Low cost preparation method for needle punched fabrics reinforced quartz composite ceramic radome

A technology of composite ceramics and needle-punched fabrics, which is applied in the field of preparation of low-cost needle-punched fabric-reinforced quartz composite ceramic radome, and can solve the problems of high fiber yarn content, long cycle time, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

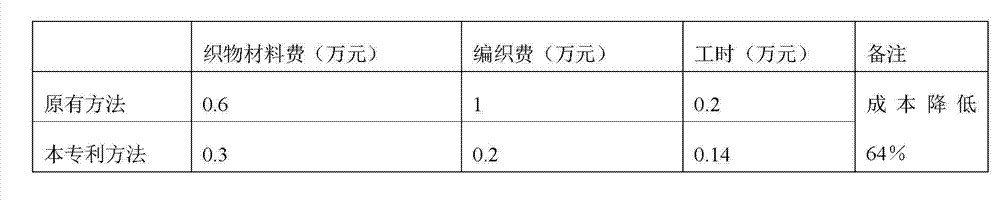

Embodiment 1

[0025] A hemispherical radome process is as follows:

[0026] 1) Design a hemispherical mandrel according to the geometric dimensions of the radome, and puncture the corresponding hemispherical profiling structure fabric layer by layer by needle punching in the order of a layer of quartz cloth and a layer of quartz felt on the mandrel;

[0027] 2) The fabric is boiled in boiling water for 40 hours and then released from the mold;

[0028] 3) Roast the demoulded fabric at 400°C for 4 hours, and then pickle it. The volume ratio of concentrated hydrochloric acid to concentrated nitric acid in the acid solution used for pickling is 3:1;

[0029] 4) Put the acid-washed fabric on the mandrel, repeat the dipping and drying process for 4 times, and then release the mold again. During dipping, the silica sol needs to be vibrated continuously. The dipping process is to place the fabric at a density of 1.10g / cm 3 Immersed in the silica sol for 20min, the drying is to dry the impregnat...

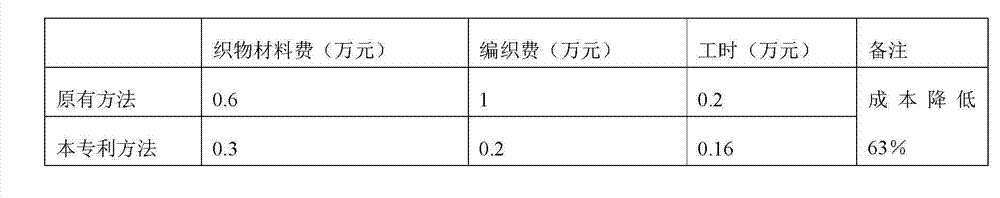

Embodiment 2

[0037] The main technological process of a conical radome is as follows:

[0038] 1) Design a cone-shaped mandrel according to the geometric dimensions of the radome, and puncture the mandrel into a corresponding conical profiling structure fabric by needle punching in the order of the interval between the quartz cloth and the quartz felt;

[0039] 2) The fabric is boiled in boiling water for 20 hours and then released from the mold;

[0040] 3) Roast the demoulded fabric at 700°C for 2 hours, and then pickle it. The volume ratio of concentrated hydrochloric acid to concentrated nitric acid in the acid solution used for pickling is 3:1;

[0041] 4) Put the acid-washed fabric on the mandrel, repeat the dipping and drying treatment twice, and then release the mold again. During the dipping, the silica sol needs to be continuously vibrated. The dipping process is to place the fabric at a density of 1.10g / cm 3 Immersed in the silica sol for 20min, the drying is to dry the impre...

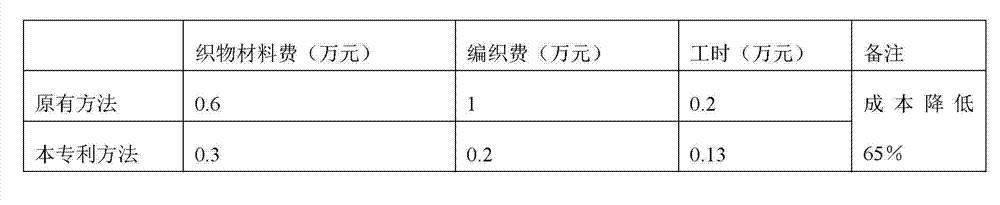

Embodiment 3

[0049] The main technological process of a conical radome is as follows:

[0050] 1) Design a cone-shaped mandrel according to the geometric dimensions of the radome, and puncture the mandrel into a corresponding conical profiling structure fabric by needle punching in the order of the interval between the quartz cloth and the quartz felt;

[0051] 2) The fabric is boiled in boiling water for 30 hours and then released from the mold;

[0052] 3) Roast the demoulded fabric at 550°C for 3 hours, and then pickle it. The volume ratio of concentrated hydrochloric acid to concentrated nitric acid in the acid solution used for pickling is 3:1;

[0053] 4) Put the acid-washed fabric on the mandrel, repeat the dipping and drying process for 3 times, and then release the mold again. During the dipping, the silica sol needs to be vibrated continuously. The dipping process is to place the fabric at a density of 1.13g / cm 3Immersed in the silica sol for 30min, the drying is to dry the im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com