Preparation method for FePt/graphene composite nano-material

A graphene composite, nanomaterial technology, applied in catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of FePt purity that has a great influence, cumbersome process, affecting the catalytic efficiency of fuel cells, etc. Effects that are easy to operate, facilitate application, and synthesize a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Add 100 mg of graphite oxide into 100 mL of ethylene glycol, and ultrasonically disperse for 3.5 hours to obtain solution A;

[0031] 2) Add 0.5 mmol of iron acetylacetonate (hereinafter abbreviated as Fe(acac) 3 ) was added to solution A, stirred and dissolved, and then ultrasonicated for 0.5 hours to obtain solution B;

[0032] 3) Add 0.5 mmol of platinum acetylacetonate (hereinafter abbreviated as Pt(acac) 2 ) into 100 mL of ethylene glycol, stirred to dissolve, and obtained solution C;

[0033] 4) Slowly add solution C dropwise to solution B, and sonicate for 0.5 hours to obtain solution D. The concentration of graphite oxide in solution D is 0.5g / L, and the concentrations of iron acetylacetonate and platinum acetylacetonate in solution D are both 2.5 mmol / L;

[0034] 5) Add 1.5 mmol of 1,2-hexadecanediol to solution D, stir to dissolve it, blow nitrogen gas, and reflux reaction at 197°C for 3 hours; the obtained product is alternately centrifuged with water a...

Embodiment 2

[0039] 1) Add 100 mg of graphite oxide into 100 mL of ethylene glycol, and ultrasonically disperse for 3.5 hours to obtain solution A;

[0040] 2) Add 0.1 mmol of Fe(acac) 3 Add to solution A and stir to dissolve, then sonicate for 0.5 hours to obtain solution B;

[0041] 3) Add 0.1 mmol of Pt(acac) 2 Add to 100 mL of ethylene glycol, stir to dissolve, and obtain solution C;

[0042] 4) Slowly add solution C dropwise to solution B, and sonicate for 0.5 hours to obtain solution D. The concentration of graphite oxide in solution D is 0.5g / L, and the concentrations of iron acetylacetonate and platinum acetylacetonate in solution D are both 0.5 mmol / L;

[0043] 5) Add 0.3 mmol of 1,2-hexadecanediol to solution D, stir to dissolve it and pass nitrogen gas, and reflux reaction at 197°C for 3 hours; the obtained product is alternately centrifuged with water and ethanol, and then vacuum-dried at 60°C After 6 hours, the FePt / graphene composite nanomaterial was obtained.

[0044] ...

Embodiment 3

[0048] 1) Add 100 mg of graphite oxide into 100 mL of ethylene glycol, and ultrasonically disperse for 3.5 hours to obtain solution A;

[0049] 2) Add 0.05 mmol of Fe(acac) 3 Add to solution A and stir to dissolve, then sonicate for 0.5 hours to obtain solution B;

[0050] 3) Add 0.05 mmol of Pt(acac) 2 Add in 100 mL of ethylene glycol, stir to dissolve to obtain solution C; slowly add solution C dropwise to solution B, and sonicate for 0.5 hours to obtain solution D, the concentration of graphite oxide in solution D is 0.5g / L , the concentrations of iron acetylacetonate and platinum acetylacetonate in solution D are both 0.25 mmol / L;

[0051] 4) Add 0.15 mmol of 1,2-hexadecanediol to solution D, stir to dissolve it and pass nitrogen gas, reflux reaction at 197°C for 3 hours; the obtained product is washed with water and ethanol alternately by centrifugation, and then vacuum-dried at 60°C After 6 hours, the FePt / graphene composite nanomaterial was obtained.

