Pt nanparticle-supported MnO2 catalyst, its preparation method and application thereof

A nanoparticle and catalyst technology, which is applied in the field of MnO2 catalyst loaded with highly dispersed Pt nanoparticles and its preparation, can solve the problems of high equipment requirements, infrequent use, complicated preparation process, etc., and achieve low cost, simple operation, and advanced technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

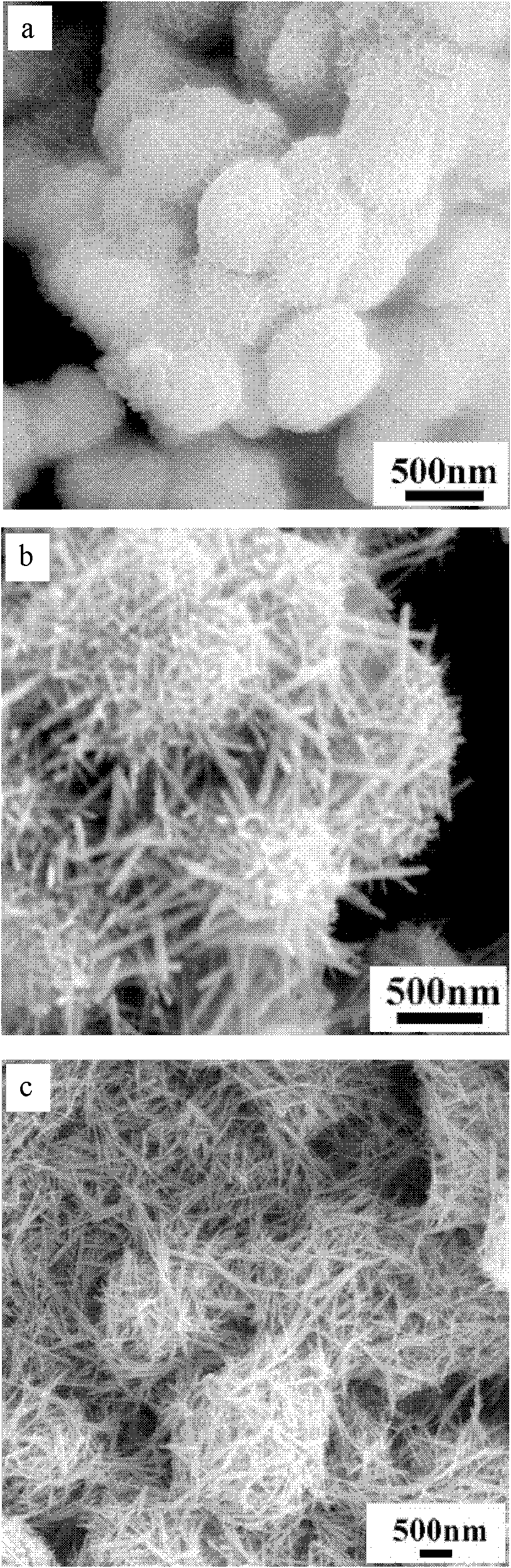

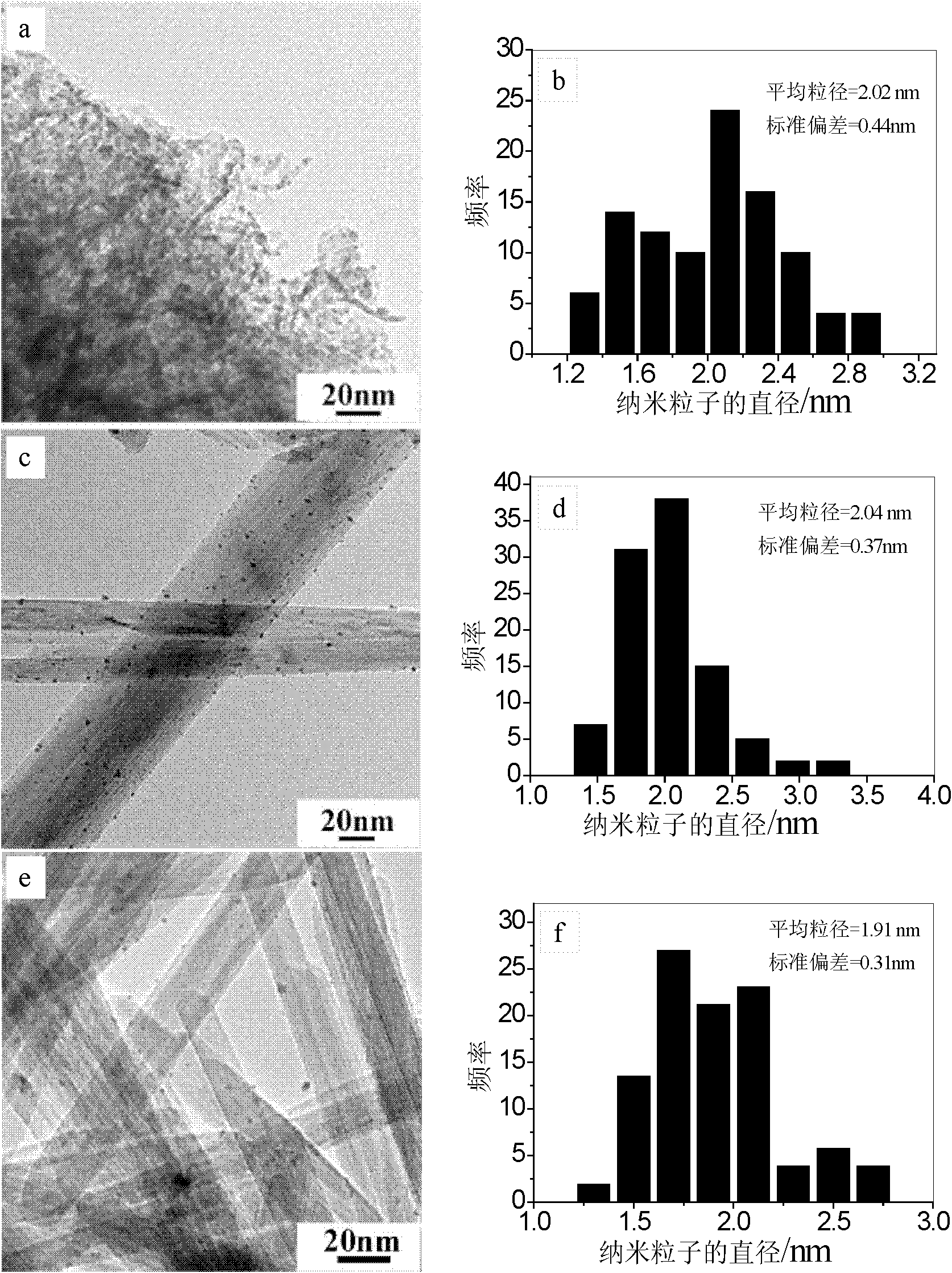

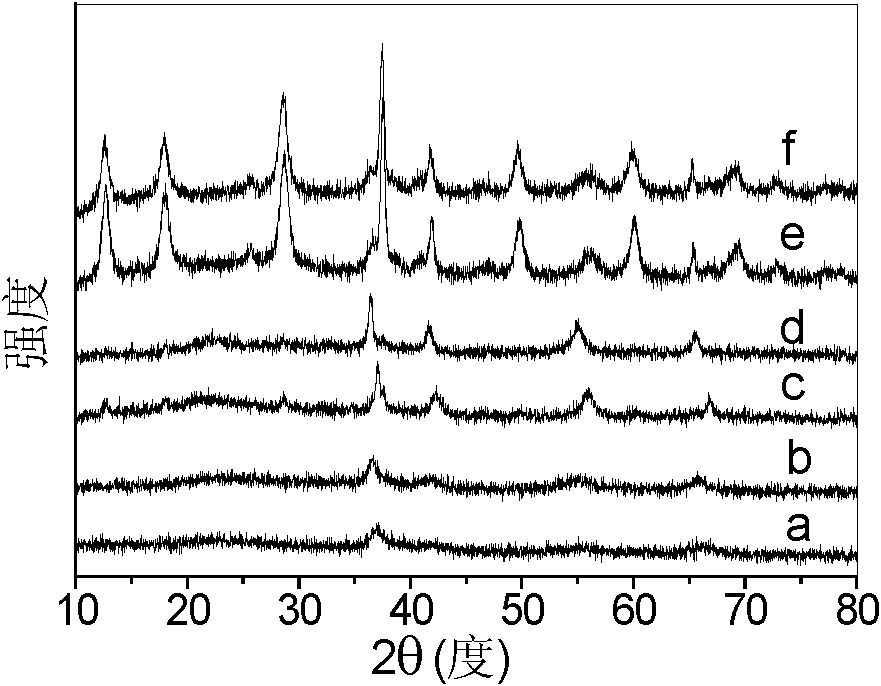

[0054] Cocoon-like MnO 2 Synthesis: Weigh 2.5353g of manganese sulfate monohydrate (MnSO 4 ·H 2 O) Dissolve in 150mL water, after fully dissolving under the condition of stirring, add dropwise the solution containing 1.5803g potassium permanganate (KMnO 4) in 100mL aqueous solution at a rate of about 1-2 drops / s, then stirred and reacted at room temperature for 6 hours, centrifuged the obtained black product, washed the precipitated product with water and ethanol, and finally washed the obtained product at 60 Dry overnight in an oven at °C. Take a small amount of dried samples and redisperse them in ethanol, ultrasonically