Method for preparing inverted-growth wide-spectrum absorption III-V multi-junction cell

A III-V, multi-junction cell technology for use in solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

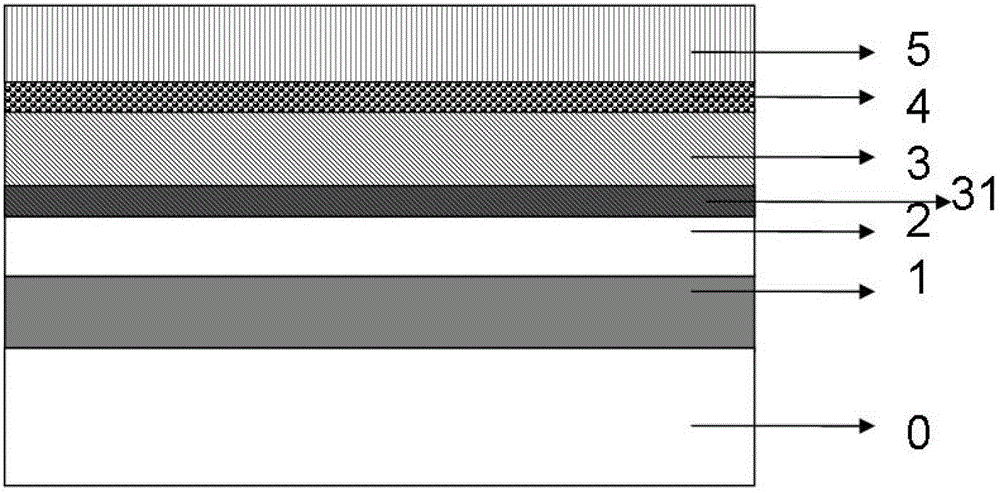

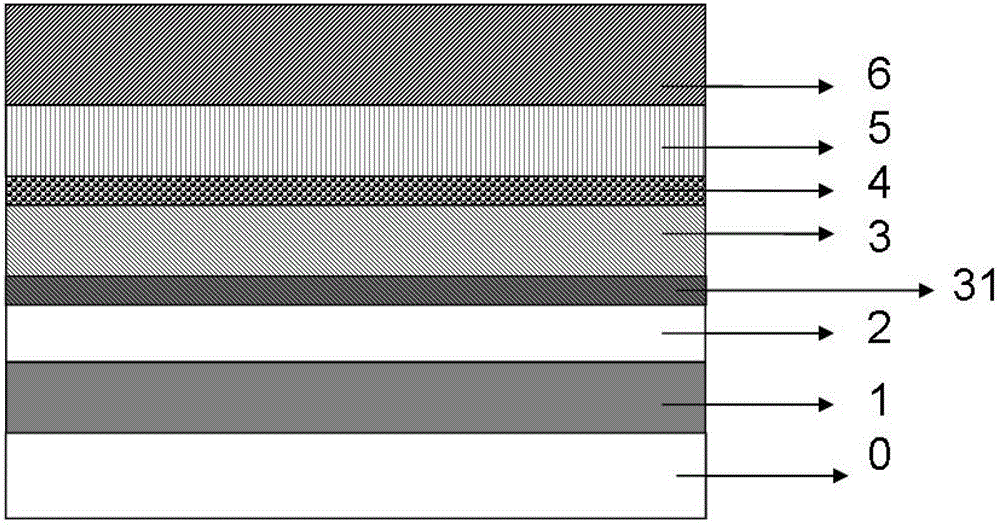

[0029] As mentioned above, in a nutshell, the present invention uses high aspect ratio dislocation trapping technology to realize InP epitaxy on GaAs materials (the lattice mismatch of the two reaches 3.81%, the thermal mismatch is small, and both are sphalerite Cubic structure, where GaAs thermal expansion coefficient 5.73*10 -6 ℃ -1 , InP thermal expansion coefficient 4.6*10 -6 ℃ -1 ), and the monolithic integration of GaAs and InP cells, and realize GaInP / GaAs / InGaAsP / InGaAs multi-junction cells on GaAs substrates by inversion growth, and then transfer them to With a cheaper substrate, a cost-effective solar cell with higher photoelectric conversion efficiency is obtained, and the preparation method is easy to implement, and can realize large-scale production of III-V multi-junction solar cells.

[0030] Further speaking, the technical scheme of the present invention is roughly as follows:

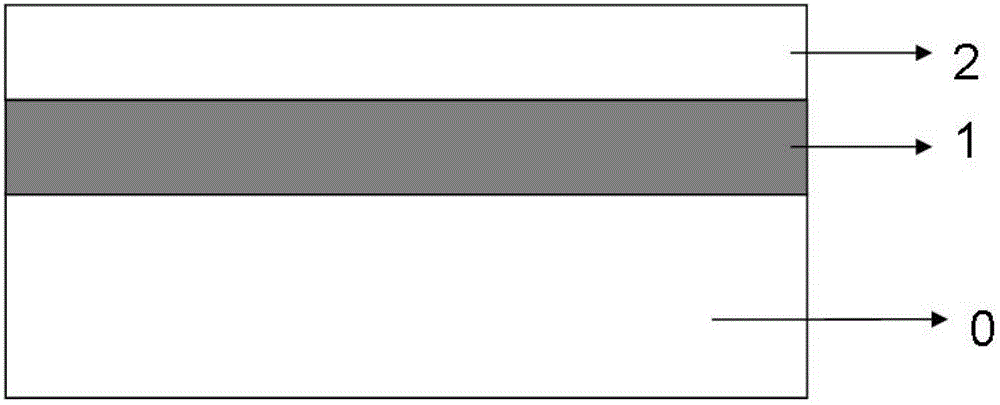

[0031]1) Use MOCVD or MBE to sequentially grow Al(Ga)As substrate peeling laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com