Carboxyl modified polyvinyl alcohol and method for preparing same

A polyvinyl alcohol and carboxyl modification technology, applied in the field of polyvinyl alcohol, can solve the problems of high energy consumption, large pollution, long process route, etc., and achieve the effect of high film strength, high polymerization efficiency and good characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

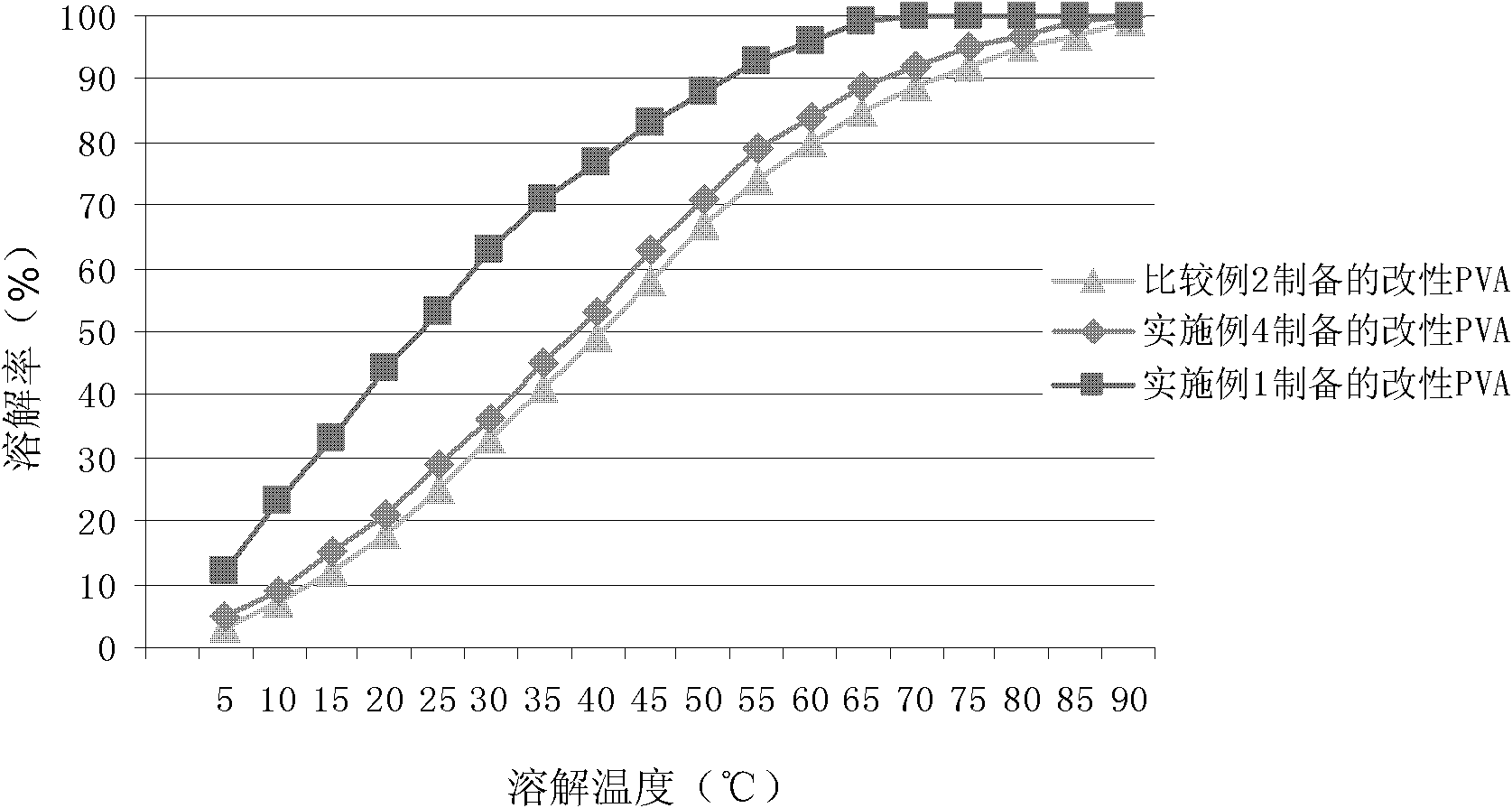

Examples

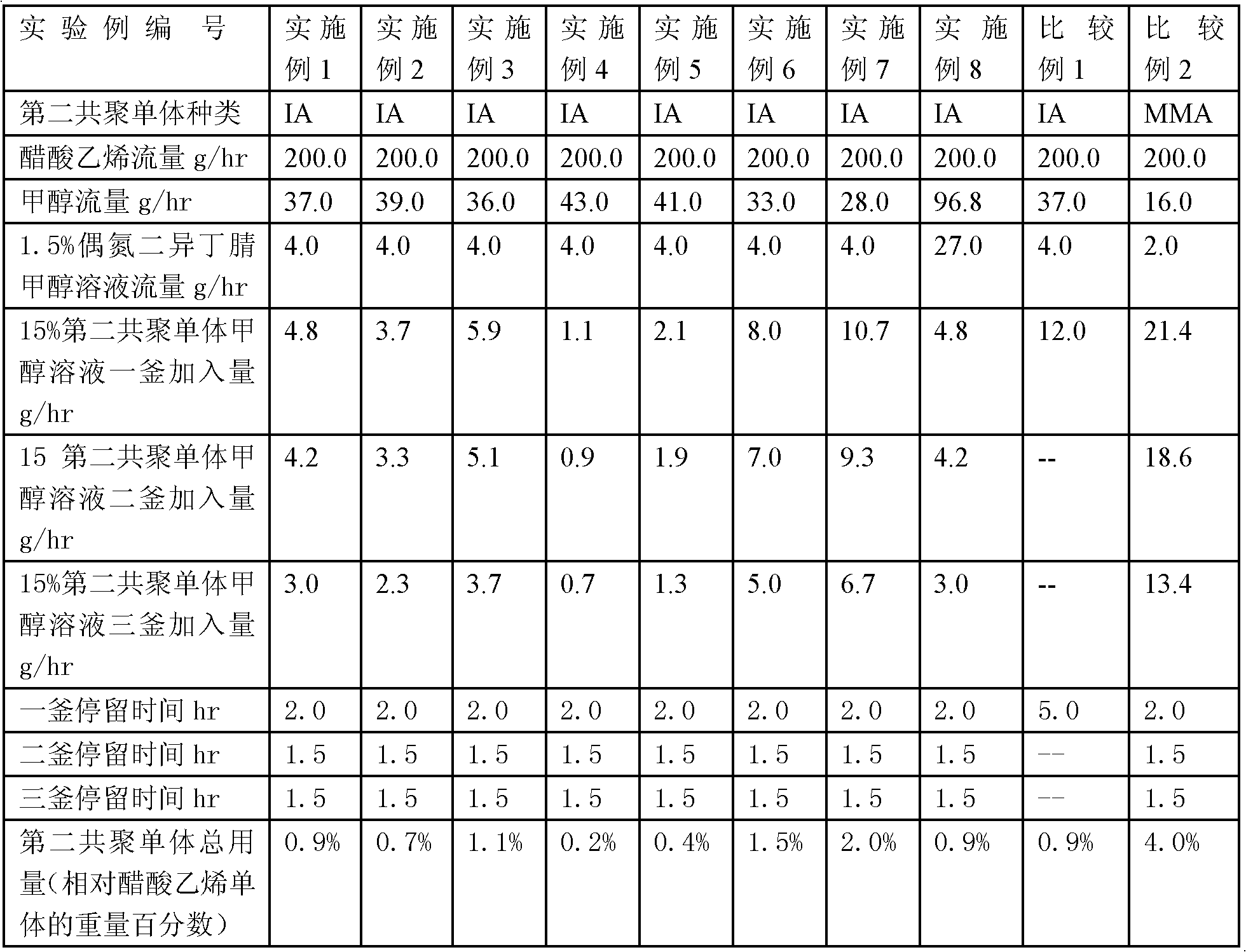

Embodiment 1-8

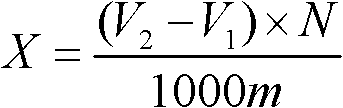

[0057] The preparation method of carboxy-modified polyvinyl alcohol is as follows:

[0058] Arrange three 2-liter jacketed glass polymerization reactors equipped with stirring devices and reflux condensers in series. After replacing the oxygen in these three polymerization reactors with nitrogen, an automatic weighing system is adopted, according to the process conditions in Table 1. Vinyl acetate, methanol, methanol solution with a mass concentration of 1.5% azobisisobutyronitrile, and methanol solution with a mass concentration of 15% itaconic acid are continuously fed into the first polymerization kettle after preheating, and after reaching the specified one-pot residence time Finally, control the liquid level of the first kettle to be constant, and use the gear pump to continuously send the polymerization liquid of the first polymerization kettle to the second polymerization kettle, and simultaneously add the above-mentioned itaconic acid methanol that accounts for 40% of t...

