Synthesis method of basic zinc chloride monocrystal nanorods

A single-crystal nanotechnology, synthesis method, applied in zinc halide, nanotechnology, nanotechnology and other directions, can solve the problems of uneven size, irregular distribution, less research, etc., to avoid the increase of reaction energy consumption and regular morphology. Uniform, simple process route effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

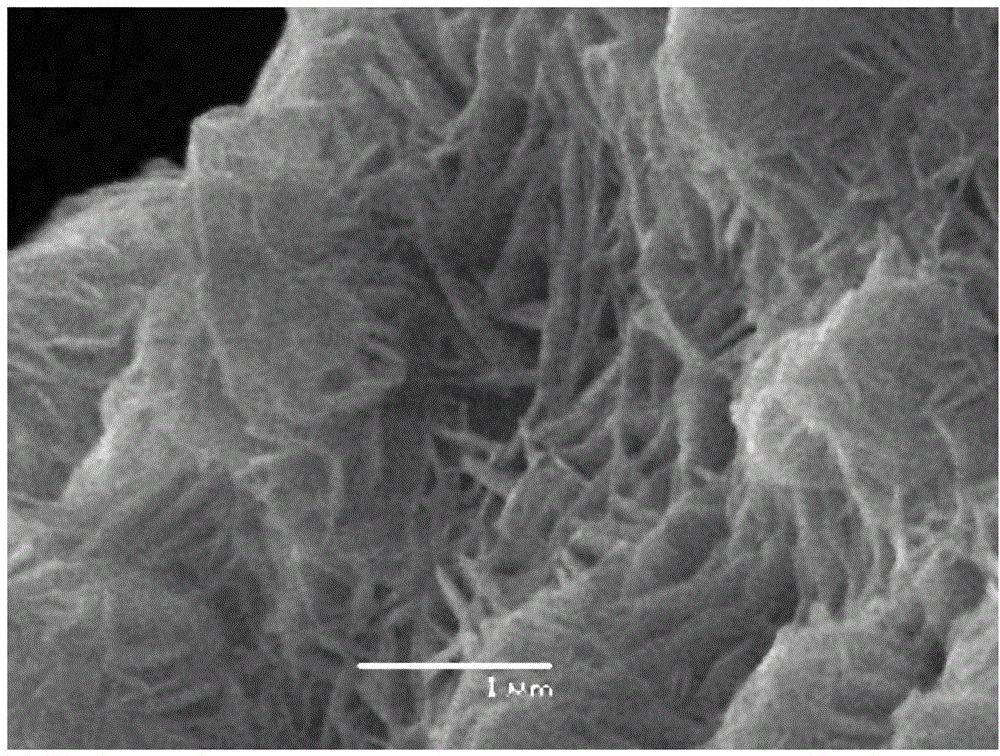

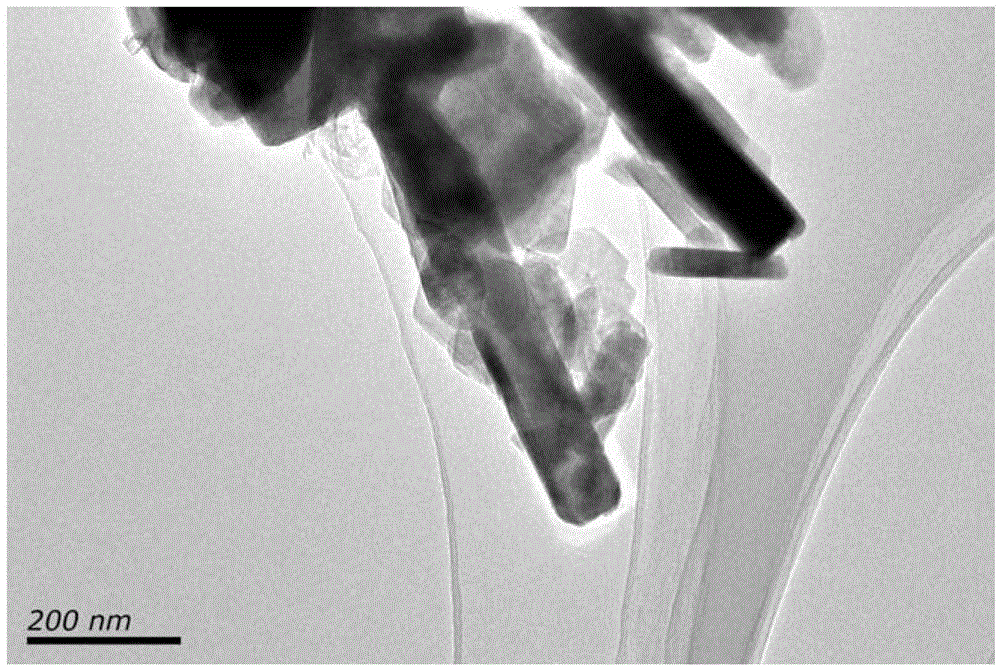

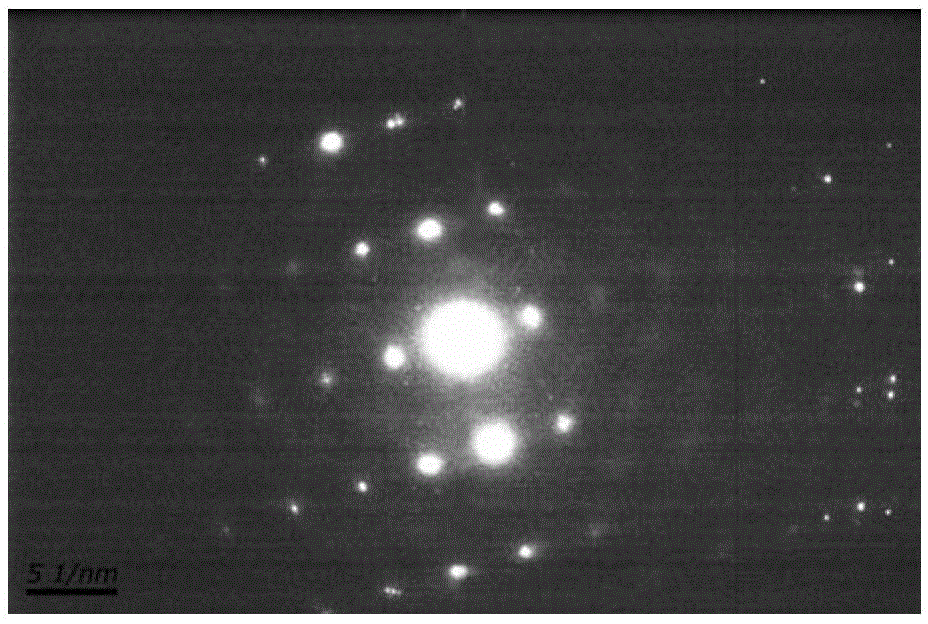

[0027] A method for synthesizing basic zinc chloride single crystal nanorods of the present invention, comprising the steps of: preparing a concentration of 0.16mol L -1 200mL of zinc chloride solution, under the condition of magnetic stirring, ammonia water was added dropwise with a material ratio of 1:5. After reacting for 30min, the resulting suspension was centrifuged, and the sample was washed with deionized water and then centrifuged. Repeat three times, and add the sample amount 10 times the volume of deionized water, heated in an oven at 80°C for 2 hours, then allowed to stand for 16 hours. Wash the sample with absolute ethanol and centrifuge, repeat three times, and dry in an oven at 40°C for 6 hours to obtain a white basic zinc chloride single crystal nanorod powder with a uniform shape, a diameter of about 70 nm, and a length of about 400 nm, as shown in figure 1 SEM photographs and figure 2 The transmission electron microscope photo is shown.

[0028] At the sa...

Embodiment 2

