Ultra-fine microcrystalline cellulose talcum powder and preparation method of ultra-fine microcrystalline cellulose talcum powder

A crystalline cellulose and talcum powder technology, applied in the field of ultra-fine crystalline cellulose talcum powder, can solve the problems of poor skin smoothness and softness, low water absorption, unsuitable production, etc., and achieves high storage stability, good shape, The range of use and the effect of excellent use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

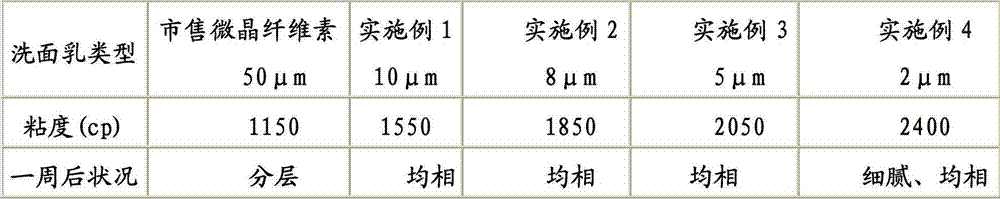

[0055] Embodiment 1: the preparation of ultrafine microcrystalline cellulose

[0056] 40 kg of commercially available microcrystalline cellulose with an average particle size of 50 μm was irradiated with Co-60 gamma rays at 50 kGy, and ultrafinely pulverized with a jet mill to obtain ultrafine microcrystalline cellulose with an average particle size of 10 μm.

Embodiment 2

[0057] Embodiment 2: the preparation of ultrafine microcrystalline cellulose

[0058] Mix 1 kg of the above-mentioned ultrafine microcrystalline cellulose with an average particle size of 10 μm and 5 kg of pure water, grind it with a wet mill for 30 minutes, and dry it in vacuum to obtain ultrafine microcrystalline cellulose with an average particle size of 8 μm .

Embodiment 3

[0059] Embodiment 3: the preparation of ultrafine microcrystalline cellulose

[0060] The ultrafine microcrystalline cellulose with an average particle size of 10 μm in Example 1 was mixed according to the following feeding ratio: 400 g of microcrystalline cellulose, 1440 mL of hydrochloric acid, 160 mL of sulfuric acid, and 2400 mL of purified water. React at 95°C for 24h. The obtained product is neutralized and washed with sodium hydroxide, finally centrifuged and spray-dried to obtain ultrafine microcrystalline cellulose with an average particle diameter of 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com