Preparation method of three-dimensional ordered macroporous composite material

A composite material, three-dimensional ordered technology, applied in the direction of nanotechnology, chemical instruments and methods, carbon compounds, etc. for materials and surface science, can solve the problems that cannot reflect the performance advantages of carbon nanotubes, large pores are easy to deform and collapse, and flexibility Poor support and other problems, to achieve the effect of increasing the electrochemical active area, increasing the loading capacity, and increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

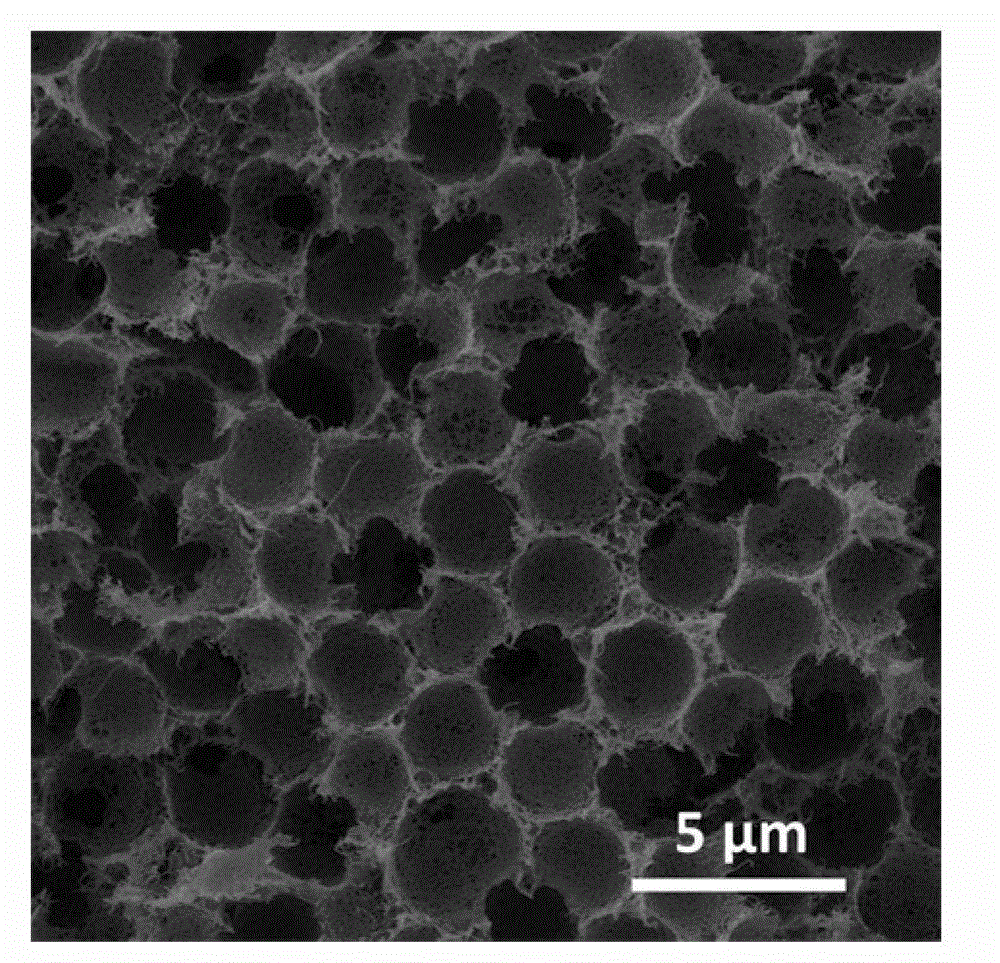

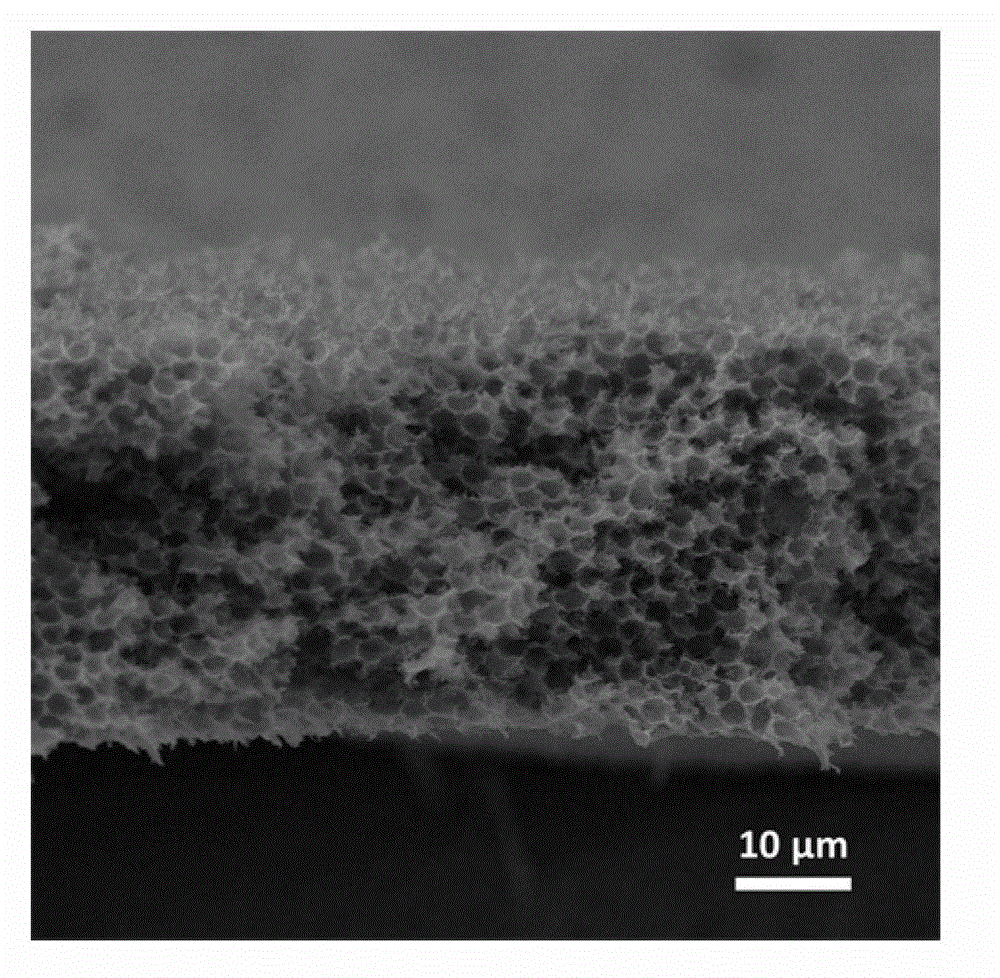

[0029] The preparation method of this three-dimensional ordered macroporous composite material comprises the following steps:

[0030] 1. Mix carbon nanotubes and sacrificial templates in a dispersant;

[0031] II. Co-precipitating the carbon nanotubes described in step I and the sacrificial template;

[0032] III. Submerging the coprecipitate of the carbon nanotubes and the sacrificial template described in step II in a binder to obtain a binder;

[0033] IV. After drying the adhesive in step III, remove the sacrificial template with an etching solution.

Embodiment 1

[0035] In this implementation, multi-walled carbon nanotubes and polystyrene are used as sacrificial modules, and the carbon nanotube dispersant is prepared with ionic surfactant sodium dodecylbenzenesulfonate (LAS) and deionized water, wherein the mass content of LAS is 1 %. In addition, polyvinyl alcohol is used as the binder, and tetrahydrofuran is used as the etchant.

