free conditions, the mass ratio of RGO and LiBH was 70:30. 4 After mixing evenly (the amount of about 0.1g) was placed in a sealed ball mill jar, and mechanically ball milled at room temperature for 4.5h (planetary ball mill QM-1SP2). Wherein, the rotat...

Embodiment 3

[0042] A LiBH 4 / RGO high hydrogen storage capacity composite hydrogen storage materials, including 60wt% LiBH 4 material and 40wt% RGO material, the surface of RGO material has dense pores, LiBH 4 The material is evenly dispersed in the pores of the RGO material. RGO is prepared by a chemical redox method. RGO has a pore size of 2~10nm and a 2540m 2 / g specific surface area.

[0043] The aforementioned LiBH 4 Preparation method of RGO composite hydrogen storage material with high hydrogen storage capacity:

[0044] 1) The preparation method of RGO is the same as in Example 1

[0045] 2) Preparation of RGO-doped LiBH by melt infiltration method 4

[0046] Under the protection of argon atmosphere and anhydrous and oxygen-free conditions, the RGO and LiBH 4 Mix evenly according to the mass ratio of 40:60, place it in a stainless steel reactor, and then fill it with H with an initial pressure of 100atm 2 , and then according to LiBH 4 The theoretical melting point is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com