[0030] A method for synthesizing basic zinc chloride single crystal nanorods of the present invention, comprising the steps of: preparing a concentration of 0.125mol L -1 200mL of zinc chloride solution, ammonia water was added dropwise with a material ratio of 1:3 under magnetic stirring conditions, and after 20 minutes of reaction, the resulting suspension was centrifuged, and the sample was washed with deionized water and then centrifuged. Repeat three times and add the sample amount 15 times the volume of deionized water, heated in an oven at 80°C for 2 hours, then allowed to stand for 18 hours. The sample was washed with absolute ethanol and then centrifuged, repeated three times, and dried in an oven at 40°C for 6 hours to obtain a white basic zinc chloride single crystal nanorod powder. The morphology and properties of the obtained product were similar to those in Example 1.

Embodiment 3

[0032] A method for synthesizing basic zinc chloride single crystal nanorods of the present invention, comprising the steps of: preparing a concentration of 0.16mol L -1 200mL of zinc chloride solution, ammonia water was added dropwise with a material ratio of 1:7 under magnetic stirring conditions, and after 20 minutes of reaction, the resulting suspension was centrifuged, washed with deionized water and centrifuged, and repeated three times. 20 times the volume of deionized water, heated in an oven at 80°C for 2 hours, then allowed to stand for 20 hours. The sample was washed with absolute ethanol and then centrifuged, repeated three times, and dried in an oven at 40°C for 6 hours to obtain a white basic zinc chloride single crystal nanorod powder. The morphology and properties of the obtained product were similar to those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com