Waveguide mode-locked laser

A mode-locked laser and waveguide grating technology, applied in the field of lasers, can solve the problems of reducing the high integration of waveguide mode-locked lasers and technical barriers to optical integration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

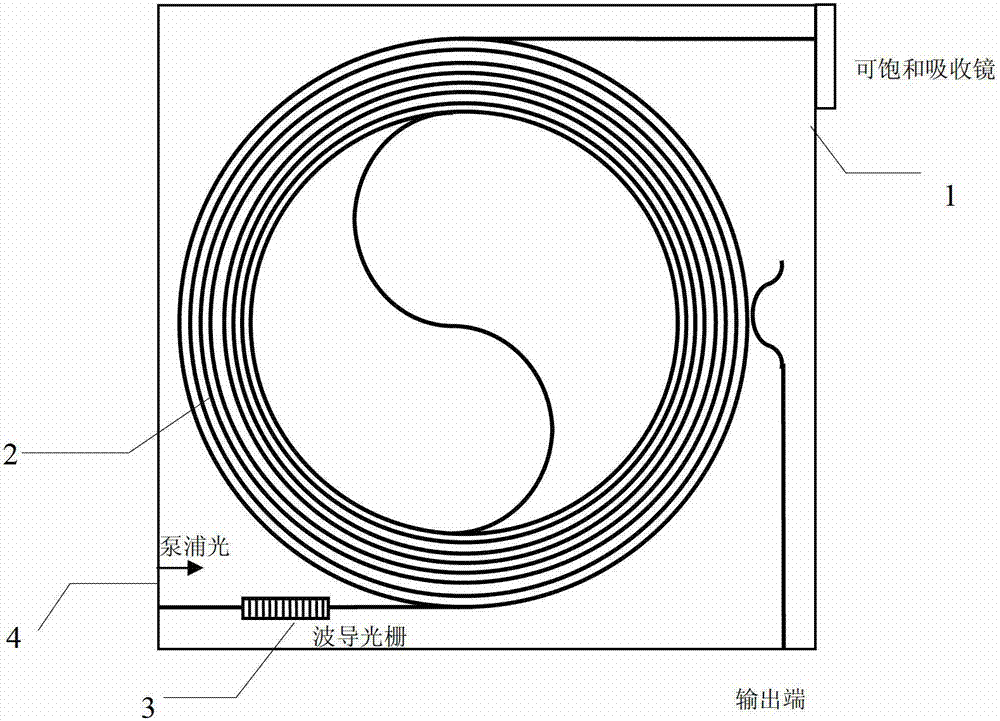

[0019] see figure 1 , the waveguide mode-locked laser of the present invention is mainly composed of 4 parts, a semiconductor saturable absorbing mirror 1, a waveguide gain medium 2, a waveguide grating 3, a laser diode array pump source 4; a semiconductor saturable absorbing mirror 1 and a waveguide grating 3 are respectively arranged at both ends of the waveguide gain medium 2, and the laser diode array pump source 4 is arranged on the waveguide grating. The semiconductor saturable absorbing mirror 1 is fixed to the output end of the waveguide gain medium 2 through a precision control platform, and the semiconductor saturable absorbing mirror 1 is fixed with special glue, thereby realizing the saturable absorbing mirror 1 It is integrated with the waveguide to meet the structure of the whole waveguide.

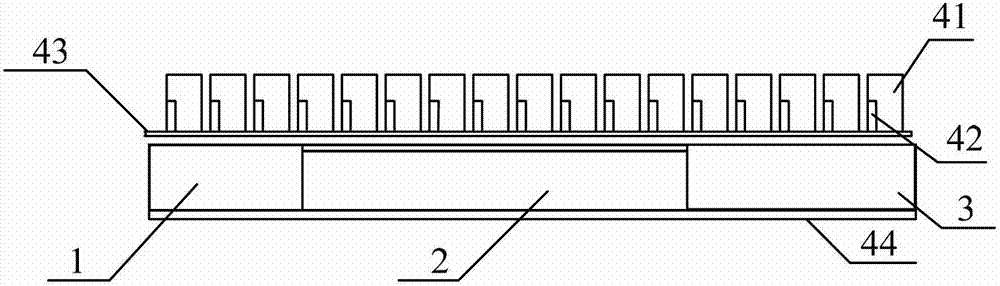

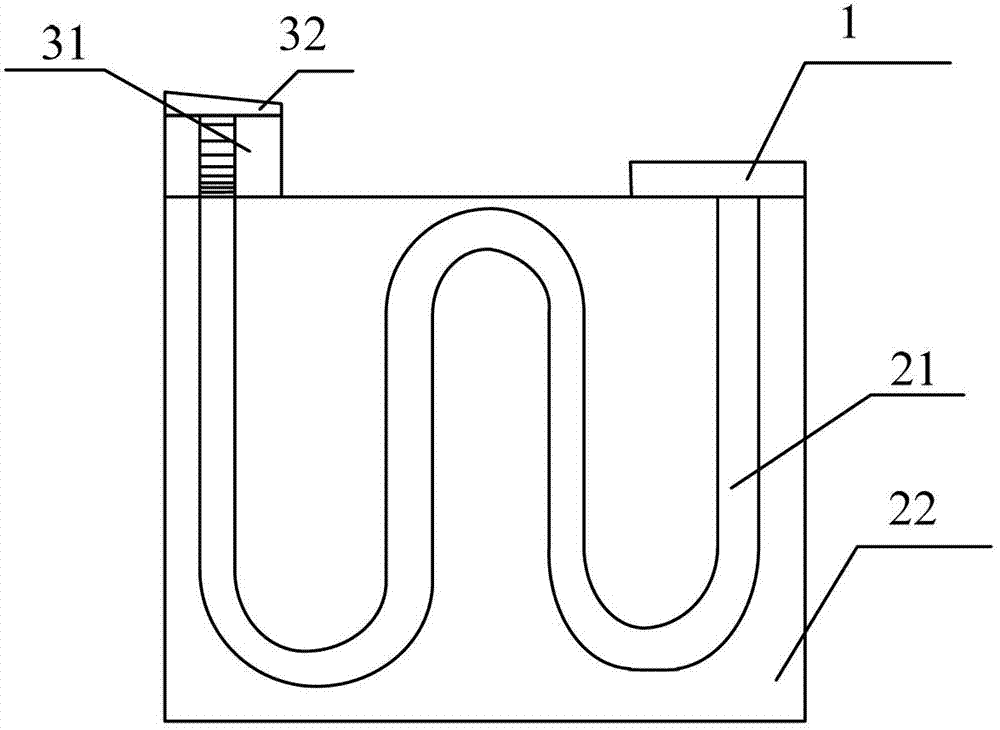

[0020] see figure 2 , image 3 , the waveguide gain medium 2 is a piece of doped material with a thickness of 220 μm, a width of 11 mm, and a length of 60 mm. The bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com