[0036] In the first step, take 2 mg of multi-walled carbon nanotubes and add them into 2 mL of dispersant, and disperse the multi-walled carbon nanotubes evenly with an ultrasonic instrument. Then take 3.4 mg of polystyrene (PS) balls with a diameter of 2 microns and add them into the dispersed carbon nanotube solution, and use an ultrasonic instrument to disperse the PS balls evenly.

[0037] In the second step, the mixture of carbon nanotubes, PS balls and dispersant is diluted 100 times with deionized water, and then dispersed evenly with an ultrasonic device. Then immediately filter the diluted mixtur...

Embodiment 2

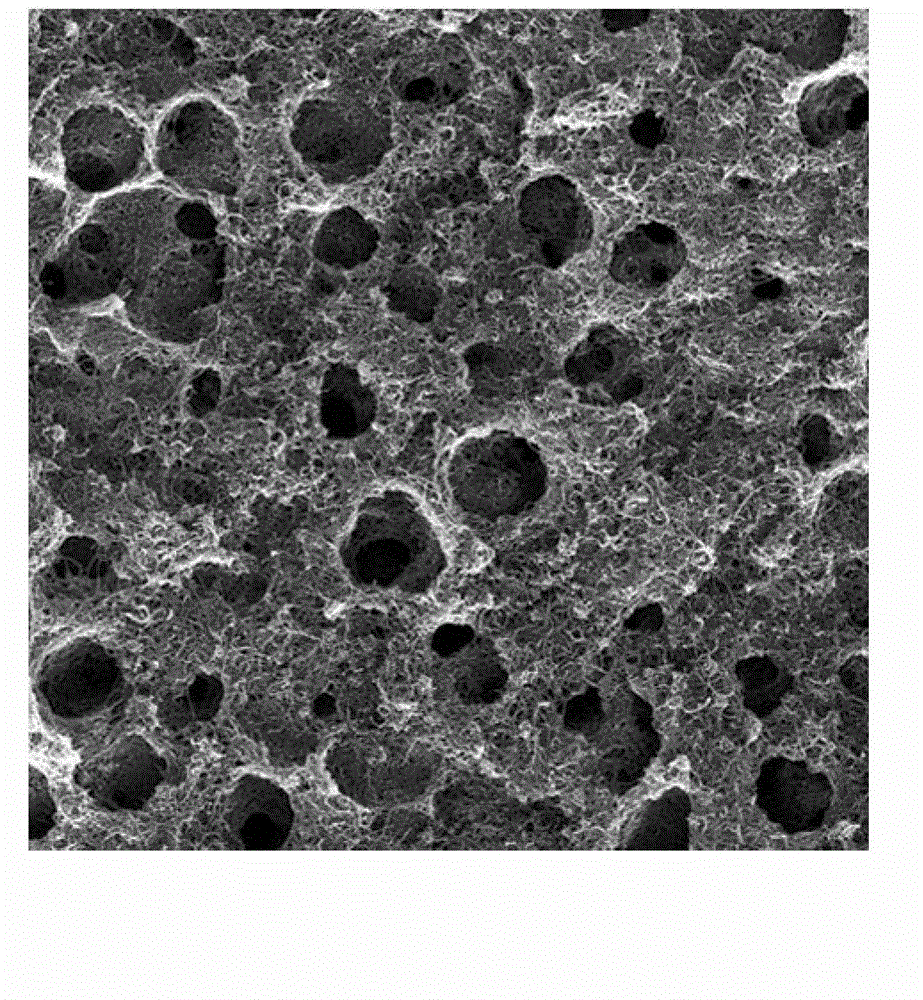

[0040] Compared with Example 1, the difference of this example is that a deionized aqueous solution with a mass content of 0.2% polyvinyl alcohol (PVA) is used as a binder. The single-walled carbon nanotubes and PS spheres were mixed and placed in the binder, and heated to 90°C for 2 hours. Finally, acetone was used as an etchant to remove the PS spheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com