disperse them under 120w, 40KHz ultrasonic conditions for 5 to 20 minutes, spot them on silicon wafers, stick them on the sample stage of scanning electron microscope, spray gold after drying, and then Observed on a scanning electron microscope, MnO 2 The scanning electron microscope picture of the carrier; the prepared sample was ground into powder and ...

Embodiment 2

[0056] Urchin-like MnO 2 Synthesis: Weigh 1.6902g of manganese sulfate monohydrate and dissolve it in 100mL of water. After fully dissolving under stirring conditions, add 1mL of concentrated sulfuric acid with a mass concentration of 98%, and then use a separatory funnel to add 1.0535g of permanganic acid 66.7mL aqueous solution of potassium, the dropping rate is about 1-2 drops / s, stirred and reacted at 80°C for 24 hours, centrifuged the obtained dark brown product, washed the obtained precipitated product with water and ethanol, and finally washed the obtained product Dry overnight in an oven at 60°C. Get black urchin-like MnO 2 . Take a small amount of dried samples and redisperse them in ethanol, ultrasonically disperse them under 120w, 40KHz ultrasonic conditions for 5 to 20 minutes, spot them on silicon wafers, stick them on the sample stage of scanning electron microscope, spray gold after drying, and then Observed on a scanning electron microscope, MnO 2 The scann...

Embodiment 3

[0058] Bird's nest MnO 2 Synthesis: Weigh 0.5531g KMnO 4 Dissolved in 14mL of water, transferred to a 40mL container lined with polytetrafluoroethylene, and then added dropwise with a separatory funnel containing 0.8873gMnSO 4 ·H 2 O and 0.3 mL of 98% concentrated H 2 SO 4 21mL aqueous solution, the dropping rate is about 1-2 drops / s, hydrothermal reaction at 120°C for 12 hours, centrifuge the obtained dark brown product, wash the obtained precipitated product with water and ethanol, and finally wash the obtained product at 60 Dry overnight in an oven at °C. Take a small amount of dried samples and redisperse them in ethanol, ultrasonically disperse them under 120w, 40KHz ultrasonic conditions for 5 to 20 minutes, spot them on silicon wafers, stick them on the sample stage of scanning electron microscope, spray gold after drying, and then Observed on a scanning electron microscope, MnO 2 The scanning electron microscope picture of the carrier; the prepared sample was gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com