Embodiment 9

[0079] A kind of preparation method of carboxy-modified polyvinyl alcohol:

[0080] (1) Raw material preparation:

[0081] Monomer: vinyl acetate, 0.7wt% maleic acid accounting for the weight of vinyl acetate to prepare a maleic acid ethanol solution with a mass concentration of 10wt%;

[0082] Solvent: account for the ethanol of vinyl acetate weight 20wt%;

[0083] Initiator: Azobisisobutyronitrile ethanol solution with a mass concentration of 2.0 wt% prepared from 0.1wt% azobisisobutyronitrile by weight of vinyl acetate;

[0084] (2) Preparation method:

[0085] Add the vinyl acetate monomer, maleic acid ethanol solution and azobisisobutyronitrile ethanol solution prepared above into the first polymerization kettle, wherein vinyl acetate and azobisisobutyronitrile ethanol solution are all added, maleic acid ethanol The solution is added to account for 50% of the total weight of the maleic acid ethanol solution, the polymerization reaction temperature is 60 ± 5 ° C, and the ...

Embodiment 10-12

[0086] Examples 10-12: Carry out according to the following materials and parameters, and the others are the same as in Example 9. The obtained carboxyl-modified polyvinyl alcohol of the present invention has excellent crosslinking reaction performance, water solubility, dispersion performance, rheological performance, Anti-"skinning" properties and low foaming.

[0087]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com