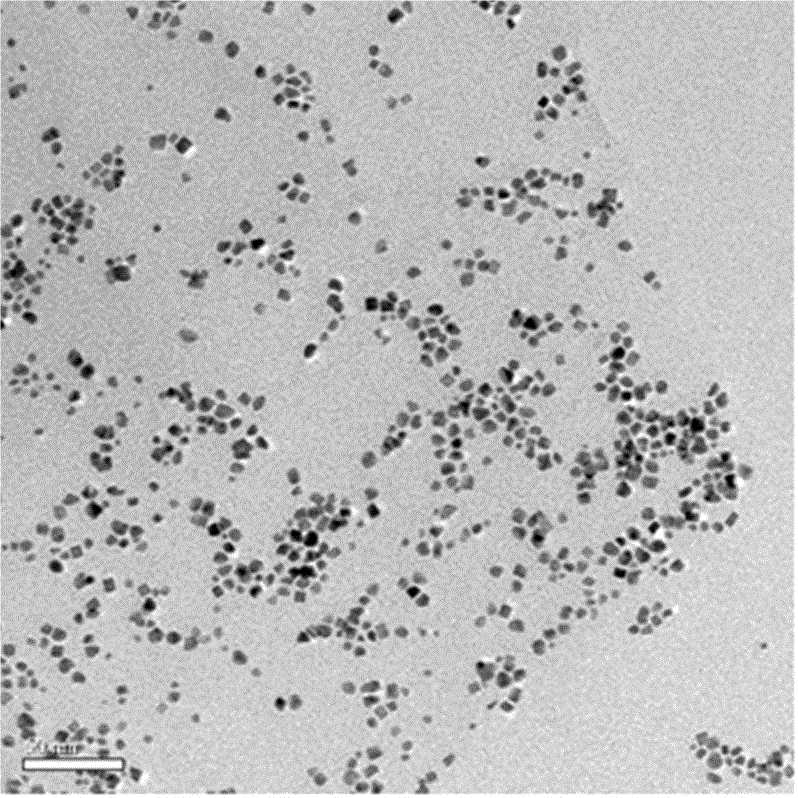

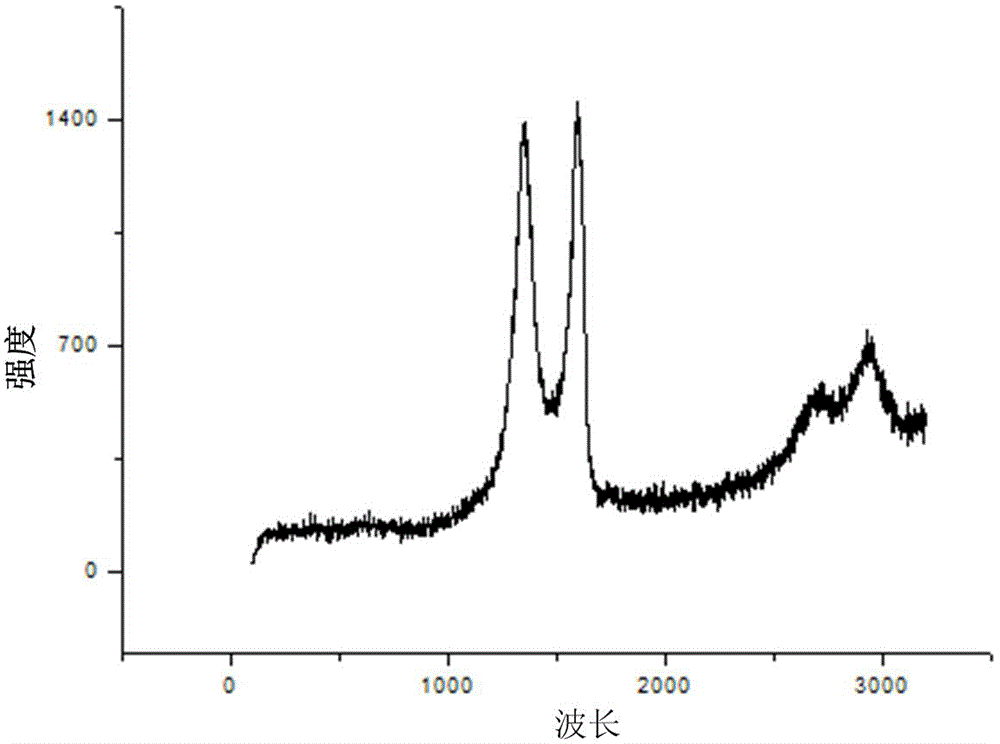

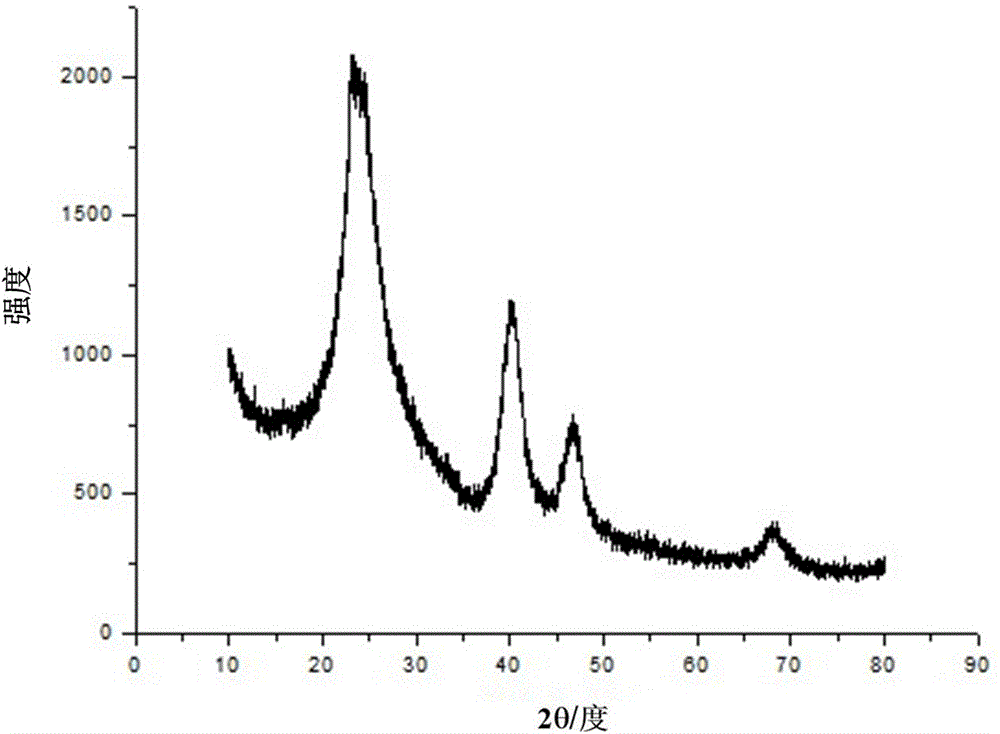

[0052] Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com